-- Thanks to the "integrated measuring ring", which is the center of our innovation, the required distance of axial drive-up of bearings with taper bore during installation can be done precisely without dial gauge or other instrument of any kind. -- The very same ADP hydraulic nut can be used for mounting as well as dismounting. An unique feature that is not rivaled by any current patented designs available on the market. -- Less time required to disassemble the hydraulic nut if sealing rings are to be replaced. -- Basically, there is no need to double-check internal clearance of bearing upon installation because of the measuring capability of the hydraulic nut itself. This comes in handy especially for those readily-sealed bearings where no internal clearance check is possible.

Dimensions Axial displacement max Piston area Mass Desination Max. force at 100Mpa(1000bar) G d1 d2 d3 B B1 B2 mm mm mm2 kg - KN M50×1.5 50.5 85 114 38 4 36 5 2900 2.7 HMV10E 290 M55×2 55.5 90 120 38 4 36 5 3150 2.75 HMV11E 315 M60×2 60.5 95 125 38 5 36 5 3300 2.8 HMV12E 330 M65×2 65.5 101 130 38 5 36 5 3600 3 HMV13E 360 M70×2 70.5 107 135 38 5 36 5 3800 3.2 HMV14E 380 M75×2 75.5 112 140 38 5 36 5 4000 3.4 HMV15E 400 M80×2 80.5 117 146 38 5 36 5 4200 3.7 HMV16E 420 M85×2 85.5 122 150 38 5 36 5 4400 3.75 HMV17E 440 M90×2 90.5 127 156 38 5 36 5 4700 4 HMV18E 470 M95×2 95.5 133 162 38 5 36 5 4900 4.3 HMV19E 490 M100×2 100.5 138 166 38 6 36 5 5100 4.4 HMV20E 510 M105×2 105.5 143 172 38 6 36 5 5300 4.65 HMV21E 530 M110×2 110.5 149 178 38 6 36 5 5600 4.95 HMV22E 560 M115×2 115.5 154 182 38 6 36 5 5800 5 HMV23E 580 M120×2 120.5 159 188 38 6 36 5 6000 5.25 HMV24E 600 M125×2 125.5 164 192 38 6 36 5 6200 5.35 HMV25E 620 M130×2 130.5 170 198 38 6 36 5 6400 5.65 HMV26E 640 M135×2 135.5 175 204 38 6 36 5 6600 5.9 HMV27E 660 M140×2 140.5 180 208 38 7 36 5 6800 6 HMV28E 680 M145×2 145.5 186 214 39 7 37 5 7300 6.5 HMV29E 730 M150×2 150.5 191 220 39 7 37 5 7500 6.6 HMV30E 750 M155×3 155.5 198 226 39 7 37 5 8100 6.95 HMV31E 810 M160×3 160.5 204 232 40 7 38 6 8600 7.6 HMV32E 860 M165×3 165.5 209 238 40 7 38 6 8900 7.9 HMV33E 890 M170×3 170.5 215 244 41 7 39 6 9400 8.4 HMV34E 940 M180×3 180.5 227 256 41 7 39 6 10300 9.15 HMV36E 1030 M190×3 191 239 270 42 8 40 7 11500 10.5 HMV38E 1150 M200×3 201 251 282 43 8 41 8 12500 11.5 HMV40E 1250 Tr205×4 207 256 288 43 8 41 8 12800 12 HMV41E 1280 Tr210×4 212 262 294 44 8 42 9 13400 12.5 HMV42E 1340 Tr215×4 217 267 300 44 8 42 9 13700 13 HMV43E 1370 Tr220×4 222 273 306 44 8 42 9 14400 13.5 HMV44E 1440 Tr225×4 227 280 312 45 8 43 9 15200 14.5 HMV45E 1520 Tr230×4 232 285 318 45 8 43 9 15500 14.5 HMV46E 1550 Tr235×4 237 291 326 46 8 44 10 16200 16 HMV47E 1620 Tr240×4 242 296 330 46 9 44 10 16500 16 HMV48E 1650 Tr250×4 252 307 342 46 9 44 10 17600 17.5 HMV50E 1760 Tr260×4 262 319 356 47 9 45 11 18800 19 HMV52E 1880 Tr270×4 272 330 368 48 9 46 12 19800 20.5 HMV54E 1980 Tr280×4 282 341 380 49 9 47 12 21100 22 HMV56E 2110 Tr290×4 292 353 390 49 9 47 13 22400 22.5 HMV58E 2240 Tr300×4 302 364 404 51 10 49 14 23600 25.5 HMV60E 2360 Tr310×5 312 375 416 52 10 50 14 24900 27 HMV62E 2490 Tr320×5 322 387 428 53 10 51 14 26300 29.5 HMV64E 2630 Tr330×5 332 397 438 53 10 51 14 27000 30 HMV66E 2700 Tr340×5 342 408 450 54 10 52 14 28400 31.5 HMV68E 2840 Tr345×5 347 414 456 54 10 52 14 29400 32.5 HMV69E 2940 Tr350×5 352 420 464 56 10 54 14 29900 35 HMV68E 2990 Tr360×5 362 431 472 56 10 54 15 31300 35.5 HMV72E 3130 Tr365×5 367 436 482 57 11 55 15 31700 38.5 HMV73E 3170 Tr370×5 372 442 486 57 11 55 16 32800 39 HMV74E 3280 Tr380×5 382 452 498 58 11 56 16 33500 40.5 HMV76E 3350 Tr385×5 387 459 504 58 11 56 16 34700 41 HMV77E 3470 Tr400×5 402 475 522 60 11 58 17 36700 45.5 HMV80E 3670 Tr410×5 412 486 534 61 11 59 17 38300 48 HMV82E 3830 Tr420×5 422 498 546 61 11 59 17 40000 50 HMV84E 4000 Tr430×5 432 508 556 62 11 60 17 40800 52.5 HMV86E 4080 Tr450×5 452 530 580 64 12 62 17 44100 57.5 HMV90E 4410 Tr460×5 462 541 590 64 12 62 17 45100 60 HMV92E 4510 Tr470×5 472 552 602 65 12 63 18 46900 62 HMV94E 4690 Tr480×5 482 563 612 65 12 63 19 48600 63 HMV96E 4860 Tr490×5 492 573 624 66 12 64 19 49500 66 HMV98E 4950 Tr500×5 502 585 636 67 12 65 19 51500 70 HMV100E 5150

Hydraulic nuts M50×1.5 - Tr500×5

-- Other than the above, general features/functions are identical or superior to current market offerings.

Design Principle

The hydraulic nut are designed for a maximum oil pressure of 100 MPa (1000 bar or 14500 psi).Their stoke is power enough that the rolling bearings or other parts can be mounted in a single operation.

The bore G in the annular body is available with a metric fine thread, a trapezoidal thread or an inch thread. They are suitable for sleeve and shaft threadsof international standard.

ADP hydraulic nuts feature two oil supply connection holes with G 1/4 thread. Four handling holes are on the outside diameter of the annular body and two handling holes are on the side face for easier handling.

a) Design for accurate measurement of the piston travel:

To differentiate our add-on value from competitors, we focused on practicality and simplicity. Our idea was to build in a kind of " micrometer " onto the hydraulic nut so that there is no need for additional measuring instrument during installation. And this has been achieved by introducing a rotatable " measuring ring " on the outer rim of the piston via male and female threads. There are calibrations on the outer diameters of the annular body as well as the measuring ring. By adjusting and aligning calibrations on the opposite sides of annular body and measuring ring, the required axial drive-up can be achieved with ease within 0.015mm allowance of accuracy. The finer the thread pitch is the more precision it is going to give.

At the same time with the verification processes of our innovative ADP hydraulic nut with measuring ring, we've compared our product against competitors', which more or less adopting a design of an added-on dial gauge. During assembling of a hydraulic nut, it is very common that jerking takes place (especially when axial drive-up pressure exceeding 20 MPa) whenever there is a breakaway from overcoming static friction into sliding. Dial gauge with a nature of inaccuracy under jerking performs badly. Our product, on the contrary, proves to be influence-free from jerking.

b) Design for easy disassembly and maintenance:

In terms of maintenance, O-ring is the most consumed part and needs to be replaced anew once damaged. Our design of measuring ring provides an additional advantage over competitors'—jacking bolts do not intrude into annular body cavity. Intrusion by jacking bolts may create complication of compromising static sealing of the plug, which is important for constant high oil pressure application. With our design, there are three (3) jacking bolts equally spaced on the measuring ring. Upon disassembly for the replacement of O-ring these three jacking bolts are exactly the only tool and procedure need to be done, reliable and time-saving.

c) Flexible in both directions of installation:

Our measuring ring provides no interference in both directions during installation, i.e. the same hydraulic nut can be used for mounting and dismounting of withdrawal sleeve.

How it works

Example 1: Mounting a spherical roller bearing with adapter sleeve, 22320 K (see Step 1 to Step 5 by diagrammatic explanation). Theoretically, the axial drive-up for mounting it on a taper seating is 1.06 mm according to the calculation (the required max. radial internal clearancereduction is 0.06% of the nominal diameter of the bearing bore). In fact, due to the quality and the manufacturing allowances involved with shaft and adapter sleeve, there are variations in the total clearance before installation. And in practice, those variations can be eliminated by applying a pre-load pressure, which is 7.1 MPa (71 bar) more or less, in the hydraulic nut. After that, a further 0.92 mm in axial drive-up needs to be accomplished.

The thread pitch of the measuring ring is 1 mm. 0.92 mm in axial drive-up is converted into angular travel by the following simple equation:0.92÷1.00×360=331.2°≈330° As demonstrated by the following illustrations and steps, one can see how easily this can be done.

The example above mentioned is for the convenience diagrammatic explanation . In fact, for mounting spherical roller bearing 22320K with adapter sleeve H2320, two sliding surfaces, the initial preload is 8.7 MPa, a further 0.65 mm in axial drive-up needs to be accomplished . The thread pitch of the measuring ring is 1.5 mm. 0.65 mm in axial drive-up is converted into angular travel 155° . See the mounting data on Table 1.

Example 2, for mounting bearing 23164K with withdrawal sleeve AHX3164G which has two sliding surfaces, an ADP hydraulic nut HMV68E is used, the initial preload is 7.8 MPa, a further 1.85 mm in axial drive-up needs to be accomplished . The thread pitch of the measuring ring is 2 mm. 1.85 mm in axial drive-up is converted into angular travel 334°. This hydraulic nut can be used for extracting the sleeve in the same time. See the mounting data on Table 2.

Table 1 and Table 2 are our proposal which aim for the total reduction ofinternal clearance is 0.05% -0.055%of the nominal diameter of the bearing bore. (The variations depend on the section heightof the inner ring ofbearing design.)

Mounting Procedures

All the mounting data ofare listed on Table 1 and Table 2 which is very important for accurate mounting of spherical roller bearing with taper bore.It is very simple to use the data on the Tables:

-Depend on sleeve types, choose Table 1 or Table 2

-Select the sliding surface, single or double

-Find the preload pressure

-Choose the angular travel range

1-1Screw in the ADP hydraulic nut on the thread of the adapter sleeve and rotate the hydraulic nut with the help of a steel pin inserted on the outer rim of the annular body until the bearing is tightened by the hydraulic nut.

1-2Open the valve of the hydraulic pump.

1-3 Connect the high-pressure hose of hydraulic pump to the quick connecting nipple on the hydraulic nut. 1-4 Make sure again that the bearing is tightened against by the hydraulic nut.

1-5 Close the valve of the hydraulic pump to prevent the oil from back-flowing.

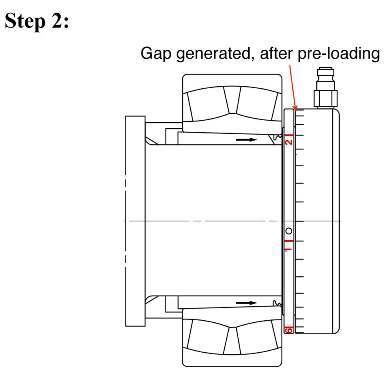

Pump the oil pressure up to 70 bar (7 Mpa). There will be a gap resulted from the axial movement of the piston when jacking up the oil pressure. It doesn't matter how big or small the gap is.

3-1Insert a Φ5 mm pin into the hole on the outer rim of the measuring ring and rotate it to tighten against the annular body.

3-2Mark one of the calibrations on the measuring ring as the reference starting point. In this example, index no.1 is specified.

3-3Locate a mark 330° away from the reference starting point in step 3-2 on the calibrations of the cylinder as the target mark. Aligning the reference starting point (index no.1) with the target mark will have the job done.

Continue to pump the oil to an appropriate incremental pressure. There will be a growing gap between measuring ring and annular body. Stop pumping and rotate the measuring ring to close the gap. Watch how far you need to go between the reference starting point (index no.1) and the target mark.

Repeat step 4 in graduation until alignment of the reference starting point and the target is reached.

Threads

ADP hydraulic nuts up to and including size 40 have metric ISO threads to tolerance 6H(ISO 965/III-1980)and the lager nuts from size 41 have metric ISO trapezoidal threads to tolerance 7H (ISO 2901-1977).

The mating thread on the shaft should made to the tolerance 6g (ISO 965/III-1980) for the small sizes, and tolerance 7e (ISO 2901/1977) for sizes with trapezoidal thread.

Material

The annular body of ADP hydraulic nuts up to and including size 64 are made ofhardenable steel and the pistons are made of bearing steel. From size 66 the annular bodys and pistons are made of Grade 2 construction steel.

Hydraulic-HMV-E SeriesHMV10E HMV11E HMV12E HMV13E HMV14E HMV15E HMV16E HMV17E HMV18E HMV19E HMV20E HMV21E HMV22E HMV23E HMV24E HMV25E HMV26E HMV27E HMV28E HMV29E HMV30E HMV31E HMV32E HMV33E HMV34E HMV36E HMV38E HMV40E HMV41E HMV42E HMV43E HMV44E HMV45E HMV46E HMV47E HMV48E HMV50E HMV52E HMV54E HMV56E HMV74E HMV58E HMV60E HMV62E HMV64E HMV66E HMV68E HMV69E HMV70E HMV72E HMV73E HMV76E HMV77E HMV80E HMV82E HMV84E HMV86E

Hydraulic-HMVC-E Series(inch dimensions)

| HMVC10E | HMVC11E | HMVC12E | HMVC13E | HMVC14E | HMVC15E | HMVC16E | HMVC17E | HMVC18E | HMVC19E |

| HMVC20E | HMVC21E | HMVC22E | HMVC23E | HMVC24E | HMVC25E | HMVC26E | HMVC27E | HMVC28E | HMVC29E |

| HMVC30E | HMVC31E | HMVC32E | HMVC33E | HMVC34E | HMVC36E | HMVC38E | HMVC40E | HMVC41E | HMVC42E |

| HMVC43E | HMVC44E | HMVC45E | HMVC46E | HMVC47E | HMVC48E | HMVC50E | HMVC52E | HMVC54E | HMVC56E |

| HMVC74E | HMVC58E | HMVC60E | HMVC62E | HMVC64E | HMVC66E | HMVC68E | HMVC69E | HMVC70E | HMVC72E |

| HMVC73E | HMVC76E | HMVC77E | HMVC80E | HMVC82E | HMVC84E | HMVC86E |

.gif)