Welcome to our wedsite

Jtp Mould is known as one of the best manufacturers and exporters for plastic injection moulds for household articles, chair mould, pallet mould, crate mould, automotive mould and so on. Our moulds are mainly exported to Italy, Australia,Saudi,Arabia,Jordan,Argentina,Colombia,India, Malaysia, Philippines and other 20 countries.

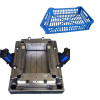

1. More detailed about the good quality plastic crate mould

name | good quality plastic crate mould |

| mould material | 718 |

| cavity | 1 cavity |

| runner | hot runner |

| mould design | 3D/2D |

| design days | 1 day |

| mould life | 1 million shots |

| plastic material | HDPE |

| injection system | direct gate |

| payment | 40% of deposit by L/C T/T 60% of balance by L/C T/T |

| delivery time | 50 days |

| specification | depends on customers' demand |

2. related products & moulds from JTP MOULD

3.Procedure of mould making

Step 1 place the order & receive the down payment

Step 2 Design and make the drawing( products& moulds)

Step 3 Customer check & confirm

Step 4 Steel material purchase

Step 5 Machine process(CNC, sparking machine, boring machine) & mould makers install

Step 6 Mould testing

Step 7 Send the samples to check

Step 8 Receive the balance & mould shipment

4.our main business line

1. Household Mould:Chair Mould,Chair Mould,Stool Mould,Table Mould,Bucket Mould,Basket Mould,Food Container Mould,Dustbin Mould, etc.

2. Industrial moulds: pallet mould, crate mould,Beer Crate Mould paint container mould ,etc.

3. packaging moulds:blowing mould, bottle mould, cap mould,etc.

4. PET Preform Mould

5. Pipe Fitting Mould:PPR pipe fittings,PE,PVC pipe fittings.

6. Thin Wall Mould:thin wall cup, thinwall tablewares, etc.

7. Home Appliance mould

8. Automotive parts:bumper mould, dashboard mould,etc.

9. Industrial Part Mould

10.Syringes Mould

5.our advantages

1. Good quality

2. Delivery on time

3. Rich experiences for mould making

4. Competitive price

5. Good After-sale service

6. Professional English communications with customer

6.offers you

response on Email, telephone calls or fax in-time

supply the quotation and mould designs in-time

communication on the technical points in-time

sending pictures for the mould machining progress and mould finishing schedule in-time

mould test and sample delivery in-time

.jpg)