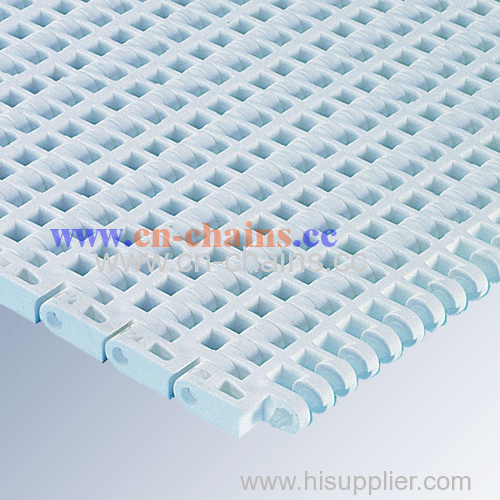

E20 Flush Grid conveyor belt with flight can convey the snack

dishwasher conveyor belt

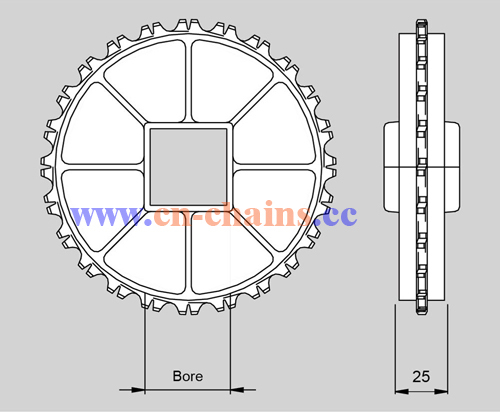

sprockets for E20

Belt date

Material of the belt | Material of the rod | Belt strength (kg/m) | Temperature range(°C) | Belt weight(kg/㎡ |

PP | PP | 1000 | 1 TO 104 | 4.2 |

PE | PE | 500 | -50 to 65 | 4.57 |

POM | PP | 2150 | 1 to 90 | 6.32 |

Sprockets data

No.of teeth | Diameter pitch | Bore for square shaft |

Hub width | |

mm | in | |||

8 | 52.5 | 20 | 0.75 | 24 |

16 | 102.5 | 40 | 1.50 | 40 |

24 | 153.5 | 40 60 | 1.50 | 40 |

Series E20 Flush Grid conveyor belt is ideal for applications in which drainage through the belt is required, avoiding any accumulation of particles on

its surface. Easy cleaning due to the possibility of applying water under pressure through the belt.

In the snacks industry the conveyor belts are an essential part of the production on a large scale. The product in bulk is conveyed at the same time that it is

processed, until the final product is obtained.So, if we talk about a potato chips line, the potatoes coming from land will be collected, washed, and carried to the

peeling-cutting machine by our plastic modular belts. Once they have been cut, we will convey them to a bath to regulate their starch. When they have

come out from the fryer we will transport them as they are salted, or some flavours are added, to carry them later on for their weighing and bagging. Likewise

we will convey the bags for their storage.Salt and oil are present in most of the processes of this industry, which is not tolerated by the conventional belt system.

Only the modular belts, injected with plastics more and more resistant to abrasion, provide a satisfactory result for abrasive environments.

In the snacks industry the conveyor belts are an essential part of the production on a large scale. The product in bulk is conveyed at the same time that it is

processed, until the final product is obtained.So, if we talk about a potato chips line, the potatoes coming from land will be collected, washed, and carried to

the peeling-cutting machine by our plastic modular belts. Once they have been cut, we will convey them to a bath to regulate their starch. When they have

come out from the fryer we will transport them as they are salted, or some flavours are added, to carry them later on for their weighing and bagging. Likewise

we will convey the bags for their storage.Salt and oil are present in most of the processes of this industry, which is not tolerated by the conventional belt system.

Only the modular belts, injected with plastics more and more resistant to abrasion, provide a satisfactory result for abrasive environments.

This Flush Grid plastic conveyor belt can be used in snack and vegetable industry because it was made of food grade material .

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.