Submerged arc furnace main technical parameter

1 Transformer rated capacity 8000 KVA

2 Transformer primary voltage 35 KV

3 Transformer secondary rated voltage

4 Transformer secondary rated current 40.163 KA

5 Electrode diameter 780mm

6 Furnace hearth diameter 4740 mm

7 Furnace hearth depth 1800 mm

8 Furnace hearth diameter 6300 mm

9 Furnace shell height 3500mm

10 Electrode pole diameter 2100 mm

11 Taping hole quantity 2

12 smoke hood diameter 7400 mm

13 Electrode stroke 1200 mm

14 Electrode lifting speed 0.5

15 Electrode copper watt 5

2-8-2 Oil pipe net

2-9 Pneumatic system

2-10 Furnace inside water circulation

2-11 Insulation and standard part

2-12 Tapping system

2-12-1 calcium carbide pot

2-12-2 ladel car

2-12-3 tractor

2-12-4 shell track

Features of submerged arc furnace

1 Continous pouring and casting ingots

2 Counter flow cooling ingots

3 Bottom pouring and top casting

4 Manual adjusting pouring speed

5 Automatical additional charging

6 Automatical mold pallet

7 High efficiency , low power consumption

8 Heating mode : Electromagnetic heating

Equipment Description

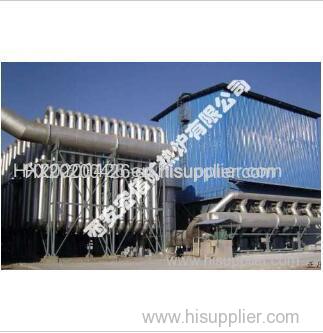

Submerged melting furnace, also known as electric arc furnace or resistance furnace. It is

mainly used for the reduction of smelting ores, carbon reductants and solvents etc. It is

mainly for production of ferrosilicon, ferromanganese, ferrochromium, tungsten iron, silicon

and manganese alloy and other ferroalloy, all above are important industrial raw materials

and calcium carbide and other chemical raw materials in metallurgical industry.

Contruction

Submerged arc furnace used for steelmaking consists of a refractory-lined vessel, usually water

cooled in large size, covered with a retractable roof, and through which one or more graphite

electrodes enter the furnace. The furnace is primarily split into three sections :

Furnace main body electrical equipment

1 High voltage cabinet and cable crane span structure

2 low voltage cabinet, front furnace operation platform, PLC cabinet

3 Power and control cable, lighting distribution box

4 Furnace transformer

Electric furnace main mechanical equipment

1 Furnace body rotation

Equipment list

Electric part

three phase transformer

High voltage cabinet

Construction

Submerged arc furnace used for steelmaking consists of a refractory lined vessel, usually water

cooled in large size, covered with a retractable roof, and through which one or more graphite

electrodes enter the furnace. The furnace is primarily split into three sections

Application of submerged arc furnace

Submerged arc furnace is using electricity as the fuel source, and utilizes the arc high

temperature produced by electrode and furance charge to heat and melts the furnace

charge.

Submerged arc furnace structure

the first layer is furance body

the second layer

Fume hood

Electrode holder

short net

copper tile

Electrode shell

unloading system

turning down machine

Supply list

1 Mechnical parts

Furnace body ( upper shell and lower shell )

Tilting mechanism

water cooled roof and water pipe

Roof lifting and rotating mechannism

Electrode arms and traveling mechanism

EBT platform

Rotation frame locking device

Feeding hopper (on the roof)

Electrode nippling station

Cooling water distributor

2 Electrical parts

Transformer 40 MVA

20KV high voltage system

Short network

Lower voltage system

PLC automation and HMI system

3 Auxiliary items

Hydraulic power pack

Compressed air device

Lubrication station

Water cooled door oxygen lance

oxygen carbon wall lance

Steel temperature and measuring thermometer

Submerged arc furnace structure

component

Furnace shell / roof / lining

large current system

water cooling system

Fume exhausting system

Dedusting system

Electrode shell

Electrode slipping system

Charging / discharging system

Electrode holder

Arc burner

Hydraulic system

Transformer