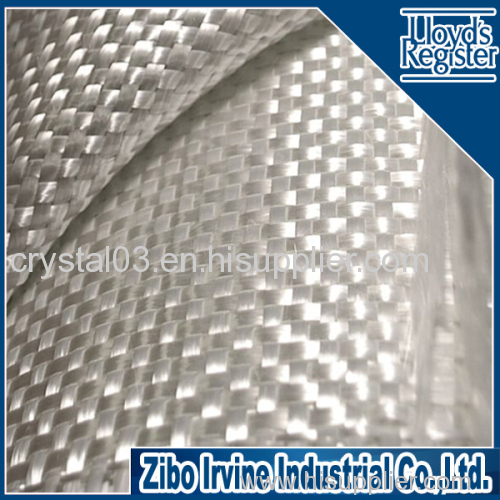

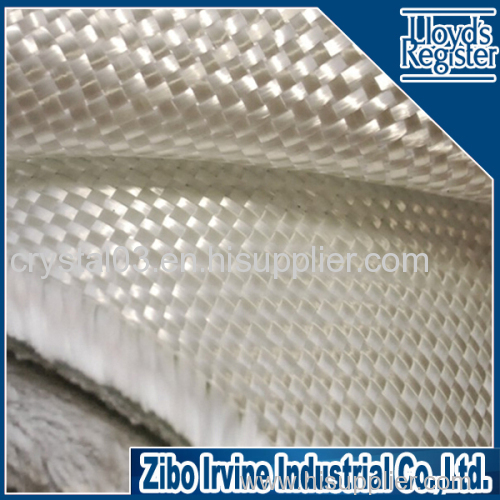

E glass WR800 woven roving japan fiberglass boat

Description

EGlass Woven Rovings is a bidirectional fabric made by interweaving direct rovings. Warp and weft rovings are aligned in a parallel and flat manner, resulting in uniform tension. E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes. Densely aligned fibers, resulting in high dimensional stability and making handling easy.

Our Produc

specifications

Product code | Area weight | Density warp*weft | Tex | Combustible content |

EWR200 | 200 | 4.6*4.6 | 200*200 | 0.4-0.8 |

EWR 270 | 270 | 4.6*4.1 | 300*300 | |

EWR360 | 360 | 3.2*1.8 | 600*900 | |

EWR400 | 400 | 3.6*3.2 | 600*600 | |

EWR450 | 450 | 3.2*2.8 | 600*900 | |

EWR500 | 500 | 2.2*2.0 | 1200*1200 | |

EWR580 | 580 | 2.6*2.2 | 1200*1200 | |

EWR600 | 600 | 2.6*2.4 | 1200*1200 | |

EWR800 | 800 | 2.0*1.6 | 2400*2400 |

Product features

Complete and fast wet-out

Easy handling

Good mechanical properties

Good moldability

High productivity

High strength of parts

Uniform tension

Resin Compatibility:

Epoxy (EP)

Phenolic resin

Unsaturated polyester

Vinyl ester

Package

Doff: 270 310 | ||

Doff outside diameter | 270 mm (10.6 in) | 310 mm (12.2 in) |

Doff inside diameter | 100 mm (4 in) | 100 mm (4 in) |

Doff height | 260 mm (10 in) | 260 mm (10 in) |

Doff weight | 17 kg (37.4 lb) | 23 kg (50.7 lb) |

Pallet: | ||||

Number of layers per pallet | 3 | 4 | 3 | 4 |

Number of doffs per layer | 16 | 16 | 12 | 12 |

Number of doffs per pallet | 48 | 64 | 36 | 48 |

Net weight | 816 (1797.3 lb) | 1088 kg (2396.5 lb) | 828 kg (1825.4lb) | 1104 kg (2433.9 lb) |

Length | 1120 mm (44 in) | 1120 mm (44 in) | 1270 mm (50 in) | 1270 mm (50 in) |

Width | 1120 mm (44 in) | 1120 mm (44 in) | 960 mm (36 in) | 960 mm (36 in) |

Height | 940 mm (37 in) | 1180 mm (46.5 in) | 940 mm (37 in) | 1180 mm (46.5 in) |

Storage

Unless otherwise specified, fiberglass products should be stored in a dry, cool and moistureproof area. Room temperature and humidity should always be maintained at 15°C – 35°C,

35% – 65% respectively.

Best used within 12 months after production date. Fiberglass products should remain in their

original packaging until just prior to use.

To ensure safety and avoid damage to the product, the pallets should not be stacked more than

two layers high. When the pallets are stacked in two layers, care should be taken to correctly

and smoothly move the top pallet.

Our Factory

Our Advantages:

a.We are the manufacturer, not only trading company, price will be much competitive

b.We have produced strickly in according to the customers' request.

c. Our operational theme of "good Quality , high Credibility&best service".

Why Us:

1,We have factory and can offer you direct price

2,We can promise you a short lead time ( 10-15days )

3,We have good after-sale service offered, please get back if you got question.

4,We are specializing in the production and sale of fiberglass and other related products.

5,We have well-trained & experienced staff are to answer all your inquiries in English of course.

6,We have gain high reputation among our customers and share more and more of the packaging material market.

7,Your business relationship with us will be confidential to any third party.

Every year we export containers all over the world. With our good quality products at competitive price and our professionalism in packaging material.

Company Description

Zibo Irvine IndustrialCo., Ltd. (est. 2010), is a new manufacturer and construction materials enterprise which specializes in unsaturated polyester resin, silica fume, chemical raw materials, and polymer composite materials. Our products include glass fiber yarn, glass fiber products, unsaturated polyester resin, and micro silicon powder (92%, 94%, 96%). Our main markets are Southeast Asia, the Middle East, Europe, and the United States of America, and industries we involve are chemical corrosion resistance, sanitary ware, household appliances, aerospace, artificial stone, refractory materials, and concrete construction. We adhere to principles of management integrity, continuous development and innovation, and cooperation with customers to meet their goals. We are committed to using advanced technology and scientific management to create first-class products.

Product list:

fiberglass roving for spray-up

fiberglass roving for SMC

fiberglass roving for thermoplastics

fiberglass roving for filament winding

fiberglass roving for pultrusion

fiberglass roving for Continuous panel molding process

fiberglass roving for gypsum

fiberglass chopped strand mat

fiberglass for woven roving

fiberglass for sleeper train

fiberglass for hobas pipes