| Product Name | Best Price Supplier High Quality for Sale Unpolished (Black) Medical Super Elastic (Nickel Titanium Alloy) Nitinol Guide Wire | ||||||

| Standard | ASTM F 2063-05 | ||||||

| Material | Nickel titanium alloy | ||||||

| Size (mm) | Length | Width | Thickness | Diameter | ID | OD | Coating Thickness |

| L | N/A | N/A | 3 | N/A | N/A | N/A | |

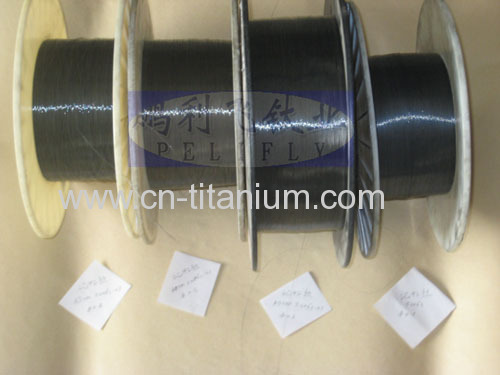

| Surface Treatment | Unpolished (black) or polished bright | ||||||

| Rolling Technology (H/C) | N/A | ||||||

| MTC | MTC EN 10204 3.1 | ||||||

| Payment Method | L/C, T/T, PayPal, Western Union, Escrow | ||||||

| Trade Term | FOB, CIF, CFR | ||||||

| Packing | Standard wooden case or plastic packing material (depending on product dimension) | ||||||

| Port | Tianjin, Shanghai | ||||||

| Lead Time | 7-30 days | ||||||

| Production Capacity | 1000 kg | ||||||

| County of Origin | P.R. China | ||||||

| Service Area | Asia, North America, South America, Europe, Africa, and Oceania. | ||||||

| Feature | Super elastic | ||||||

| Chemical Composition | Nickel . . . . . . . . . . . . . . . . . . . 54.5 to 57.0 (Reference) Carbon . . . . . . . . . . . . . . . . . . < 0.050 (500 ppm maximum) Cobalt . . . . . . . . . . . . . . . . . . . < 0.050 (500 ppm maximum) Copper . . . . . . . . . . . . . . . . . . < 0.010 (100 ppm maximum) Chromium . . . . . . . . . . . . . . . . < 0.010 (100 ppm maximum) Hydrogen . . . . . . . . . . . . . . . . < 0.005 (50 ppm maximum) Iron . . . . . . . . . . . . . . . . . . . . . < 0.050 (500 ppm maximum) Niobium . . . . . . . . . . . . . . . . . < 0.025 (250 ppm maximum) Nitrogen plus Oxygen . . . . . . < 0.050 (500 ppm maximum) Any Single Trace Element . . . . < 0.1 Total Trace Elements . . . . . . . . < 0.25 Titanium . . . . . . . . . . . . . . . . . Balance | ||||||

| Advantages | 1. Due to the high product quality and the amount of available products, other companies in this industry purchase from us as steady supply source. 2. Low purchasing cost for repetitive orders in the long-run as our performance/price ratio is higher. 3. Timely delivery to different areas around the world. 4. Excellent customer service policies on repair/exchange/refund. 5. Serving both domestic and overseas customers with various requirements for 10 years. | ||||||

nitinol shape memory wire

Sizes:0.1mm-7.0mm

Aplication : Widely used in the dental arch wire, interventional stent wire, surgical sutures, medical guide wire,

eyeglass frames, mobile phone antennas and bra stand.

Advantages: small size, light weight, low power, a very high strength-to-weight ratio, precise control, AC or DC activation, long life, and direct linear action. These features let you create whole categories of amazing new devices that would be difficult or impossible to do with anything else.

When in use a muscle wire can be stretched up to 8 percent of its length and still recover. However, this can only be done a few times until it breaks or stops returning to its original length. Its life cycle can be extended dramatically if it is stretched to between 3 to 5 percent of its overall length. Within this range it will go through the stretching and return cycle millions of times

Alloy | Chemical composition | Af (Fully annealed) | Min. elongation to failure [%] | Max. Residual elongation after 6% strain [%] | Main Applications | Specifications | |

Superelastic Ni-Ti alloy | TiNi-SS | Ti-50.8at% | -5°C ± 5°C. | 10 | 0.1 | Eyeglass Frames, Cellular Phone Antennae, Bra Underwire | Q/XB1516.2 Q/XB1516.2 |

TN3 TNC | TiNiVAl TiNiCr | -40°C ~50°C | 10 | 0.1 | |||

Body temperature Ni-Ti alloy | TiNi-YY | Ti-50.7at%Ni | Functional Af=33 ± 3 | 15 | 0.1 | Implantable devices,Bone staples Vascular Stents | ASTM 2063 |

Ti-Ni-01 | 55.6~55.8 wt%Ni | 20 - 40 | 15 | 0.1 | Guide wires, Stents Orthodontic Arches | Q/XB1516.1 | |

High temperature Ni-Ti alloy | Ti-Ni-02 | 54.8~55.5wt%Ni | 45 - 95 | 10 | 0.1 | Implantable active devices, Surgical tools, Thermostats Coffeepots | Q/XB1516.1 |

TiNiCu | TiNiCu | As-Ms ≤ 5 | 10 | 0.1 | |||

Tolerance

Diameter | 0.1~0.2 | >0.2~0.5 | >0.5~1.0 | >1.0~2.0 | >2.0~4.0 | >4.0~7.0 |

Tolerance | -0.025 | -0.04 | -0.06 | -0.08 | -0.10 | -0.14 |

6. physical property

Density (g/cm^3) | 6.45 |

Melting point (°C ) | 1240-1310 |

Specific heat capacity( kJ/(kg·°C) | 0.46 |

Coefficient of thermal conductivity (W·m-1·K-1) |

10 |

Resistivity (10-6 Ω·m) | 80 |

Expansion coefficient (10-6 Ω·K-1 ) | 10.4 |

Elastic modulus (GPa) | 40-80 |

HV | 180-200 (low-temperature metallography) 200-350 (high-temperature metallography) |

Tensile strength (MPa) | 700-1100 |

Yield strength | 50-200 (low-temperature metallography) 100-600 (high-temperature metallography) |

Elongation δ % | 20-60 |

phase transition temperature (Af / °C) | -10-100 |

Recovery response variable % | 8, 6, 2 ,<0.5 |

Utmost service temperature (°C ) | Af +60, 250 |

Maximum recovery stress (Mpa) | 680 |