Product Description

This 10 ton 300mm punch press for solar water heater equipment, used for punch the holes on galvanized outer tank and flanging the 0.5mm inner tank tube hole and punch other small hole like inlet & outlet hole, electric heater hole, magnesium rod hole, etc.

Details:

1. Steel plate welded c frame body, heat treatment, produced by cnc

boring and milling center, high rigidity and precission

2. Wet type pneumatic clutch with safety solenoid valve, lower noise

and longer service life.

3. Best quality gears, bushes, cylinders, link rods and ball screw

ensure the high performance, high reliability and longer service life.

4. Hydraulic overload protected system is standard equipped. The

press will stop with oil pressure release if overload to protect the

press and the die. It is easy to reset to normal status

5. PLC control, Omron or Panasonic brand, high quality with global

warranty.

6. Double hands control buttons, touch screen control panel, cam

controller with encoder.

7. Slide adjust motor is equipped on the back of the slide. This

position is better to protect the motor and the press is more compact

in this way. The slide is motorized adjusted with digital displayer.

8. Center auto grease lubrication system is standard equipped and

the lubrication frequency can be setted with the touchscreen. In the

meanwhile, manual thin oil lubrication system is equipped too

Packaging & Shipping

Packing:

nude packing usually;

wood case for foaming machine, mold, cnc punch press, etc.

by sea(machinery, big qty accessories for production);

by express(small accessories);

by air(emergency stuff).

100% in advance for small order;

30% in advance, balance before delivery/BL copy for large order;

T/T, LC, Western Union, Paypal all available.

Shipping:

Payment Terms:

Delivery Time: 7-30 working days.(depends on the goods and qty)

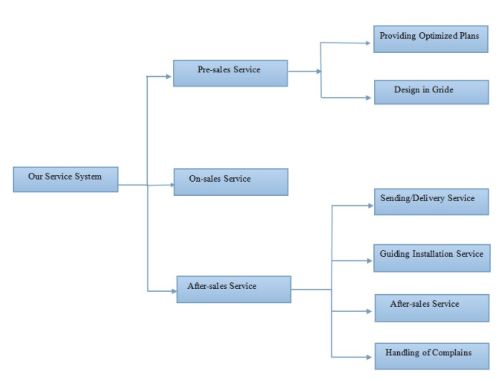

Our Services

1.Your inquiry will be replied in 24 hours;

2.Well-trained and experienced;

3.All your private information will be protected.

Certifications

CUSTOMER VISIT

Our Service

Quality and Service Assurance:

1.we have Q & C department in our factory and our engineer have much experience and can design the suitable machine for our clients.

2.our machine can produce the nice production, can guarantee good quality.the production is confirm to the national standard even the international standard

3.the products should not have scratch and the flatness

Technical R & D Department: design teams for different kind of production line.

package:

1.As to the roll forming machine's package, it should be nude.

2.we'll protect the machine well before shipment, to prevent machines from rusting and damage.

Repairs:

Warranty: 1 year since the date of B / L on

Installation and Commissioning:. We will send professional engineers to buyers' country for installation and commissioning Buyer pays each engineer 100USD / Day besides the round-tickets, room and board.

OUR TEAM

DURMA SUCCESSFUL CASE

DURMA OFFICE

Packing & Delivery

RFQ

Payment Terms:

T/T, L/C at sight are acceptable by us.

Guarantee period:

Our product quality guarantee period is 13 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.