1. Specifications:

Mud Pump Liner with different Size

1). Material: Forged steel

2). High quality and long working time

3). Liners for mud pump parts

4). Our products can interchange with the mud pump produced by BOMCO, RG, HH and LS.

5). Small Minimum Order.

6). Quick delivery as we have some stocks in warehouse

7). Good service

2. API Std. Mud Pump Liner for Oil Drilling

A cylinder liner ( or cylinder sleeve) is a cylindrical part to be fitted into an engine block to form a cylinder. It is one of the most important functional parts to make up the interior of an engine. Our products after quenching technology for the surface and heat treating, the forged liner is with high intensity, strong tenacity and wearability. Main functions as belows:

(1) Formation of sliding surface

The cylinder liner, serving as the inner wall of a cylinder, forms a sliding surface for the piston rings while retaining the lubricant within. The most important function of cylinder liners is the excellent characteristic as sliding surface and these four necessary points.1) Less wear on the cylinder liner itself2) Less wear on the partner piston ring 3) Less consumption of lubricant

(2) Heat transfer

The cylinder liner receives combustion heat through the piston and piston rings and transmits the heat to the coolant.

(3) High temperature and high pressure

A cylinder wall in an engine is under high temperature and high pressure, with the piston and piston rings sliding at high speeds. In particular, since longer service life is required of engines, forging cylinder that have excellent wear-resistant properties are only used for cylinder parts.

We can provide the following liners: GARDNER DENVER: PZ-7, PZ-8, PZ-9, PZ-10, PZ-11;

IDECO: T–500, T–800, T–1000, T–1300, T–1600

3. Detailed description:

The Kingwell Mud pump liners used for mud pumps include premium Chromium Liners, Ceramic Liners, Chromium-plated Liners and Hardened Liners. Each liner combine the strength of a forged steel outer shell with the abrasionand corrosion resistance of a high chromium iron inner sleeve and honed to a mirror-like finish for smooth and even wear during the of the liner.

4. Parameters:

| EMSCO | |||

| F-350 | F-500 | F-650 | F-800 |

| F-1000 | FB-1300 | FB-1600 | |

| Gardner Denver | |||

| PAH | TEE | PZ-7 | PZ-8 |

| PZ-9 | PZ-10 | PZ-11 | |

| IDECO | |||

| T-500 | T-800 | T-1000 | T-1300 |

| T-1600 | |||

| National | |||

| 7-P-50 | 8-P-80 | 9-P-100 | 10-P-130 |

| 12-P-160 | JWS165L | ||

| Oilwell | |||

| A-350 | A-560 | A-600 | A-850 |

| A-1100 | A-1400 | A-1700 | |

| Others | |||

| 350-D | 350-DG | 500-DC | 700-HDL |

| 1000-HDL | MAS1000 | ||

5. Liners Kingwell are able to supply:

6. Other mud pump spare parts in Kingwell stock:

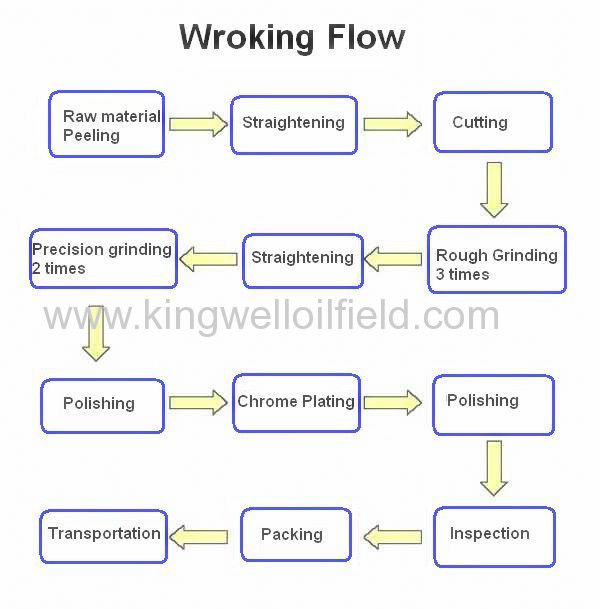

7. Working flow for Mud pump liner:

8.Why you choose Kingwell as your pump supplier:

1). Technical Support and Production Ability: Although we are one relatively new company, but we have the most professional engineers with tens of years experience in mud pump. And we have hundreds of highly skilled workers working on the pump parts and pump assembling with numerous advanced machines. Our production ability has been siteaudited by supervising inspectorate like France BV (Bureau Veritas), DNV(Det Norske Veritas) and SGS-CSTC(Standards Technical Services Co., Ltd.)

2). Quality Assurance: Ten professional inspectors performstrict quality inspection from the initial forgings, castings, other rawmaterials, each finished machined parts until the final assembling of the pump. Each part assembled on the pump will be well tested and highly qualified. Andfor each pump finished, it will be running tested in our test center for atleast 4 hours. Quality certificate, Inspection report and testing report will beattached when pump is delivered. 12 Months quality guarantee will be offered for each pump.

3). Competitive Price: We are one of the top pump manufacturers in China. We have the greatest advantages in price. We can not offer you the lowest price in China, but most competitive price but with very good quality.

4). Quick Delivery: Usually we will keep some pump model in stock so that we can make fast delivery for clients with urgent need. For pump we do not have in stock, we can also deliver with 40 days.

5). We can offer unitized pump package according to your different needs.

9. Kingwell inspection machine: