1. The situation of organic waste gas

In the productive process of Evaporators and Condensers in air-conditioner factories, they need to consume a large amount of fin punching oil, a small part of it which attached to production and transport equipment are taken away, and after drying of the work pieces ,the most of the rest part will exhaust to the atmosphere and pollute the peripheral environment. But many companies can't find appropriate way to solve this problem, the surrounding villagers complain a lot.

2. Feasibility analysis

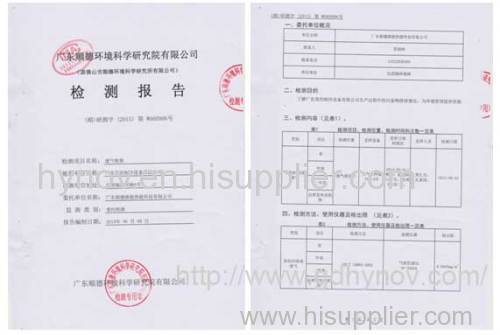

The Hynov company uses its patent technology (efficient and energy-saving Organic Waste-gas treatment equipment and system) to transform project. After overcoming many difficulties,we finnaly finished the transform project. The system's running is stable, and recycle large amount of fin punching oil from air every day. The system is both energy conservation and environmental protection. Every parameter of emitted gas can reach the test standard of Guangdong Shunde Environmental Science Research Institute Company.

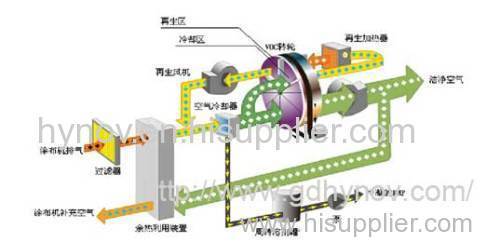

3. Working principle

A large amount of solid particulate can be removed from Organic Waste-gas after the filter. We use the heat recovery system and the air cooler to cool and recover 95% organic solvent. And then it enter voc wheel, where can exhaust 90% fresh air. The surplus 10% Waste gas will pass regeneration heater, then by circulation of the regeneration zoon and fan,the Organic Waste gas can be burnt completely to transform CO2 and water.

4. System structure

The device to recover organic solvent from waste gas mainly includes, molecular sieve condensed wheel, air cooler, air regeneration heater, fan device, Circulating Cooling Water Tower and so on.

5. Technical Specifications

(1)over 95% organic solvent can be recovered.

(2)the air exit have no smell, can meet the require of national emission standards

(3)can meet the require of Guangdong province organic matter emission standards

(4)the recovered solvent can be recycled.

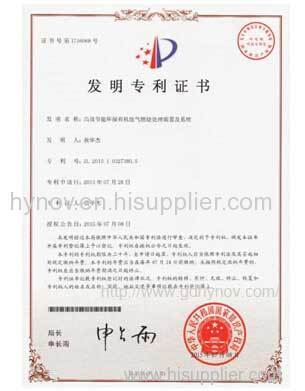

6. Patent of invention

7. The third party testing report

8. Project