1. Product introduction

The combustion-supporting system of natural gas is made for its energy-saving, and ensures full combustion; after heating high temperature air and push it into the Burning gun of the combustion-supporting system of natural gas, the natural gas can burn completely and quickly, which can save the consumption cost of burning. This system is made after many tests by using the waste heat hot-water system and gas-to-gas heat exchanger system according to the actual situation and needs of customers' factory. So the Energy-saving Transformation of natural gas also includes the transformation of hypoxia.

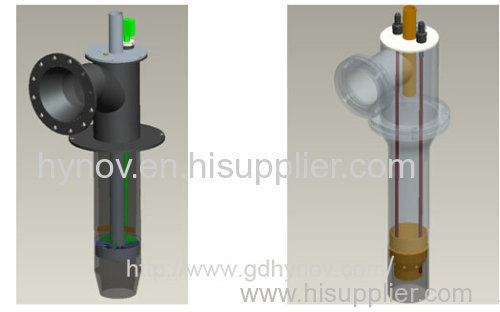

2. Efficient and Energy-saving Burning gun

3. Benefit analysis

When annealing furnace works, it will produce 500℃High temperature exhaust gas. We push it into the customized gas-to-gas heat exchanger, and use it to heat the Low-temperature Air, which the draught fan pulled into. Finally, we get the 300℃High temperature gas. Then, we push this gas into our natural gas Burning gun after transformation, which uses the scientific distribution and combustion support to enhance the mix of the natural gas and air, improve the combustion quality of natural gas, and get the best combustion value. In this way, we can get 10%-20% energy-saving effect of combustion support, and saving energy consumption and long-term operating cost for our customer

4. The Energy-saving Transformation system of combustion

5.Product Applications

The combustion-supporting Transformation technology has been used for ceramic industry, boiler combustion in industrial and mining enterprises, curing oven in production line; the combustion-supporting technology of organic waste gas recovery's combustion has been used for ink screen and iron printing factories.