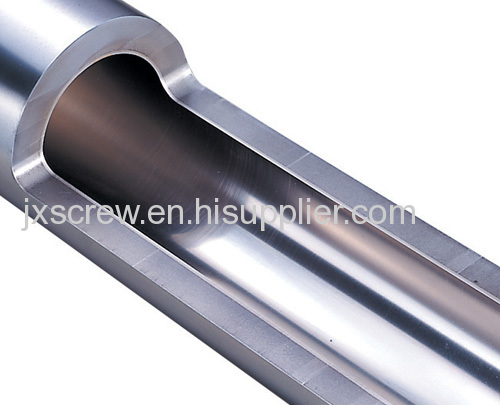

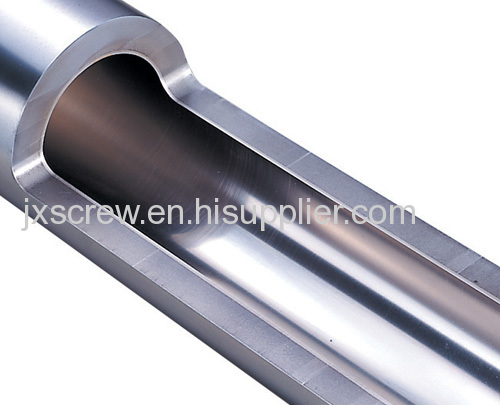

bimetallic screw and barrel

•Detailed Specification

| BaseMaterial | 1)38CrMoAlA(JISSACM645) 2)Cr12MOV(JIS SKD-11) 3)4Cr5MoSiV1(JIS SKD-61)4)42CrMo(AISI4140) |

| BimetallicAlloy Materials | 1)Fe-basedalloy2)Ni-based alloy/Deloro alloy 3)Co-based alloy4)NiCo-basedalloy 5)Tungsten carbide/Wolfram carbide |

| Double-alloylevel | LevelA - containing Tungsten of 40% LevelB - containing tungsten of 25% LevelC - containing tungsten of 9.5% |

| SurfaceTreatment | HeatTreatment HighFrequency Treatment Nitridingtreatment(120 Hours) Depth of Nitrided Layer: 0.5-0.8mm Hardness of NitridedLayer: 900-1020Hv (HRC56°-65°) HardChrome Plating treatment: Thicknessof Hard Chrome Plating Layer: 0.05-0.10mm Hardnessof Hard Chrome Plating Layer: ≥950HV Nickelalloy plating.treatment: BimetallicBarrel/Cylinder: Centrifugal Casting (Inlay Alloy) BimetallicScrew: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° |

| Basicinformation | Roughnessof the surface:Ra0.4um Linearityof the screw: ≤0.015mm Linearaxis limit: ≤0.02mm Hardnessafter Hardening & Tempering: HB240-280 Fragilityof Nitration:≤Two class |

| MaterialApplication | 1)GeneralPlastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA+ GF(Glass Fiber) 4)Flame-resistantReinforced Plastics 5)ModifiedEngineering Plastics 6)Allkinds of Mixed Recycled Material(in Scrap or Granule),etc |

| GeneralTerms | Meansof transport: Ocean,Air,Express Productiontime: About 25 days after we receive the deposit and lead time willdifferent according to the order quantity! |

| Ourproducts advantages | 1)Highproductivity 2)Wonderful plasticizing 3)low energy consumption4)Wearable and Durable 5)Fastand On time delivery6)Best customerservice! |

•Production Steps

CustomerOrder--ProductDesign(CustomerDrawing)—ProductionFlowArrangement—

MaterialProcurement—Hardening&Tempering—Drilling—RoughTurning—RoughThread

Rolling(AlloySprayWelding)—Alignment—FineThreadRolling—Mixing—Alignment—High

FrequencyTreatment—Alignment—Polishing—Grinding—120HoursNitridingTreatment—

AcidPiclking—Polishing—ChromePlating—O.D.Grinding—Packaging&Shipping!

• Screw &Barrel Display

• Products Application

• Mahine Application

•Pictures of workshop

Advantages for JinXing Plastic MachineryManufactory

1.Over 30 years Experience OnManufacturingScrew Barrel

2.Over 20 years design experience perfessional engineersservice for you

3.Over 20 years goodcooperation relationship with most of our customers

4.24-Hours Online Service byemail or online-chat tools(Before&After sale service)

5.Prodution base on yourdrawing or specially design screw&barrel for you

6.Located in China's Screw Town - Jintang Town in Zhoushan City, near to Ningbo Port and Shanghai Port.

Tellus your request, we will do the rest !