Sleeve type soft sealing plug valve acc.DIN

Plug valve structural features:

Sleeve type soft sealing plug valve acc.DIN is applicable to the cutting and connection of pipelines medium that are used in various industries such as petroleum.chemical industyy etc under nominal pressur of PN1.6-16MPa and working temperaturd of -29-180

Main structural features:

1\The produt thas reasonable structure,reliable sealing,excelent performance and beautiful appearance

Plug valve structural features:

Sleeve type soft sealing plug valve acc.DIN is applicable to the cutting and connection of pipelines medium that are used in various industries such as petroleum.chemical industyy etc under nominal pressur of PN1.6-16MPa and working temperaturd of -29-180

Main structural features:

1\The produt thas reasonable structure,reliable sealing,excelent performance and beautiful appearance

2\Its sealing is realized by the sealing face around sleeve it has unique 360 degree metal edge for protection and fixing of clipping cover.

3\There is no cavity in the valve for accumulation of medium.

4\Metal edge provides the funtion of self-cleaning when the plug is rotated applicable to the operation condition that is glutious and apttosmudge.

5\Its characteristic double-dircction flow makes installation and use more convenient.

6The materials of the parts and sizes of flanges can be reasonably configured according the actual operation condition of the requiements of the custiomers.so as to meet the variious needs of engineering.

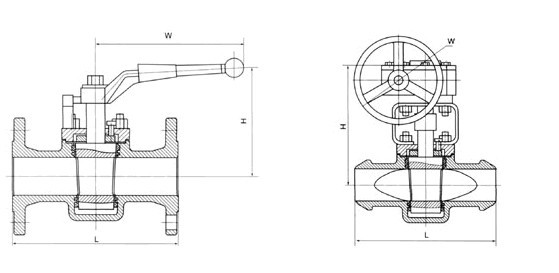

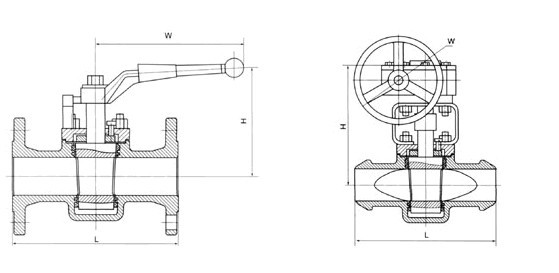

Plug valve drawing

Plug valve dimensionPlug valve drawing

Model | YDDX43-16 | ||||||||||||||

Pressure | PN16 | ||||||||||||||

size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

H | 150 | 155 | 160 | 180 | 190 | 200 | 220 | 230 | 380 | 460 | 520 | 580 | 620 | 680 | 740 |

W | 300 | 300 | 300 | 350 | 400 | 500 | 500 | 550 | 300 | 300 | 320 | 320 | 350 | 380 | 380 |

(kg)Weight | 9 | 10 | 11 | 13 | 14 | 19 | 23 | 27 | 43 | 62 | 75 | 155 | 222 | 390 | 580 |

model | YDDX43-25 | ||||||||||||||

pressure | PN25 | ||||||||||||||

size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

H | 150 | 155 | 160 | 180 | 190 | 200 | 220 | 230 | 380 | 460 | 520 | 580 | 620 | 680 | 740 |

W | 300 | 300 | 300 | 350 | 400 | 500 | 500 | 550 | 300 | 300 | 320 | 320 | 350 | 380 | 380 |

(kg)Weight | 10 | 11 | 13 | 15 | 17 | 22 | 31 | 55 | 77 | 88 | 190 | 190 | 235 | 399 | 630 |

Model | YDDX43-40 | ||||||||||||||

Pressure | PN40 | ||||||||||||||

Size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 |

W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

(kg)Weight | 12 | 14 | 18 | 21 | 24 | 29 | 33 | 39 | 75 | 103 | 146 | 251 | 337 | 521 | 720 |

Model | YDDX43-64 | ||||||||||||||

Pressure | PN64 | ||||||||||||||

size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 |

W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

(kg)Weight | 14 | 17 | 22 | 25 | 29 | 34 | 43 | 50 | 94 | 123 | 170 | 291 | 430 | 625 | 875 |