China supply one step 1500A melamine paper impregnation line

Impregnation line is used for secondary processing of man-made board. It is suitable for man-made board processing industry.

To impregnate and dry surface paper, balance paper, wear-resistant paper; furniture décor paper, HPL surface & core papers for laminating, with melamine resin or its modified glue or urea resin.

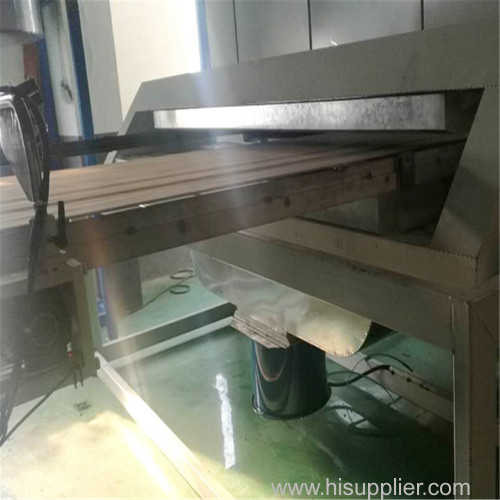

1,One step impregnation line

●Main processing as following:

Raw paper roller→unwinder→tracor→ prerwetting→penetration→impregnation→measurement→wipe→dryer→cooler→web aligner→tractor→cutter→conveyor→stacking lifter.

●Impregnated material: phenolic resin, melamine resin

●Main product: decorative paper,cement formwork paper, balance paper ,insulating paper

●Applicable products: veneering of furniture board, decorative paper of HPL plate, veneering of cement template, laminated flooring, CCL impregnated paper.

●Function and Feature

(1)The system use advanced impregnation technology,with high precision metering roller and anilox roller, it can precisely control the glue quantity, gluing uniform and continuous adjustable.

(2)The transmission roller and the heat fan are controlled by high efficiency and energy-saving inverter, Low energy consumption, stable synchronous speed and low breaking rate;

(3)Use RS422 and RS485 technology to realize man-machine interface(touch screen),PLC and communication control of inverter, instead of traditional panel control, greatly improved the digitization of whole machine, with good anti-jamming performance and ensure the stable of system.

(4)Industrial modular design, simple human - machine conversation,rich prompting information

(5)Coding technical is used on cutter system,high precision and good accuration.

(6)High precisionPID is used to control the temperatureof dryer.

(7)Online adjust the synchronization rate and system parameters.

(8)Searching and statistical production reports of day/month/year.