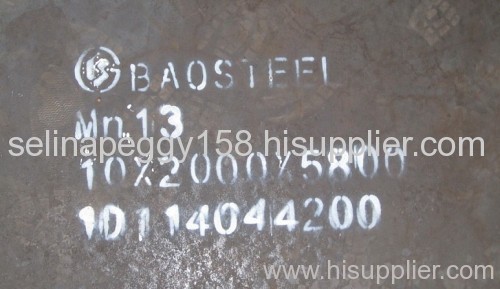

High manganese steel plates

High manganese plates are fully austenitic ,quench annealed, non magnetic

work hardening steel with exceptionally high level of wear resistance

when subject to work –hardening by shock or high impact pressure in service.

The main characteristics

Severe wear on the surface has a work –hardening effect on the austenitic structure

of this steel which leads to an increase in hardness from 200HB up to in service hardness of at least 600 Brinell.

Cutting

plasma or laser cutting

Forming

bending and rolling are easy-to be performed cold only

Forming:

Forming can be carried out without difficulty, as the plate in the supplied condition is ductile. To avoid cracking, edges which have been work hardened by shearing should have a 2 to 3mm chamfer ground along the edge to be formed. If possible, forming should be carried out in one operation in order to avoid work hardening.

Forming can be carried out without difficulty, as the plate in the supplied condition is ductile. To avoid cracking, edges which have been work hardened by shearing should have a 2 to 3mm chamfer ground along the edge to be formed. If possible, forming should be carried out in one operation in order to avoid work hardening.

Drilling:

High manganese steel is difficult to drill due to the 11 to 14% manganese content and will work harden very quickly. Heavy duty, very rigid machinery is required using either armour piercing drills in 8% cobalt high speed steel, or preferably, use special drills with replaceable carbide inserts. Avoid centre punching or allowing the drill to rub on the surface without the feed being engaged, as this has the effect of work hardening.

High manganese steel is difficult to drill due to the 11 to 14% manganese content and will work harden very quickly. Heavy duty, very rigid machinery is required using either armour piercing drills in 8% cobalt high speed steel, or preferably, use special drills with replaceable carbide inserts. Avoid centre punching or allowing the drill to rub on the surface without the feed being engaged, as this has the effect of work hardening.

Welding:

Welding should be carried out using E308Mo type austenitic stainless consumables. As a high manganese steel with high coefficient of thermal expansion and low thermal conductivity, welding should be carried out at a low thermal value. Prolonged time of the material in the temperature range of 300°C to 800°C can cause embrittlement due to carbide precipitation.

.jpg)

.jpg)