Magnetic separator introduction :

Magnetic separator is widely used to separate the raw materials with different magnetic rigidities. It works under the magnetic force and machine force. Magnetic separators are designed to recover ferromagnetic materials, and they are available in designs and sizes to provide solutions for all applications.

Magnetic separator application

Magnetic Separator are available in cyclic design with vessel whose diameters are smaller than 3mm. Magnetic Separator is a kind of efficient equipment for processing fine, feebly magnetic minerals, such as hematite, limonite, wolfram, limonite, and tantalum-niobium, etc. In recent years, it is also more and more applied in purifying quartz, feldspar and nephrite. Its magnetic system is a ring-shape chain closed magnetic circuit with energizing coils made of copper tube and cooled internally by water. Grooved plates made of magnetic conductive stainless steel are used as magnetic matrix.

Magnetic separator are applied for mining, coal preparation plant and other occasions for iron, iron removal operations.The magnetic field distribution characteristics of this series devices is good for the recovery effect of fine powder, make the recovery rate of the magnetic minerals greatly improve .

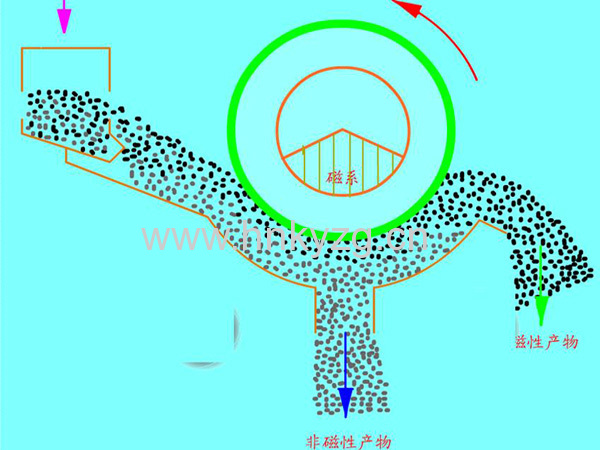

Operating principle:

magnetic separator is based on the different magnetic properties between the ore minerals to separate either valuable minerals from non-magnetic gangue or magnetic contaminants or other valuable minerals from the nonmagnetic values. After the ore pulp flow into the chute, the ore particles enter the ore feeding area separately under the influence of the water flowing from the jet pipe. The ferromagnetic particles get together and become magnetic floc on the magnetic field there. After that, the magnetic floc move forwards to the magnetic pole and stick to the rolling cylinder. As the magnetic floc and the cylinder rotate together, the magnetic pole rolls alternately, so the gangue and nonmagnetic particles will be agitated, and fall off to be discarged with the pulp.

Application field of CTB iron ore magnetic separator

The wet drum magnetic separator is ideally used to separate ferrous particles from non ferrous particles. Magnetic Separator is designated for wet magnetic separating of material with granularity below 3mm, such as magnetite, pyrrhotine, roasted ore and washingtonite. It can also be used for deironing of coal, nonmetal materials, building materials, etc

Main technical parameters

Model | Dia.of shell(mm) | Length of shell(mm) | Rotary speed of cylinder(r/min) | Feeding size(mm) | Capacity(t/h) | Power(kw) |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

Company profile

Henan Kuangyan Industrial Heavy Mahinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder,vibrating screen;

Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations

.jpg)