Product Introduction:

Our high speed die cutting machine is not only the good one, but are the best in the world. In the ski distance of 200mm, our speed can reach 103 meters per minute with perfect stability. Even in the long ski distance we can reach 80 meters per minute. Our machine pressure is 37 tons and each time for starting up the machine, it always remaind stable at 37 tons, which make us the best in the world. Pressure determine the accuracy and the stability.

This product is suitable for all kinds of adhesive label. Die cutting,slitting , rewinding can be in one process. It have automatic tension controller system for unwinding and rewinding, Automatic inflating air for air shafts, Optional Start and stop by foot. This machine has automatic meter count, number count, length preset, automatic-stop when up to length preset functions. The unwinding is controlled by the two photoelectric eyes. The whole machine structure is compact, fast and with high efficiency. Operation is easy and steadily.

Standard Configurations:

Feeding sheet machine | 1 set |

Whirlpool type tension blower | 1 set |

Die-cutting upper/lower plate | 1 set |

Converse hot stamping device | 1 set |

Quadratic tracking-mark electric eye | 1 set |

Horizontal rewind | 1 set |

Carborundum roller | 1 set |

Touch screen(operating panel) | 1 set |

clamping wheel | 1 set |

Upper and lower stamping plate | 1 set |

Horizontal rewind induction box | 1 set |

Main Technical Parameters: (We can customise 280mm to 550mm)

Model | RBJ-280B | RBJ-330B | RBJ-330C | RBJ-370B |

Maximum die cutting speed | 420 times/min. | 420 times/min. | 420 times/min. | 420 times/min. |

Die cutting length | 260mm(left station) 330mm(right station) | 260mm(left station) 330mm(right station) | 260mm(left station) 330mm(right station) | 260mm(left station) 480mm(right station) |

Max hot stamping speed | 92m/minute | 92m/minute | 92m/minute | 92m/minute |

Max paper width | 280mm | 330mm | 330mm | 370mm |

Max Unwind diameter | 650mm | 650mm | 650mm | 650mm |

Max rewind diameter | 650mm | 650mm | 650mm | 650mm |

Dimension | 4800x1250x1650mm | 5300x1300x1700mm | 5700x1400x1800mm | 5300x1300x1750mm |

Main motor power | 4KW | 7.5KW | 7.5KW | 7.5KW |

Gross power | 12KW | 15KW | 15KW | 15KW |

Machine weight | 4.4T | 4.8T | 5T | 5.5T |

Applicable blade width | 7mm-23mm | 7mm-23mm | 7mm-23mm | 7mm-23mm |

Voltage | 3 phase 380V/32A | 3 phase 380V/32A | 3 phase 380V/32A | 3 phase 380V/32A |

Die cutting accuracy | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

Applicable material: roll fed material | <=350g | <=350g | <=350g | <=350g |

Main Advantages:

1: Adopt leaning type cutting theory and scissor type contact theory to make the machine structure to be high speed die cutting machine

2: All in one main machine frame.

3: Even if in the big ski distance,the cutting speed can reache 80 meters per minute.

4: In the 200mm ski distance,machine maximum speed can reach 103meters per minute with perfect stability.

5: When the machine cuts the Avery PET with the 0.023mm width substrate,the pressure is stable perfectly.

6: Just use the ordinary steel blade,which cost efficient.

7: Germany mechatronics

8: The machine is equipped with 2000 meters rewind and unwind.

9: Because the scientific design of leaning type,the machine possess perfect pressure and durability.And the use life is 20 years at least.

10: We can offer 5 years warranty for the stability of pressure.

11: When cuts the 0.3mm width PET, the cutting length of blade can reach 4.5 meter. And the speed can reach 25000 times per hour.

12: Whatever track mark or not,the cutting speed is the same.The maximum speed is 25000 times per hour. For example,in the ski distance of 200mm, whatever track mark or not, the minimum speed is 19000 times per hour.

13: Drive mode is alternating current dynamo which is punching type creating the instant maximum cutting dynamics.

Additional Configuration:

Our Services:

FAQ

1.Q: Are you a factory or trading company?

A:We are a factory and manufacturer.

2.Q: Where is your factory located? How can I visit there?

A:Our factory is located in Shenzhen City, Guangdong Province, China. You can land in Shenzhen airport directly. welcome to visit us!

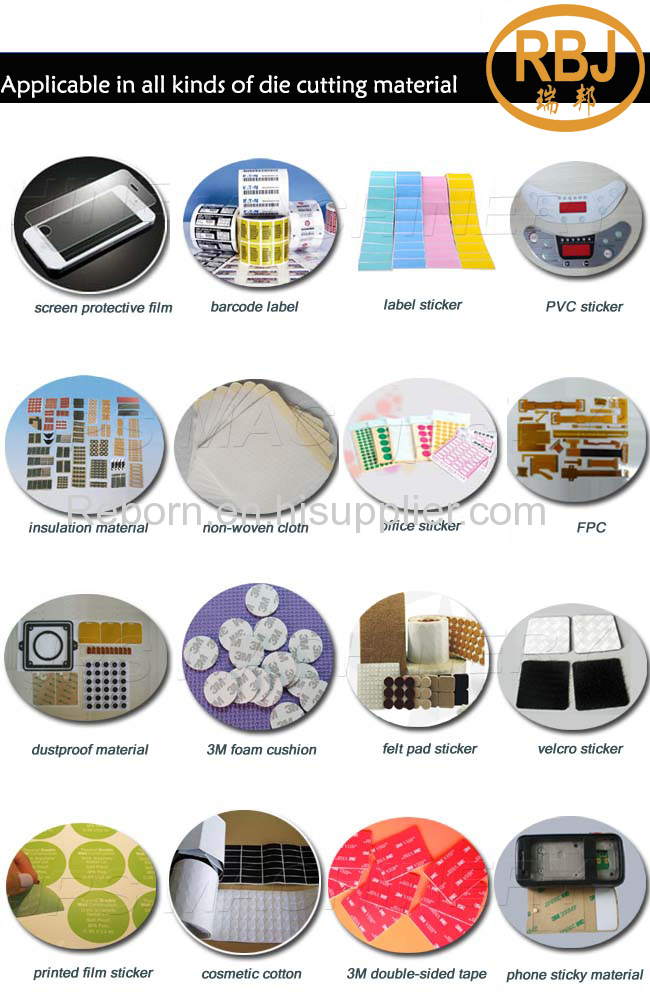

3.Q: Which industries are widely used in of your machine?

A: Those are mainly used in forming of three industries of adhesives products, electronics, and new energy power battery. Examples of protective film, cutting backlight products, adhesive products, mobile phone accessories, insulation film, garment accessories, automotive adhesives tapes etc.

4.Q: Could you send samples?

A: We are honored to receive your samples for die-Cutting Test.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority.Reborn always attaches great importance to quality controlling from the very beginning to the very end. Our factory has gained BV, Intertek, SGS authentication.

Patent Certificates: