API G105 5-1/2"forging drill pipe

1. API 5D Specification of Drill Pipe:

1) Size: 2-3/8"-6-5/8"

2) Steel Grade: G105, S135

3) Supply Ability: 1000 sets per month

4) Machine Type: Drilling Equipment

5) Material: 4145H

6) Wall thickness:

7) Processing Type:Forging

8) Coating: Black painting / Vanish painting / 1PE/ 3PE/ FBE coated

Factory Directly!!

2. About Kingwell ceitificates:

3. Technical Parameter:

Nominal Spec. | Drill Pipe body | Tool joint | |||||||||||

Size (in) | W/T(ppf) | Grade | Up- set | O.D. (mm) | Wall (mm) | RSC Type | O.D. (mm) | I.D. (mm) | Bevel Dia. of Shoulder DF(mm) | Pin Tong (mm) | Box Tong(mm) | O.D. of Upset Neck(mm) | Torsion |

2-3/8 | 6.65 | E | EU | 60.32 | 7.11 | NC26 | 85.7 | 45.45 | 82.95 | 177.8 | 203.2 | 65.09 | 1.1 |

X | 85.7 | 45.45 | 82.95 | 177.8 | 203.2 | 65.09 | 0.87 | ||||||

G | 85.7 | 45.45 | 82.95 | 177.8 | 203.2 | 65.09 | 0.79 | ||||||

2-7/8 | 10.4 | E | EU | 73.02 | 9.19 | NC31 | 104.8 | 53.98 | 100.41 | 177.8 | 228.6 | 80.96 | 1.03 |

X | 104.8 | 50.8 | 100.41 | 177.8 | 228.6 | 80.96 | 0.9 | ||||||

G | 111.1 | 50.8 | 100.41 | 177.8 | 228.6 | 80.96 | 0.82 | ||||||

S | 41.28 | 100.41 | 177.8 | 228.6 | 80.96 | 0.82 | |||||||

3-1/2 | 13.3 | E | EU | 88.9 | 9.35 | NC38 | 120.7 | 68.26 | 116.28 | 203.2 | 266.7 | 98.43 | 0.98 |

X | 127 | 65.09 | 116.28 | 203.2 | 266.7 | 98.43 | 0.87 | ||||||

G | 127 | 61.91 | 116.28 | 203.2 | 266.7 | 98.43 | 0.86 | ||||||

S | 127 | 53.98 | 116.28 | 203.2 | 266.7 | 98.43 | 0.8 | ||||||

E | 11.4 | 127 | 65.09 | 116.28 | 203.2 | 266.7 | 98.43 | 0.97 | |||||

X | 127 | 61.91 | 116.28 | 203.2 | 266.7 | 98.43 | 0.83 | ||||||

G | 127 | 53.98 | 116.28 | 203.2 | 266.7 | 98.43 | 0.9 | ||||||

15.5 | S | NC40 | 139.7 | 57.15 | 127.4 | 177.8 | 254 | 98.43 | 0.87 | ||||

4 | 14 | E | IU | 101.6 | 8.38 | NC40 | 133.4 | 71.44 | 127.4 | 177.8 | 254 | 106.36 | 1.01 |

X | 133.4 | 68.26 | 127.4 | 177.8 | 254 | 106.36 | 0.86 | ||||||

G | 139.7 | 61.91 | 127.4 | 177.8 | 254 | 106.36 | 0.93 | ||||||

S | 139.7 | 50.8 | 127.4 | 177.8 | 254 | 106.36 | 0.87 | ||||||

E | EU | NC46 | 152.4 | 82.55 | 145.26 | 177.8 | 254 | 114.3 | 1.43 | ||||

X | 152.4 | 82.55 | 145.26 | 177.8 | 254 | 114.3 | 1.13 | ||||||

G | 152.4 | 82.55 | 145.26 | 177.8 | 254 | 114.3 | 1.02 | ||||||

S | 152.4 | 76.2 | 145.26 | 177.8 | 254 | 114.3 | 0.94 | ||||||

4.5 | 16.6 | E | IEU | 114.3 | 8.56 | NC46 | 158.8 | 82.55 | 145.26 | 177.8 | 254 | 119.06 | 1.09 |

X | 158.8 | 72.6 | 145.26 | 177.8 | 254 | 119.06 | 1.01 | ||||||

G | 158.8 | 76.2 | 145.26 | 177.8 | 254 | 119.06 | 0.91 | ||||||

S | 158.8 | 69.85 | 145.26 | 177.8 | 254 | 119.06 | 0.81 | ||||||

20 | E | 10.92 | 158.8 | 76.2 | 145.3 | 177.8 | 254 | 119.07 | 1.07 | ||||

X | 158.8 | 69.85 | 145.3 | 177.8 | 254 | 119.07 | 0.96 | ||||||

G | 158.8 | 63.5 | 145.3 | 177.8 | 254 | 119.07 | 0.96 | ||||||

S | 158.8 | 57.15 | 145.3 | 177.8 | 254 | 119.07 | 0.81 | ||||||

16.6 | E | EU | 8.56 | NC50 | 168.3 | 95.25 | 154 | 177.8 | 254 | 127 | 1.23 | ||

X | 168.3 | 95.25 | 154 | 177.8 | 254 | 127 | 0.97 | ||||||

G | 168.3 | 95.25 | 154 | 177.8 | 254 | 127 | 0.88 | ||||||

S | 168.3 | 88.9 | 154 | 177.8 | 254 | 127 | 0.81 | ||||||

20 | E | 10.92 | 168.3 | 92.08 | 154 | 177.8 | 254 | 127 | 1.07 | ||||

X | 168.3 | 88.9 | 154 | 177.8 | 254 | 127 | 0.96 | ||||||

G | 168.3 | 88.9 | 154 | 177.8 | 254 | 127 | 0.96 | ||||||

S | 168.3 | 76.2 | 154 | 177.8 | 254 | 127 | 0.81 | ||||||

5 | 19.5 | E | IEU | 127 | 9.19 | NC50 | 168.3 | 95.25 | 154 | 177.8 | 254 | 130.18 | 1.23 |

X | 168.3 | 88.9 | 154 | 177.8 | 254 | 130.18 | 0.97 | ||||||

G | 168.3 | 82.5 | 154 | 177.8 | 254 | 130.18 | 0.88 | ||||||

S | 168.3 | 69.85 | 154 | 177.8 | 254 | 130.18 | 0.81 | ||||||

25.6 | E | 12.7 | 168.3 | 88.9 | 154 | 177.8 | 254 | 130.18 | 1.02 | ||||

X | 168.3 | 76.2 | 154 | 177.8 | 254 | 130.18 | 0.96 | ||||||

G | 168.3 | 69.85 | 154 | 177.8 | 254 | 130.18 | 0.86 | ||||||

S | 0.87 | ||||||||||||

19.5 | E | 9.19 | 5-1/2FH | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 130.18 | 1.53 | |||

X | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 130.18 | 1.21 | ||||||

G | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 130.18 | 1.09 | ||||||

S | 184.2 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 0.98 | ||||||

25.6 | E | 12.7 | 177.8 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 1.21 | ||||

X | 177.8 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 0.95 | ||||||

G | 184.2 | 88.9 | 170.7 | 203.2 | 254 | 130.18 | 0.99 | ||||||

S | 184.2 | 82.55 | 170.7 | 203.2 | 254 | 130.18 | 0.83 | ||||||

5-1/2 | 21.9 | E | IEU | 139.7 | 9.17 | 177.8 | 101.6 | 170.7 | 203.2 | 254 | 144.46 | 1.11 | |

X | 177.8 | 95.25 | 170.7 | 203.2 | 254 | 144.46 | 0.98 | ||||||

G | 184.2 | 88.9 | 170.7 | 203.2 | 254 | 144.46 | 1.02 | ||||||

S | 190.5 | 76.2 | 180.2 | 203.2 | 254 | 144.46 | 0.96 | ||||||

24.7 | E | 10.54 | 177.8 | 101.6 | 170.7 | 203.2 | 254 | 144.46 | 0.99 | ||||

X | 184.2 | 88.9 | 170.7 | 203.2 | 254 | 144.46 | 1.01 | ||||||

G | 184.2 | 88.9 | 170.7 | 203.2 | 254 | 144.46 | 0.92 | ||||||

S | 190.5 | 76.2 | 180.2 | 203.2 | 254 | 144.46 | 0.86 | ||||||

6-5/8 | 25.2 | E | IEU | 168.3 | 8.38 | 6-5/8FH | 203.2 | 127 | 195.7 | 203.2 | 279.4 | 176.21 | 1.04 |

X | 203.2 | 127 | 195.7 | 203.2 | 279.4 | 176.21 | 0.82 | ||||||

G | 209.6 | 120.65 | 195.7 | 203.2 | 279.4 | 176.21 | 0.87 | ||||||

S | 215.9 | 107.95 | 195.7 | 203.2 | 279.4 | 176.21 | 0.86 | ||||||

27.7 | E | 9.19 | 203.2 | 127 | 195.7 | 203.2 | 279.4 | 176.21 | 0.96 | ||||

X | 209.6 | 120.65 | 195.7 | 203.2 | 279.4 | 176.21 | 0.89 | ||||||

G | 209.6 | 120.65 | 195.7 | 203.2 | 279.4 | 176.21 | 0.81 | ||||||

S | 215.9 | 107.95 | 195.7 | 203.2 | 279.4 | 176.21 | 0.81 | ||||||

4. Inspection and test equipment:

A well-established Quality System from Materials receipt to Products delivery ensures consistent quality at all levels of the activity. QMS Procedures & Measurements are tailored to establish high standards of Quality Assurance in the Operations. The Company maintains the 100% Traceability records as per API requirements & NACE MR 0175-2002 Standards and complies with all the legal, statutory and regulatory requirements.

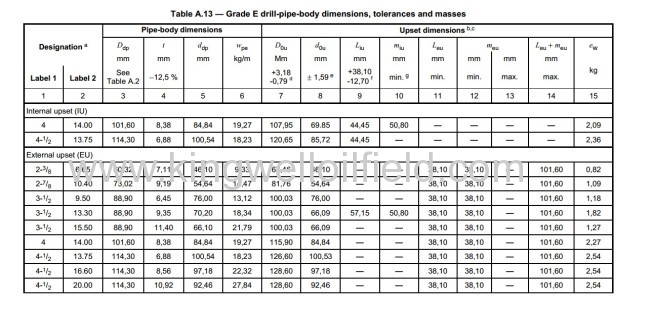

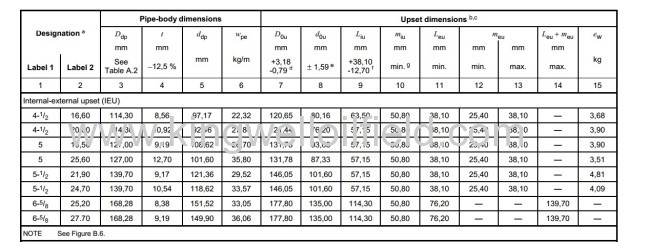

5. Some related technical paremete of drill pipe:

6. Drill Pipe Drawing:

7. Traceability:

Our mill follows the procedures for maintaining traceability to any applicable requirements has been documents. We could provide tracing welds t the lot to mechanical and test results.

8. Supply ability:

Now, we could ship drill pipe 1200 tons per month. With equiped with new machines, our manufacture capacity will reach 1800 tons per month.

9. Main Market:

South America / North America / Europe / Middle East / East-south Asia

10. MOQ: 10 TONS

11. Packing: In bundles or Loose

12. Contact:

1. Our working time: 8:00am~22:00pm (if urgent, please call our director: terry, Mobile: +86-18729329559)

2. All the inquiries will be replied within 24hours, so please feel to send us your inquiry.

3. When our skape is off line, please feel free to leave a message, and tell us the products you need, our model number, and your E-mail address.