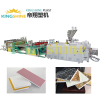

PVC Foam Board Production Line

Application of PVC Skinning Foam Board:

It is widely used in ambry, bath and all kinds of high-grade furniture board, building decoration materials, advertising engraving materials, and car, train, ship inner decoration materials.

Features of PVC Skinning Foam Board Production Line :

1. This line includes conical twin-screw extruder, vacuum shaping table, traction machine, cutting machines, foil machines, stacker.

2. Adopt PLC control and simple operation

3. Adopt the latest foreign technology, to optimize the design unit, with plasticizing uniform a small shear rate, high output, long life and so on .

4. The cutting machine is equipped with PLC control system which helps to set length and provide accurate automatic cutting.

5. All electric parts (breaker/motor/relay /Inverter and so on) is Siemens/Schneider/Omron.

Technical Parameters of this Plastic Foam Board Making Machine:

| Description | Parameters |

Material | PVC with rice husk |

Product Size | 1220mm width, 3-20mm thickness |

Production line speed | 0.5-1m/min |

Max.output | 380kg/h |

Overall Dimensions (LXWXH) | 20X3.5X3M |

Weight (Approx) | 10T |

Total install power | 320KW |

Actual energy consumption Power | 250kw |

Technology and service:

1. Seller supply full set of technical document, cutter and other full document (write in English) for the extrusion machine.

2. Seller supply training for buyer's staff until buyer can produce the eligible production independently.

3. Seller is responsible for installing, testing, adjusting and debugging the machines in buyer's factory.

4. Buyer should pay the expense for our engineers including for our engineer including round- way tickets, inland traffic, lodging and boarding fee when the machine is installed, tested and maintained.

5. Seller will go to install machines after the machine is arrived at buyer and buyer will have prepared all conditions (including power, water, compress air, tools and materials for producing pipe, etc) for installing and testing these machines. Buyer should pay 60USD/day.

6. When installing, people of both sides cooperate well and carefully, buyer supplies convenient working condition, any problem, should discuss peacefully and kindly.

7. Buyer supply proper working tools, equipments and other conditions.

8. The expense including the accommodation and materials of the trial-run the machine for testing and other expenses(electric, water, air and worker) will be on seller's account, if the buyer or their representatives do the inspection of the machines before shipment.

9. Guarantee period: 14 months after shipment (the date of B/L)