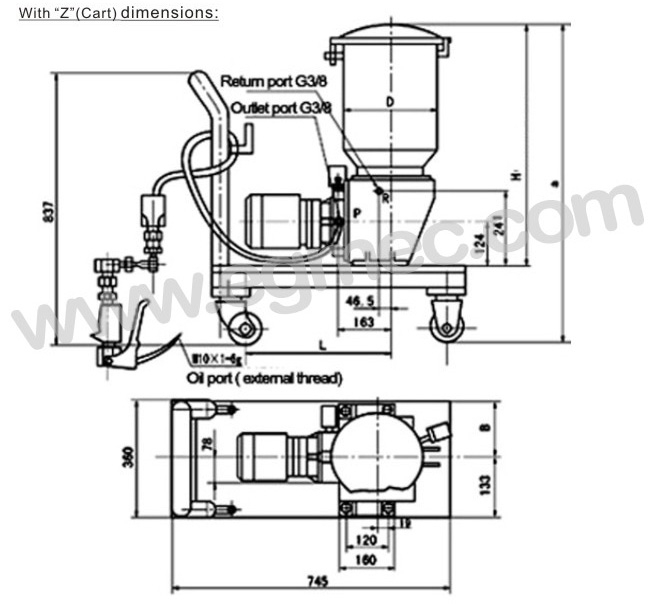

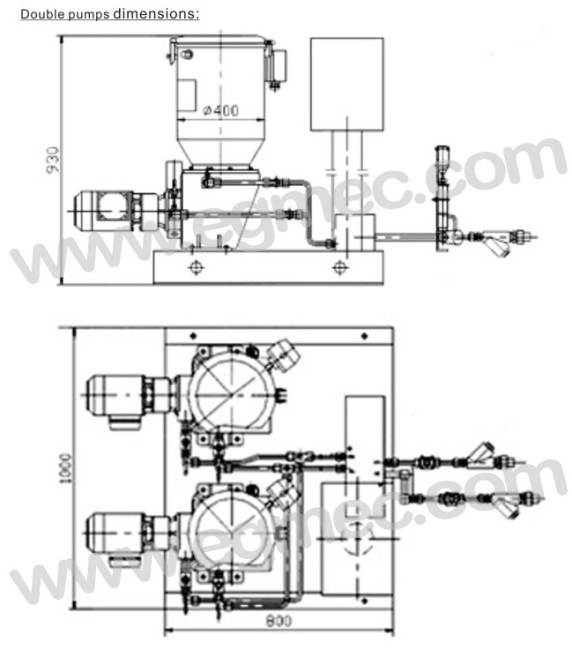

The series of DRB-P series high pressure single/double grease lubrication pump is used for lubrication of high frequency, length of pipes is large, dense single lubrication points, double dry thin oil lubrication system, as the supply of grease delivery device. Can also be equipped with mobile cart, hose, gun and cable composed of mobile electric lubrication pump for lubrication of low frequency, less lubrication points, to oil, it is not easy to single centralized lubricating equipment, grease for the lubrication of moving . The High Pressure Single/Double Grease Lubrication Pump is high-pressure lubrication pump for electric plunger, working pressure can be adjusted within the nominal pressure, a double overload protection and the automatic alarm device with oil, lubrication pump, if equipped with double electric control box lubrication system to achieve automatic control, and system implementation monitoring.

The working principle of DRB-P High Pressure Single/Double Grease Lubrication Pump:

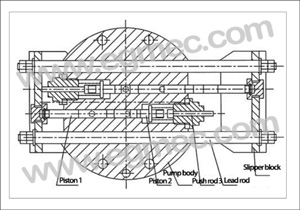

Drawing of inner construction

Work gear motor fixed in connection with a flange on the pump, the eccentric shaft driven by driving the fork for sliding reciprocating motion, and promote the spiral plate and scraping the oil pressure oil board clockwise (using the lubricant is no such institution), softened by stirring the grease evenly to the pump suction pressure around. Piston pump body two groups, each group working piston plug from 1 and 2 control piston, a piston when the piston to complete the work in the oil process, another group of Pistons put the grease in the work of the piston to the oil pressure mouth. As shown below, when the sliding fork to the left, the last group to complete suction piston, piston complete the next set of oil pressure to start a new cycle of work.

High Pressure Single/Double Grease Lubrication Pump

Then the next group of 1,2 to the left piston, the piston 2 in the spring force reaches the limit position close the exit, while the piston 1 to continue to the left, then formed between the piston 2 and a vacuum, the vacuum with the piston 1 the left is increasing, and slide the fork to the limit position of the piston movement to open an inlet of the grease from the oil inhalation, such as the lack of spring force, not be pushed to the limit position of the piston 2, 3, then putting the fork in the promotion of slippery force to the piston 2 under pressure to the limit position, while the group of 1,2,3 to the left piston, piston 1 to close the inlet, sucked the grease in the piston driven by a shift to the left, when the piston 2 the port is open, the piston 2 and 3, the movement will stop putting the piston 1 to the left, the grease out from the outlet port pressure, sliding contact with piston 1,2 fork has completed half of the movement to limit position cycle of work, again and again to cycle the piston alternately to two groups of lubricant oil from the mouth of pressure to send out, press out the grease pump device is connected through flanges on the filter for delivery to the system after filtration.

Then the next group of 1,2 to the left piston, the piston 2 in the spring force reaches the limit position close the exit, while the piston 1 to continue to the left, then formed between the piston 2 and a vacuum, the vacuum with the piston 1 the left is increasing, and slide the fork to the limit position of the piston movement to open an inlet of the grease from the oil inhalation, such as the lack of spring force, not be pushed to the limit position of the piston 2, 3, then putting the fork in the promotion of slippery force to the piston 2 under pressure to the limit position, while the group of 1,2,3 to the left piston, piston 1 to close the inlet, sucked the grease in the piston driven by a shift to the left, when the piston 2 the port is open, the piston 2 and 3, the movement will stop putting the piston 1 to the left, the grease out from the outlet port pressure, sliding contact with piston 1,2 fork has completed half of the movement to limit position cycle of work, again and again to cycle the piston alternately to two groups of lubricant oil from the mouth of pressure to send out, press out the grease pump device is connected through flanges on the filter for delivery to the system after filtration.

How to use High Pressure Single/Double Grease Lubrication Pump:

1.The using the essentials of the series of electric lubrication pump should be installed right in the environment, dust, small, easy adjustment, inspection, maintenance and washable and convenient place to make fat.

2.The series of electric lubrication pump should be arranged as the center of the system, shorten the length of pipes to maintain a minimum pressure drop, the pump can generate enough pressure to overcome the back pressure lubrication points.

3.The pump relief valve set pressure, 0 ~ 40MPa can be adjusted within the range, when in use must not exceed the nominal pressure of pump (40MPa).

4.At the pump outlet filter to filter regular cleaning to prevent clogging.

5.If a fault causes the series, so that the pressure of about 50MPa, the insurance piece that is broken, and then to identify the cause and eliminate the insurance into the new film.

6.To replenish the lubricant oil storage device must use DJB-H1.6 fill grease pump electric receptacles make fat from the port to join.

7.Inside the thin film of oil storage capacity indicator only applies to grease, oil medium is used, the capacity to be swapped into a float type indicator.

8.Beginning with the month of electric reducer plug from the exhaust hole to add the right amount of molybdenum disulfide grease 3 #, add one every four months later.

9.The series of electric lubrication pump for indoor installation type, outdoors or in harsh environment applications use, must take protective measures.

High Pressure Single/Double Grease Lubrication Pump DRB-P Series

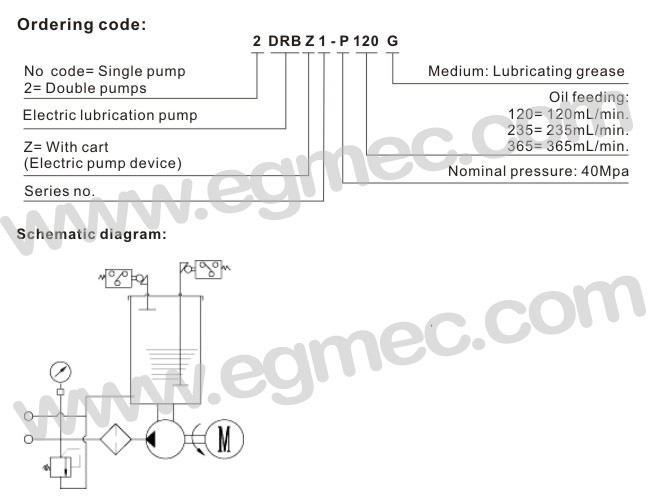

How to order High Pressure Single/Double Grease Lubrication Pump:

How to order High Pressure Single/Double Grease Lubrication Pump:

1.The Order operated electric lubrication pump device, which must be specified in the contract with the length of hose and cable length, not according to note the 10-meter cable, 3 m supply hose.

2.The series of electric lubrication pump with the following three forms of the standard electronic control box can be selected according to different control requirements order. 2.1 GDK01 type of non-monitoring electronic control box 2.2 GDK02 type has control electronic control box 2.3 GDK03 type has control, automatic control of electronic control box

3.The series of electric lubrication pump system work for the short time intervals, a family connection to work for a long time Please contract.

High Pressure Single/Double Grease Lubrication Pump accessories:

The insurance film 10 (deposited under the pump outlet side of the screw in) and sets of filters

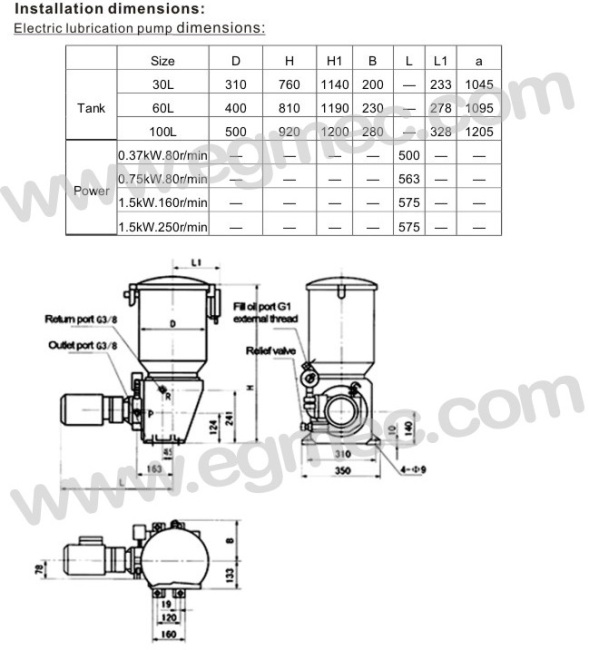

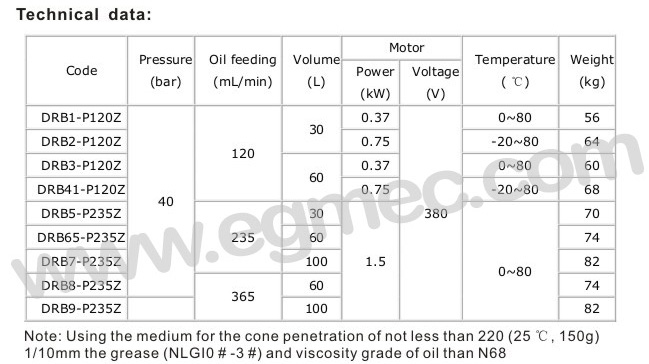

High Pressure Single/Double Grease Lubrication Pump technical data and installation dimensions as follow;