Casing Float Collar API Standard

Features

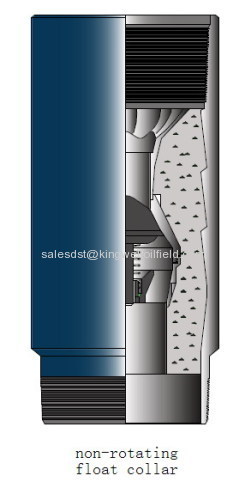

Float Shoe & Float Collar are used as kind of casing shoe or coupling to produce buoyancy. With advantages of high temperature resistance, good sealing feature and easy connection, Float Shoe & Float Collar can be used to replace guide shoe or casing shoe.

Float shoe and float collar can be used not only in unclassified technical casing, oil layer casing, but also in deep well, extra-deep well and special technology well

Parameter

| Specification(in) | O.D.(mm) | Total length(mm) | I.D.(mm) | Min.Dia.(mm) | Conn Type | Affordable pressure (Mpa) | |

| Float Collar | 5 | 141.3 | 500 | 110 | 50 | 5 BCSG | 35 |

| 5 1/2 | 153.67 | 530 | 112 | 55 | 5 1/2BCSG | 35 | |

| 7 | 194.46 | 586 | 162.5 | 77 | 7 BCSG | 35 | |

| 9 5/8 | 270 | 720 | 225 | 77 | 9 5/8 BCSG | 35 | |

| 13 3/8 | 365 | 720 | 319 | 77 | 133/8 BCSG | 35 | |

| 20 | 533.4 | 720 | 475 | 77 | 20 BCSG | 35 | |

Pictures

About Us

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a professional supplier for oilfield products according to the API standard.

Our products have exported to USA, Canada, Egypt, India and UEA, etc with 40 FCL containers per month. Now, with high quality and short supply and good service, our products have got good reputation home and abroad .

Here we got some prise as follows

Quality Systems

1\Quality control of the raw material:

1)The selection of the raw material supplier:our raw materials mainly include alloy structural steel, stainless steel, non-ferrous metal alloy and high nickel alloy, etc, in the selection of the raw material suppliers, we would do the comprehensive assessment of the supplier strictly according to technical requirements .Most of our suppliers are the leading enterprises of the steel production in China and the special alloy are usually purchased from abroad to ensure a higher mechanical properties.

2) The acceptance & Inspection of the raw material:

Ultrasonic flaw detection for every piece of the steel.

Chemical composition analysis for every piece of the steel.

Mechanical performance test for every piece of the steel..

2\Quality control of the seals:

1) O Rings: 100% visual and dimensional inspection for every piece of the O-rings, 15% spot check for the size and hardness test of the o rings. As for the sealing and heat resistance properties of the o rings, we designed a special test device which is equipped with heating insulation equipment that can simulate the down hole temperature and pressure. At present, our fluorine can keep a good performance in the condition of 210 ℃, and 105 Mpa work pressure (maximum pressure ever reached 146).

2) Back-up ring: 100% visual and dimensional inspection for every piece of the back-up ring, as for the test of the sealing and heat resistance, we design and manufacture the special test device, equipped with heating insulation equipment to stimulate the down hole temperature and pressure for acceptance. At present, our company's high pressure back-up seal can keep good sealing performance and deformed a little in the condition of 210 ℃, and 105Mpa work pressure (maximum pressure ever reached 146). It can be used for many times.

3. Quality control of the spring: Apart from the conventional test of the raw material and size of the different springs that used in the tools, we specially designed a test device that equipped with heating preservation equipment to stimulate the down hole temperature and condition to test the spring performance.

4. Quality control of the spare parts processing:

1) Spare parts processing control:In strict accordance with the process and traceability requirements, a test, mark and record of dimension, geometric tolerance and for every piece and every procedure will be conduct.

2) Heat treatment quality control: We have two high temperature heat treatment furnaces that are mainly used for stainless steel and other special material heat treatment. For other materials, we entrust Baoji Petroleum Machinery Company Heat Treatment Plant to do the heat treatment. For the inspection of the heat treatment, we are equipped with the special inspection machine such as gantry hardness tester, digital universal tensile tester etc.

5. Quality control of the tool assembly and testing process

1) Test equipment: in addition to the conventional hydraulic test pump, tensile testing machine, we also have a pressure sensor and data acquisition system which can accurate and clear record each step of the test.

2) Technical documents: We have a test acceptance list for every tool test that clearly guides the each step of the test.

3) Assembly test: A special inspector will supervise the whole assembly process.

If any inquiry, pls contact me freely.