Machine introduction

Hongji Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (800-1350℃ calcination) in a continuous process. Materials produced using rotary kilns include:

Cement

Lime

Refractories

Metakaolin

Titanium dioxide

Alumina

Vermiculite

Iron ore pellets

They are also used for roasting a wide variety of sulfide ores prior to metal extraction.

Hongji lime kiln is used to produce quicklime through the calcination of limestone (calcium carbonate). The chemical equation for this reaction is

CaCO3 + heat → CaO + CO2

This reaction takes place at 900 °C (at which temperature the partial pressure of CO2 is 1 atmosphere), but a temperature around 1000 °C (at which temperature the partial pressure of CO2 is 3.8 atmospheres) is usually used to make the reaction proceed quickly. Excessive temperature is avoided because it produces unreactive, "dead-burned" lime.

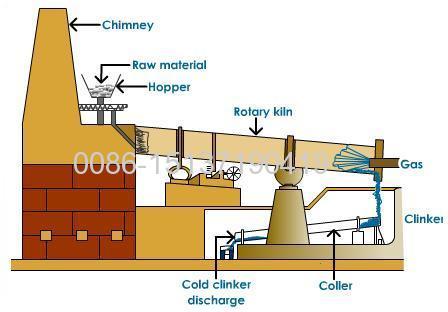

Working principle:

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal.

Structure

The basic components of a rotary kiln are the shell, the refractory lining, support tyres and rollers, drive gear and internal heat exchangers.

Machine packing and delivery

Machine woking

FRQ

About us

We Henan Hongji Mine Machinery Co., Ltd. is a professional mining machinery manufacture with ISO, CE Certificate, specialized in produce and develop various kinds mining machines for over 40 years, we are professional in:

- Stone crushing production line 5-500tph

- Sand making production line 50-200tph

- Ferro & Non ferro beneficiation process line (Au, Cu, Mo, Pb, Zn, Mn, Fe, Mn, etc)

- Industrial drying equipments (For sand, gypsum, filter cake, peat, biomass, clay, fertilizer, bentonite, Kaolin)

- Powder grinding equipments 80-200 mesh ( limestone, cement clinker etc)

- Cement/ Lime/ LECA production line with rotary kiln

Honors and Certificates

Service

Pre-sale:

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and choose best machine.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site.

4. Provide equipment list,design drawing, construction drawing, equipment install drawing.

During-sale:

1.Depend on scene, draw design drawing , construction drawing, equipment install drawing. 2.Manufacturing products strictly on contract while customer constructing.

3.Testing ex-work, delivery, customer acceptance.

After-sale:

1.Provide engineer to wok site guiding install.

2.Test equipment after installation, training operators.

3.Visit work site regularly

Please do not hesitate to contact with us for more details!

Skype: kellyliu_1987

M.P. 0086-15137190419