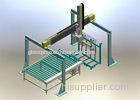

Large Glass Auto Unloading Machine , Loading And Unloading Equipment Instead of Manual Operation

Specifications:

|

Model |

YL2013 |

YL2518 |

|

Max.Size of Glass |

2000*1300mm |

2500*1800mm |

|

Min.Size of Glass |

350*350mm |

1200*1200mm |

|

Table Height |

900-950mm |

900-950mm |

|

Glass Thickness |

3-6mm |

3-12mm |

|

Speed |

3-10m/min |

3-10m/min |

|

Loader Frequency |

4-5 pcs/min |

4-5 pcs/min |

|

Total Power |

3.75kw |

4.5kw |

|

Floor Space |

3600*2700*3900mm |

4000*3200*4500mm |

|

Weight |

2500kg |

3500kg |

Note: We can produce customize machine according to your requirements.

Applications:

The Large Glass Auto Unloading Machine , Loading And Unloading Equipment Instead of Manual

Operation is very suitable for unloading various kinds of flat glass, such as solar glass, which has the high

automatism and steady performance in the glass deep processing. It is mainly used in loading the glass

from another device automatical, such as glass straight-line double edger, glass washing machine. Put

the glass in the specified location, after turning on the machine, the sucking begin to work. After it sucks

the glass already, put it on the roller table, transfer the glass to the frontend device automatically. Whe

it is need to adjust both the speed of transmission and the loading glass quantity, the operators modify

the corresponding parameters on the touch screen by both PLC automatic control and manual control in

the whole process, but manually control is primarily used in adjustment and maintenance, each action can

be done separately.

Description:

1. Horizontal motion mechanism, lifting mechanism, roll-over stand on the left side of the beam,on the right

top of the conveyor table.

2. After signal is given, sucking frame transverse moves to the glass stacking frame,and stop at specific

location, the stroke and speed can be controlled by PLC.

3. Arrived at the specified location, the movement of sucking frame becomes from horizontal to vertical

quickly,and be controlled by PLC.

4. After arrived at the specified location, the movement of sucking frame becomes from vertical to

horizontal slowly,and then moves on the surface of the glass,with PLC control.

5. When the detection switch,which is near the suction cups, in contact with the glass, the traverse motor

will stop working, meanwhile the vacuum system begins to work,and the suction cups begins to absorb the

glass.

6. When the vacuum pressure reaches the pressure setting pressure,the vacuum pump stop working, and

the lifting mechanism of the suction cups will rise up 20-30mm, in this location, it’ll stop about few seconds

for ensuring the single piece glass was well sucked up, finally the lifting mechanism vertical up quickly,

and then stop at the specified location.

7. When it arrived at the specified location, the sucking frame back to the origin horizontally and

overturn quickly,keep balance with the transfer table.

8. After arrived at the specified location, the movement of sucking frame becomes from horizontal to

vertical quickly, with PLC control.

9. About 20 mm from the glass surface,the suction cups release the glass by blowing the compressed

air. After the location by the transfer table, the glass quick transferred to the front-end equipment.

10. When the suction cups are blowing the compressed air, the lifting mechanism move up and back to

the origin,roll-over stand overturn and back to the origin too.Meanwhile the glass released from the signal,

and continue to work automatically.

Competitive Advantage:

1.It makes glass move easily and solves the difficulties of glass loading and unloading.

2.To improve the whole line automation, efficiently reduce the labor cost and the risk of industrial

injury by manual work.

<