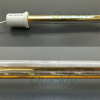

Molybdenum disilicide (MoSi2) heating element is a resistance generate-heating component made from MoSi2 or the basic material. It is used in high temperature under the oxidizing atmosphere, it looks like glass in its surface and form a light SiO2 glass film which can protect the element not to be oxidized. So this kind of element has unique effect for resisting oxidization in the high temperature. It is used to the highest temperature up to 1800 degree celsius during oxidizing atmosphere. According to your request, our company can produce the products of Pole, "U", "W" and "U"-right angle shapes, etc

Having the same mechanical character as other ceramic products , MOSI2 heating elements are brittle materials so that they are easy to rupture at the normal temperature , which brings some difficulties to transport and install , but it may be avoided if they were installed and used correctly .

PHYSICAL PROPERTIS

volume density : 5.5~5.6kg/cm3

bend strength : 15~25kg/cm2

vickers-hadness : (HV) 570KG/MM2

POROSITY RATE : 7.4%

WATER ABSORTION : 1.2%

HOT EXTENSIBLITY : 45

CHEMICAL PROPERTIES

Oxygen -resistance under high temperature : in oxidizing atmosphere , a layer of compact quarts (sio2) protective film is formed on the surface of element owing to the high -temperature combustion , which prevent MOSI2 from continuously oxidizing .When he element temperature is higher than 1700 degree . the sio2 protective film will be fused because its fusing point is 1710 degree celsius and the sio2 is fused nto molten dropa owing to the action of its surface extension ,whic cause losing its protective ability . In the oxidizing atmosphere, when the element is continuously used , the protective film forms again .

It should be point out that element cnnot be used for rather longtime in 400-700 degree celsius . otherwise it will be powdered owing to the strong oxidizing action in low temperature .

USAGE :

MoSi2 heating element can usually make use of furnace temperature from 1300 degree celsiusto 1800 degree celsius It is extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacture, etc.. It is an essential ideal element when the products are sintering in the high temperature