Hongxin Arc furnace company introduction

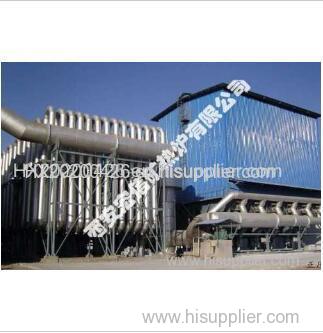

Xi'an Hong xin arc furnace company liminted specialized in developing, desgining ,

manufacturing, engineering installation and technical service of ferroalloy submerged

arc furnace, new type metallurgy equipment and gasp purification system. It has a registered

capital of 10 million Chinese Yuan and there are more than 150 staff in the company.

Hong xin company has its own manufacturing plant with the area covering around

10,000 M 2, equipped well by different kinds of prcessing equipment, which can meet the

requirements for making submerged arc furnace, gas purification system etc. meanwhile,

company has full ability of perform the turnkey porject.

Hong xin company has indepedent design and R& D capabilities , has established technical

cooperation relations with a number of research institutes and universities in succession and

emplyed several famous domestic experts as technical advice. We have our specialized persons

which is the member of group of expers of Iron Alloy Association in China.

Device components

Electric arc furnace body

High current system

Tilting furnace mechanism

Electrode lifting mechanism

Cover up rotating mechanism

Water-cooling system

Hydraulic system

High voltage system

Furnace introduction

Submerged melting furnace, is also known as electric arc furnace or resistance furnace,

it is mainly used for the reduction of smelting ores, carbon reductants and solvente etc.

It is mainly used for the reduction of smelting ores, carbon reductants and solvent etc.

It is mainly for production of ferrosilicon, ferromanganese, ferrochromium, tungsten iron,

silicon and manganese alloy and ohter ferroalloy, all above are important industrial raw

materials and calcium carbide and other chemical raw materials in matallurgical industry.

Furnace main boy electrical equipment

1 High voltage cabinet and cable crane span structure

2 Low voltage cabinet, front furnace operation platform, PLC cabinet

3 Power and control cable, lighting distribution box

4 Furance transformer

Component

Furance shell / roof / lining

Large current system

Water cooling system

Fume exhausting system

Dedusting system

Electrode shell

Electrode lifting system

Electrode holder

Arc burner

Hydraulic system

Transformer

Auxiliary equipment

Two beam overhead crane

suspended electric arc furnace

Electrode lifting machine

Stoking machine etc

Equipment supply list

Mechinical parts

Furnace body (upper shell and lower shell )

Tilting mechanism

Water cooled roof and water pipe

Roof lifting and rotating mechanism

Electrode nippling station

Cooling water distributor

Electrode arms and traveling mechanism

EBT platform

Rotation frame locking device

2 Electrical parts

Transformer

High voltage system

Short net

Lower voltage system

PLC automation and HMI system

3 Auxiliary items

Hydraulic power pack

compresed air device

Lubrication station

Water cooled door oxygen lance

Oxygen carbon wall lance

Steel temperature/ measuring themometer

Furnace Main Technical parameter

Transformer rated capacity

Transformer secondary rated voltage

Transformer secondary rated current

Electrode diameter

Furnace hearth diameter

Furnace hearth depth

Furnace shell diameter

furnace shell height

Electrode pole diameter

Tapping hole quantity

Smoke hood diameter

Electrode stroke

Electrode lifting speed

Electrode copper watt

Oil cylinder

Oil pipe net

Pneumatic system

Furnace inside water circulation

insulation and standard part

Tapping system

Calcium carbide pot

Ladle car

Tractor

Shell track

Circulation charging machine

Batching system

Batching bin

Electronic weighting hopper and barcket

Belt machine and barcket

Equipment list

Electric part

Three phase transformer

High voltage cabinet

low voltage control cabinet

furnace body

Furance shell

Water cooling smoke hood

smoke pipe

Tapping smoke evacuation system

Short net

copper tube

water cooling cable

water cooling compensator

copper tile

copper bar

Hanging and stainless steel bolt

Equipment component

Furnace shell / roof / lining

large current system

water cooling system

Fume exhasuting system

Dedusting system

Dlectrode shell

Electrode lifting system

Charging / discharging system

Electrode holder

Arc burner

Hydraulic system

Transformer

Mechnical parts

Furance body

Tilting mechanism

water cooled roof and water pipe

Roof lifting and rotating mechanism

Electrode arms and traveling mechanism

EBT platform

Rotation frame locking device

Feeding hopper ( on the roof )

Electrode nippling station

Cooling water distributor