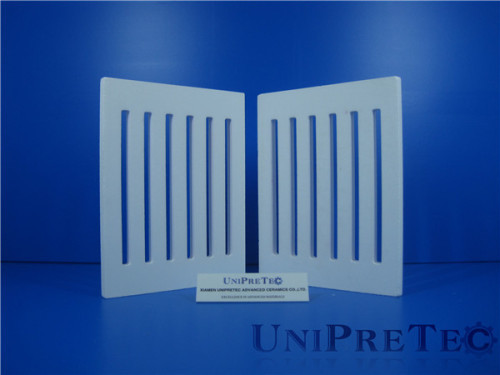

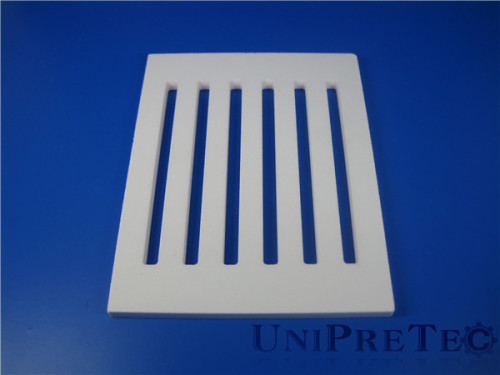

Refractory ceramic setter plates, high-tech products, are technical supporting parts for the high temperature furnace sintering. With the ceramic setter plates, the sintered products will be heated evenly. That will reduce energy consumption and accelerate sintering speed, improve yields.

1.Material:

85 Alumina Ceramic, 90 Alumina Ceramic, 95 Alumina Ceramic

2.Product Feture:

* High corrosion-resistance.

* High mechanical strength.

* Lower possibility of crack by thermal shock.

* Longer service time.

3.Properties of Alumina

Alumina has a high melting point, high hardness and high mechanical strength, although mechanical strength is reduced at temperatures above 1000°C. Due to the relatively large coefficient of thermal expansion, thermal shock resistance is reduced. Alumina is an electrically insulating material, with a high electrical resistivity, increasing with purity.Good chemical stability of alumina, leads to a high corrosion resistance. It is insoluble in water and only slightly soluble in strong acid and alkaline solution.

4.Different Refractory Ceramic Parts

* For electronic magnetic materials

* For positive electrode materials

* For magnetic materials kiln (push plate)

* For fine ceramics sintered

* For MIM stainless steel parts vacuum sintering

* Zirconia coating with (electronic) setter plate

* Cordierite - mullite kiln furniture

* Kiln components and refractory material iron steel

* High-alumina bearing boad

| Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

| Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

| Color | - | white | ivory | white | gray | white | white |

| Density | g/cm3 | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

| Flexural Strength @R.T. | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

| Compressive Strength @R.T. | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

| Thermal Conductivity @R.T. | W/(m*k) | 18-25 | 30 | 2.2 | 25 | 20 | 1.7 |

| Thermal shock resistance | Δ(℃) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

| Max. Working Temperature @R.T. | ℃ | 1500 | 1700 | 850 | 1200 | 960 | 800 |

| Volume Resistivity @R.T. | Ω*cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

| Dielectric Constant (1 MHz @R.T. ) | - | 9.5 | 9.8 | 26 | 8.2 | 4.08 | 6.02 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

5.About UniPreTec

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Boron Nitride, Machinable Glass Ceramic, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.