Back flush screen changer for plastic recycling water-ring cut granulator

This kind of back flush screen changer DHZX series is the latest product if our company , and we owns the patent in China, And also, we applied the patent in America and Europe, now we get the patent annoucement.

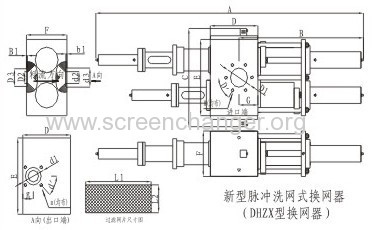

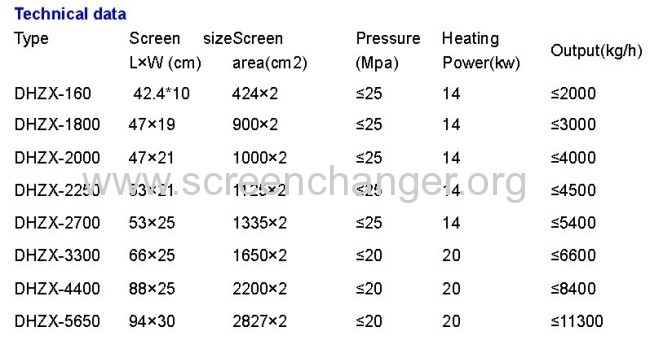

Look at the specification of the back flush screen changer

Our back flush screen changer is different from the backflush screen changer from BKG Group, the filter screen is not round, and not the breaker plate embedded on the piston.

And our back flush screen changer the screen is wrapped on the slide bar with holes.

The advantages of this kind of screen changer:

1, the filter screen area is large, form 365cm2 to 11000cm2 .this large screen area meets the high -yield device, especial for the output up to 2500-3000kg/h.

2, self- cleaning system make it's easy for worker operation ,no need to replce the screen, we just need to

remove the dirty material on th screen. and the scren can be recycle used for more than 100 times.

3, this kind of backflush screen changer can not only filter impurities, but also can greatly improve the plasticizing and homogenization effect of the raw material, make the product surface smoothness and higher quality

4,Percentages of waste materials are very low (1-2%) in case the scraping method is used, whilst if the backwash method is preferred, percentages can reach a maximum of 5%.

Commissioning

At the requirement of customer, seller should send technicians to install and debug the screen changer to the die at site of Buyers, Travelling expenses and accommodation fee should be borne by Buyers.

Warranty

"three guarantees"(return, replacement, repair) of all the spare parts for one year. Travelling expenses and accommodation fee for"three guarantees" will be borne by users.

Application fields:

1. Applicable to all the kinds of plastic products. Specially in the recycling and granulation combined with high impurities, such as PE/PP/PS/ABS/PET/PA/etc.

2. Applicable to the production line of chemical fiber, rubber, collosol, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture.

Our advantages

We are specialized in the research and manufacturing of melt filtration device/screen changer for more than 20 years. With strong scientific research team and mature technology; hold many international and national invention patents.

Our items can not only filter impurities, but also can greatly improve the plasticizing and homogenization effect of the raw material, make the product structure more homogeneous and product surface smoothness and quality much better, energy-saving and consumption-reducing, output- increasing and labor-saving