Copany Profiles:

Invitech is a professional manufacturer of precision metal stamping and metal insert molding. Our core technology team specializes in precision progressive die stamping and metal insert molding for more than 30 years.

Our company is located in Zhejiang Province southeast of China, 2 hours drive from Shanghai and 30 minutes drive from Hangzhou. We have hundreds of precision punching machines, injection machines and automation equipment.

We implement 5S management, TPM equipment management and pass IATF16949 certification. With an excellent quality management system, we have won the trust of the global customers and become a strategic partner of PHILIPS and OSRAM for more than 20 years

We are committed to providing one stop solution including precision metal stamping, deep drawing and metal insert molding to our top customers in a wide range of industries around the world. We will provide you with comprehensive consulting services and customized development according to your needs. We look forward to further cooperation with you.

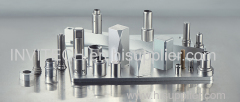

Deep drawing process:

1. deep drawing in multi-station transfer mold

Through multi-station transfer mold, we produce deep drawing parts of various non-ferrous metal materials with uniform wall thickness and bright surface. It is more suitable for small batch customization because of the convenience for molds replacement.

2. Deep drawing in high precision progressive die

We use progressive die to finish deep drawing, punching, rotary cutting, tapping, side punching, necking, flaring, and blanking in one mold.