1plastic prototype materials thermal expansion, linear expansion coefficient than the metal in a lot; |

2 the general plastic prototype materials rigidity than metal of low magnitude; |

3 plastic materials mechanical properties in long time heating will be decreased; |

4 the general plastic materials at room temperature and below the yield strength under the strGeneral toy plastic raw material characteristics |

5 plastic materials on Notch damage is very sensitive; |

6 plastic materials mechanical properties are usually much lower than metal, but some composite material strength and specific modulus than metal, if product design reasonable, will be better able to play advantage; |

7 general reinforced plastic raw materials mechanical properties are anisotropic ess of stress for a long time, there will be a permanent deformation; |

Prouct name | Rapid prototype |

Competitive advantage | High precsion |

Prompt delivery | |

Reasonable price | |

Available Material | ABS,PP, POM, PC, PVC, Nylon, PMMA,Rubber,Brass, Iron,Carbon Steel,Aluminum |

CARFUL company | CARFUL company is an integrated, leading the team to provide professional, fast molding technology and innovation of the manufacturing process. Assemble CARFUL essence, innovation train of thought, explore new method, active enterprising, beyond the self, striving for the prototype industry pioneer |

1 .vacuum casting (silica gel model) prototype:

In a vacuum state, using the original model to produce silicone molds, then casting with the PU materials to clone a exactly same copy of the original model. Because the technology is fast, low-cost, so greatly reduces the costs, cycle and risk of the product development.

2.SLA laser rapid prototyping

Rapid prototyping technology is developed based on the modern CAD / CAM technology, laser technology, CNC technology, precision servo-drive technology and new materials technology .The materials used in forming, shaping principles and system characteristics are also different according to Different types of rapid prototyping systems. However, the basic principles are the same, that is "layered manufacturing, Layer-by-Layer," similar to the integral procedure in math. Figuratively speaking, rapid prototyping is like a "three-dimension printer".

-------------------------------------------------------------------

If you have project to do, what you should give us ?

1, file format:

3D:igs, prt , step, stp, sld.

2D:.dwg .cdr .pdf .ai, other pictures format.

2, we usually use the software

Pro-e (3D)

Solidworks (3D)

Rhinoceros() (3D)

3dmax (3D)

UG (3D)

Autocad (2D)

Photoshop (2D)

Coreldraw (2D)

Adobe Illustrator(2D)

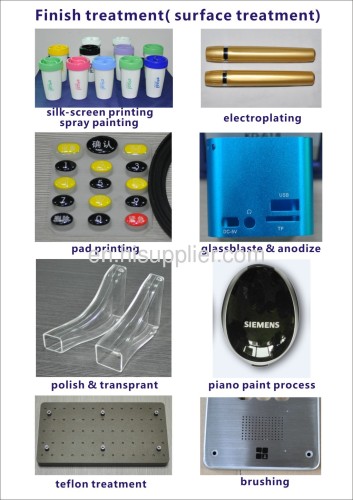

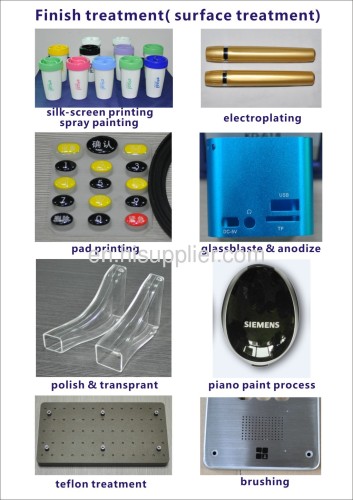

3, finish treatment(surface treatment)

If you need finish treatment(surface treatment),such as painting, screen printing, anodizing, glass blasted, pad printing, electroplating, oxygenation, brushing, etc. please give us the details as possible as you can. Such as the colors( with Panton numbers or CMYK&RGB numbers), the size of glass, the size and the location that you want to print, etc.

If you don`t know how to prepare them, please contact us for help.

Contact us:

Address:2F,Bldg.C,Fufang S&T Park, Fuyong Town, Baoan District, Shenzhen, Guangdong, China

Tel: +86-755-27150460

Fax: +86-755-27658255

M.P.:+86-15999640890

E-mail:gavin @carful.net

MSN:carful @live.com

Skype: gavin.cwh

Website:carful. com. cn; prototype-cn. com

-------------------------------------------------------------------

Gift for the business cooperation

CARFUL owned an another company that called "Carful Auto Accessories (Shenzhen) Co., Ltd.", we produce many excellent products such as Bluetooth car kit, universal hands-free mount,etc.(carful. cn).Every customer that cooperated with us in Rapid Prototyping and CNC processing project can get a gift from "Carful Auto Accessories (Shenzhen) Co., Ltd."

-------------------------------------------------------------------

customers and cooperation

We have lots of customers in Europe, America, Japan and South Korea and every parts of China. Such as Siemens, Philips, Nokia, Parrot,etc.

Meanwhile, CARFUL also cooperates with some domestic companies, associations, and foreign counterparts about academic exchange, sharing the technological achievements, to keep our technical ascendant, and established a good bridge for the both sides.

-------------------------------------------------------------------

faithful service and low price, keep secret for customers:

Realize your ideas; we assure your excellence with low cost!

Over 10 years` experience, perfect after-treatment handwork!

Carful Co., Ltd. was found in 2002, adhering to the spirit of "professional, high-quality, efficient, honest ", after recent years of exertion and innovation, we has developed into a professional and experienced company that include metal and plastic model making, rapid prototype making, small batch processing, Reverse Engineering,product and structure design, etc.

CARFUL will provide you with high quality guarantee, Efficient and competitive quotation, Your satisfaction is our greatest achievement!

Also we will keep secret for you strictly, we can sign contract separately for it.

We can accept the payment : 50 % upfront and 50% before shipment by sending photos for confirmation. So it will reduce the risk for your cooperation with us.

We can accept the payment : 50 % upfront and 50% before shipment by sending photos for confirmation. So it will reduce the risk for your cooperation with us.

-------------------------------------------------------------------

What can we do?

Service and application

Carful can provide you the rapid and satisfactory service in the field of product design, prototype making, batch processing. Meanwhile we can meet your requirement of different materials, processing technology and industries.

Product design

1. RE(reverse engineering). the experienced engineers uses precision laser measuring instrument to capture the design data of one product, then complete the design of products.

2. ID(Industry Design). Through market research and analysis, we will keep constantly communicating with customers, Screening, and improving, until we get a good idea that adapts to the market and the consumer.

3. MD(Mechanical Design). On the basis of full understand of the product`s functions, compliance to appearance design, reference to the size and form of various components, we determine the most reasonable structure design.

Prototype making

The classic ideas and reasonable structure, must be ultimately verified by prototype and model. Carful uses the required materials, with the process of CNC machining, laser rapid prototyping etc. and many technology such as grinding, polishing, fuel injection, screen printing, pad printing, laser engraving, sandblasting, electroplating, oxidation, drawing, the UV, relief etc. to complete the verification of the appearance, structure or function of your design.

1.Analyzing by processing methods, we can process the following prototypes and models :

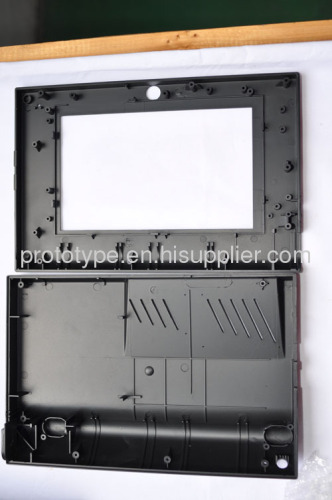

CNC plastic prototype: with the material of: ABS, acrylic, PP, PC, POM, nylon, wood, etc;

CNC metal prototype: with the material of:aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, steel, iron, etc;

Laser rapid prototyping: SLA, SLS, FDM, 3D printing ;

Rapid Tooling: rapid metal tooling, silicone molding, low-pressure pouring mould

Hand-carved making: with the material of: fatlute, foam, plaster, and so on.

2. Analyzed by application, we can process the following prototypes and models :

automobile components prototypes: automobile and motorcycle parts, car dashboard, shade and other parts;

medical devices prototypes: x-ray, blood dialysis device, monitor, foot care boxes

Industrial equipment prototypes: testing equipments, intelligent robots

Household appliances prototypes:such as color TV, air conditioning, electric fans, electric oven, monitors, kettles, coffee makers, electric fans, electric cooker, juicer, Blender, etc.

Digital telecom prototypes:such as mobile phones, telephones, fax machines, doorbell, cameras and others

Small batch processing

In industrial production, because of the different processes, costs, quantities, there are many parts that can`t use mass production by machines, which require a certain special technology to manufacture them with small batch. also they may need manual processing. We mainly use CNC to do the small batch processing.

1. Small batch processing of plastic parts , with the material: POM, ABS, transparent acrylic (commonly known as PMMA), PC;

2. Small batch processing of metal parts, with the material: aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, steel, iron, etc.