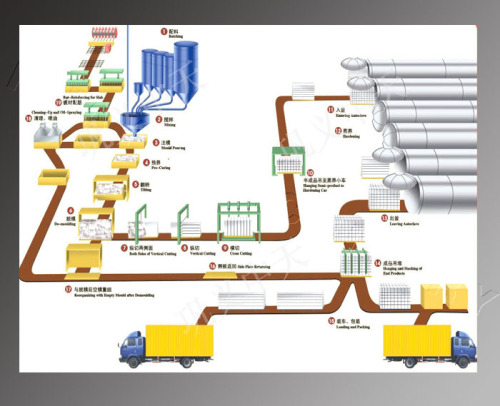

| Autoclaved aerated concrete ploduction line(AAC production line) --Process: | |||||||||||

|

Home >

Machinery & Industrial Supplies

>

Machinery & Equipment

>

Other Machinery & Equipment

>

AAC plant line

AAC plant line

| Payment Terms: | T/T,L/C |

|---|

Trade on HiSupplier, Worry Free Guarantee

•Trading safety, secure your money, lower the risk, protect both buyers and suppliers

•HiSupplier is a Chinese multinational company in U.S, it helps to coordination and order landing.

- Product Details

- Company Profile

- Product Reviews

Basic Info.

- Model No.: HUAYU

- Place of Origin: Shanghai

- Min.Order: 1 Set/Sets

- Means of Transport: Ocean, Air, Land

Supply Capacity

- Packing:wooden case

- Delivery Date: 30 days

Autoclaved Aerated Concrete(AAC) block and board have becomethe pillar industry in construction field. China has introduced AAC technologybefore 40 years, our company is the earliest manufacture and RD institute of Autoclaved Aerated Concrete (AAC) machinery, and our technologyhas reached the advanced level of Autoclaved Aerated Concrete (AAC)machine industry. The sales volume and comprehensive indexes of our AeratedConcrete (AAC) equipment are ahead of others in China. The aerated concrete(i.e. aeroconcrete) is characterized by the advantages of light weight, heatpreservation, sound isolation, high strength,processable property and so on,what's more, the raw materials of AAC are abundant. Especially,it can not only make use of industrial waste residue, improve environmentalpollution, and protect tillable field, but also create favorable social andeconomic benefits to take fly ash as the raw material of AACblock and board.Aerated concrete (i.e. aeroconcrete) is the perfect wall material to replace thetraditional solid clay brick. For many years, Autoclaved AeratedConcrete (AAC) has always accepted strong supports from the policiesabout reforming of wall material, tax policies and environment protectionpolicies. Aeroconcrete (AAC) block and board have become the important part ofnew-type construction materials, and possess bright development

Didn't find what you're looking for?

Post Buying Lead or

contact our customer service specialist for help!