Reconstituted Tobacco Sheet Processing Equipment Rolling 180kg/h

1. General Statement

Reconstituted Tobacco Sheet Production Line By Rolling is one complete group of equipment which makes full use of tobacco waste such as tobacco stems, powder and dust etc. produced in cigarette manufacturing process. It adopts special technical recipe and flow to finally remake the waste into tobacco Sheet filament.

This production line has the advantages of small investment, environment protection without pollution during manufacturing, reducing cigarette production cost greatly and producing great economic profit.

The production capability of it has specifications of 80kg/h, 180kg/h, 200kg/h, 400kg/h, 600kg/h, 800kg/h.

2. Working conditions:

2.1 Environmental temperature:10-40

2.2 Relative humidity: ≤85%

2.3 Altitude above sea level: ≤2000m

2.4 Power supply:3N-50Hz/TN-S 380V±38V 50Hz±1Hz

2.5 Inlet steam pressure of equipment: not less than 0.8Mpa

2.6 Inlet compressed air pressure of equipment: not less than 0.6Mpa

2.7 Inlet water pressure of equipment: not less than 0.2Mpa

2.8 Supplying material conditions: unpolluted and non-mildewed tobacco stem and powder, with moisture content not more than 16%, sand/ soil rate of tobacco stem not more than 2%, sand/ soil rate of tobacco powder not more than 3%, the length of tobacco stem not more than 20mm. Proportion rate of tobacco stem and powder material: tobacco stem from 30% to 60%, tobacco powder from 40% to 70%.When inlet material has been dried outside the line, water rate of the tobacco stem and powder entering grinder should be not more than 10% and its purity is not less than 98%.

2.9 Viscosity of CMC is not less than 600 centipoises, liquid mixture material should have no undissolved substance, materials larger than 60 mesh are not permitted to come into the liquid proportion device.

3. Main Technical Parameters

3.1 Production capacity:

Rate production capability is 80kg/h, 180kg/h, 200kg/h , 400 kg/h , 600 kg/h, 800kg/h (moisture content of product is taken as 13%)

3.2 Quality indexes of finished product (recon tobacco):

thickness of cut-recon: 0.12mm±0.01mm

length of cut-recon: 30mm-80mm

width of cut-recon: (0.8-1.0)mm±0.1mm

water content of cut-recon finished product: (13±1)%

whole cut-recon percentage: not less than 90%.

filling value:≥3.5cm³/g

Sheet grammage tensile strength, folding strength, tear strength, water resistance, softness should comply with the regulations of YC/T16.1-2002.

The total power consumption of the whole line:210KW

The dimension of factory building the whole line needed (optimized layout): L×W×H=70M×6M×6M

4. Technical flow and characteristics:

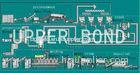

4.1 The technical flow chart

4.2 The main characteristics of Recon Production Line:

(1) Pre-treatment section adopts the working procedures of vibratory sieving, iron removing and pneumatic classification, to effectively eliminate the impurity of the raw material so as to raise the purity of the materials.

(2) The tobacco stem and powder adopts time-sharing drying on line and automatic classification storage. The stem and powder are proportioned automatically under the accurate control of screw electric scale with its error less than 2%. What’s more, it is convenient to adjust the proportion between the tobacco stem and powder. The drying of tobacco stem and power adopts the drying cylinder with dehydration capacity is more than 6%. After drying, the material has moisture of not more than 10%, which is easy to be grinded.

(3)The material pneumatic conveying system and grinded material pneumatic conveying system both adopt negative pressure operation, two-stage dust discharging, which improves the environment of workshop.

(4) Stem bin and powder bin both have been installed with material positioning sensor, which achieves an automatic start/stop of equipment through the signal interlocking.

(5) The measuring of liquid and solid material all adopt decrement electronic scales .It can control the accuracy of materials output through frequency conversion control. It can ensure the moisture accuracy ±2% after blending.

(6) It adopts advanced technology in stem defibration. The tensile strength of recon will raise over 100% after adding stem fiber. It raises greatly the valid utilization rate of the sheet which is ≥95%.

(7) The adoption of the second time crimping technology can raise the filling value of cut-recon. After the drying & crimping cylinder, there is a cooling device which cools down temperature of recon and helps shape-forming of the product quickly.

(8) It sets up moisture automatic control system. It can assure the moisture deviation ≤±1.5% after cutting. The moisture deviation of finished product is not more than ±1%.

(9) The control system is set up according to different control level; it is practical and advanced, easy for operation.

a. The control system has manual and auto operating modes. Manual operation is used in maintenance and on-site emergency treatment. Auto mode is used for normal production.

b. The system adopts PLC controller with high reliability and good brand low-pressure electrical components, and make the whole line operate automatically by start-stop in sequence control and by conditional interlocking. It gives real-time warning and indication for over current, lack of phase, short circuit etc. It is easy to maintain and repair. The system has high reliability.

c. The accuracy of measuring and blending of powder and liquid material can reach 99%. The blending ratio can be flexibly adjusted. The technology and production capacity have good adaptability.

d. As to those sections with high requirements for flow, speed, moisture and temperature, it adopts intelligent instruments, such as frequency control, temperature control apparatus, dynamic measuring electronic scales and moisture apparatus etc, it can be monitored and supervised locally, and it is also supervised by the upper-digit computer in concentration.

e. The upper-digit computer can achieve the concentrated supervision in order to facilitate the management on-line. It can generate production report forms showing material consumption and product statistics for data storage.

5. The system composition and functions

It consists of Raw material purifying system, Grinding and storing system, Powder and liquid material proportioning system, Rolling, drying & cutting system, Second time drying and crimping system, Electrical control system and General engineering system. There are options of fiber & glue proportioning system, long stem grinding system available for customers according to the raw material and special technical requests.

5.1 Raw material purifying system

5.1.1The system composition and functions

This system mainly consists of Quan