Two chanel screen filter for polymer melt filtration

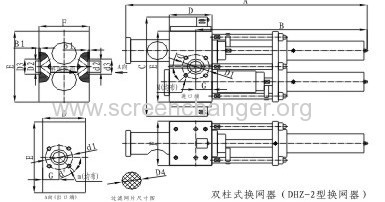

Double piston screen changer

The two chanel screen filter for polymer melt filtration also called double pistion screen changer ,continuous screen changer .

This kind of screen changer is consists of the body of the screen changer, heater, hydraulic unit , electric controlling cabinet( pressure sensor, temperature controller, warning device are included)

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 6 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 8 | 100--350 |

DHZ-2-155 | Screen wrapped on the piston(300*65) | 195 x 2 | 10 | 300-800 |

DHZ-2-230 | Screen wrapped on the piston(420*100) | 420 x 2 | 10 | 400-1200 |

DHZ-2-160 | Φ135 | 143 x 2 | 10 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 12 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 10 | 500-1500 |

DHZ-2-1800 | square screen be wrapped on the slide bar | 900x2 | 10 | 1000-2000 |

DHZ-2-2000 | Square screen be wrapped on the slide bar | 1000 x2 | 12 | 1000-3000 |

Performace of this kind of two chanel screen filter for polymer melt filtration

1, It can match with extruders of different design. It is applicable to process with most polymers at high output.

2, Double-channel nonstop screen changer work alternatively, which can change the screen with minimum melt pressure fluctuating and production interrupting.

3, Two stages air vent for the hydraulic system to eliminate bubbling in polymer flow.

4, Superior sealing system completely eliminates polymer leakage.

5, External safety cover gives better appearance and safe protection.

6, It is equipped with circular\elongated or U- shaped screens, for enlarged filtration area.

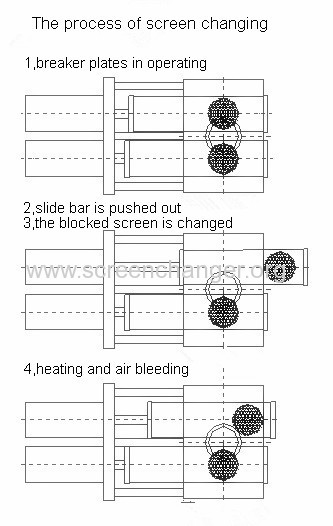

screen chaning process of this two chanel screen filter for polymer melt filtration

To change the screen, the pistons are ejected from the housing one after the other using hydraulic cylinders. Once replaced, they are returned to their production position in the same way. During the brief screen change process, the melt flows continuously through the other piston, thereby ensuring the system's constant operation

Applications

cast film (Bubble pack\ Medical\Food Wrap)

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers

Our main competitors:

1, Kreyeborg GmbH

2,Nordson Xaloy

3, JSW,the Japan steel works

4,PSI-polymer system

5,Gneuss melt filtration system

6,e-bay

Compare with them, we have many unique advantages

1, over 20 years R&D experience in the polymer melt filtration .

2, high quality product with lower price

3, quick delivery time, as quickly as one week

4, full time service, 24 hours telephone online: +008613633833227