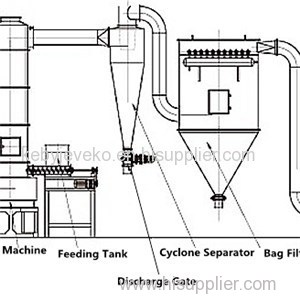

XSG Series Spin Flash DryerDescription:XSG rotating flash dryer is equipped with various advanced devices and components. A variety of feeding devices are adopted to make the feeding sustained and steady, which could avoid material accumulation and blocking the feeding inlet. Hot air enters from the bottom of the drying tower, which means the material crushing area is with high temperature. In order to prevent materials from adhering on the walls or going bad, a special cooling system is installed. Working life of the transmission device can be prolonged by the adoption of special barometric seal device and bearing cooling system. The mixing and grinding device at the bottom of the drying tower strongly grinds, blows and rotate the materials. The one-stop processes of grinding, drying and screening effectively prevent pollution and wastage. This equipment is with characteristics of strong mass and heat transportation ability, large production capacity, momentary dry, and is widely applied to process food materials, such as soy protein, gelatinous cornstarch, wheat starch, etc. Principle:Hot air enters the stirring and grinding drying cabinet in a appropriate speed from the bottom of the dryer, in which raw materials are granulated after being strongly ground, blown and rotated. The ability of mass and heat transportation is increased. Wet material clumps are ground by a stirrer at the bottom of the equipment, and the smashed small particles will be blown up and be further dried by the spinning hot wind . The air and the material particles spin and interact, and the inertia of solid particles is larger than that of the air, so that the relative velocity between the air and the particles is large. The transportation of heat and mass is then strengthened, which makes the equipment high-yield.Technical Parameters:ModelBarrel Diameter (mm)Dimension of Main Machine

(mm)Main Power

(kw)Air Treatment Capacity

(m3/h)Evaporation Capacity

(kg/h)Covering Area

(mm2)XSG-2200250*28005--9300-80010--203500*2500XSG-3300400*33008--15600-150020--503800*2700XSG-4400500*350010--17.51250-250025--704000*3000XSG-6600700*420020--292500-500040--2004250*3250XSG-8800900*460024--353000-800060--6004500*3500XSG-1010001100*500040--625000-12500100--10004750*3750XSG-1212001300*520050--8910000-20000150--13005000*4000XSG-1414001500*540060--10514000-27000200--16005250*4250XSG-1616001700*600070--10518700-36000250--20005500*4500XSG-1818001960*800085--12019500-42000300--30008000*7000Flow Chart:

Home >

Electronic & Electrical

>

Spin Flash Dryer Product Product Product

Spin Flash Dryer Product Product Product

Trade on HiSupplier, Worry Free Guarantee

•Trading safety, secure your money, lower the risk, protect both buyers and suppliers

•HiSupplier is a Chinese multinational company in U.S, it helps to coordination and order landing.

- Product Details

- Company Profile

- Product Reviews

Related Products

Didn't find what you're looking for?

Post Buying Lead or

contact our customer service specialist for help!

.jpg)