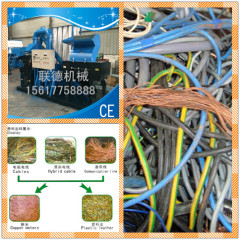

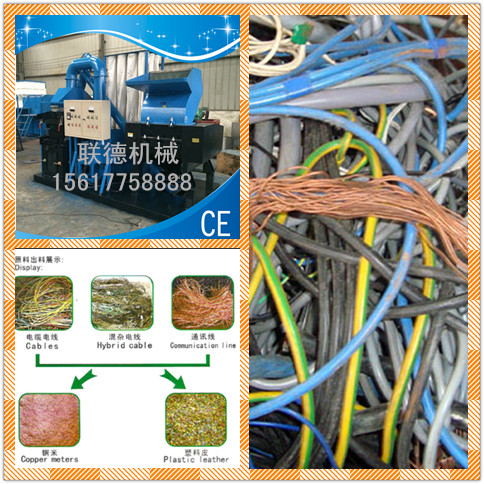

wire and cable recycling machinery equipment can be used to separate the copper and plastic material.copper wire recycling machine belongs to a kind of environmental protection machinery equipment.

scope of application and function:used for kinds of auto electrical wire,motorcycle wire. Storage battery bike wire. A television wire, washing machine and Refrigerator wire, Air conditioning and other household appliances wire,Telecommunications wire,Computer wire and so on.

Automatic grinding,Feeding,Aspiration,Separation. Only one workman can operate the machine.advanced dust collection device and dry separation make the finished product that is separated out can be directly sold to the market.

Special Features:

1.Especially suitable for shredding all kinds of waste computer hard disk and waste hard plastics.

2.Low rotation rate,low noise and large moment of torsion.

3.Using electrical control security design to ensure the safety of operators.

4.Special designed cutter with high strength and long service life.

5.Can be customized according to customer's special requests.

6.High capacity and stable performance.

Woring principle of waste copper wire recycling machine:

When directly put into the machine,used cable is cut into granules first,during this process,copper and plastic is separated but mixed together, then the granules are sent to vibration device for separation,through wind blow and vibration,the copper and

plastic are separated, then pure copper comes out from one side and pure plastic comes out from the other side, we collect the separated pure copper and plastic at last!

control system:

1: starting cabinet;

2: electric motor thermal protection device;

3: delay starting protection function;

4: vibration automatic control;

5: wind frequency conversion device control;

6: crusher cooling cycle.