Sesame Hulling Production Line Introduction

Sesame seed has a thin shell or husk. The process which can remove the husk is known as hulling. Hulling of sesame seeds is the precondition of enlarging application of sesame in food field. Sesame hulling production line is designed to hull the sesame seeds full automatically. The sesame hulling machinery has high production efficiency and high peeling rate, low maintenance and energy-saving.

Sesame Hulling Plant Features

1. Compact structure, special design, easy to clean and maintenance.

2. High peeling rate of 99%.

3. Fully automatical, easy to operate, energy-saving.

4. Low rate of repair and maintenance.

5. High production efficiency and perfect product.

6. Designed by computer-assistant engineering and high technology

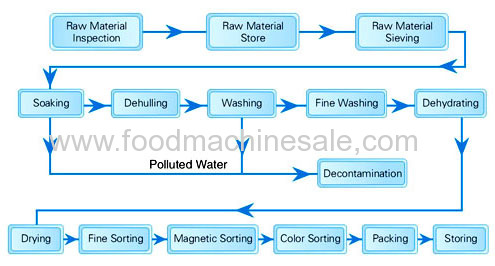

Sesame Hulling Line Technology Flowchart

The process of hulling consists of preliminary cleaning and grinding, hot lye treatment, removal of the skin and pigments, thorough washing and drying.

* Soaking process: The purpose of soaking is to make hull of sesame seeds soak in water totally for peeling off easily. The project use lye, soaking raw sesame seeds in a certain temperature, which improve the speed of infiltration ratio of water into hull, shorten the soaking time greatly to 30-40 minute from original 7-8 hours.

* Hulling process: The hull will be removed from the kernel by the relative friction between sesames by sesame hulling machine.

* Separating process: It is the key process in sesame seeds production, affecting final yield of finished product. This plant uses separation theory by different geometrical sizes of hulls and seeds. It uses best soaking technology to soften hulls, then uses hulls smaller than seeds to take away the hulls with water flow in subsidence-type automatic separator.

* Washing process: The hulled sesame seeds is cleaned and shifted by sesame washing machine, which can remove the stones, mud, chaff, dust and any other impurities from the sesame seeds efficiently.

* Drying process: The process use single chamber fluid bed drier. The sesame seeds float in hot air flow and polish by friction between seeds, which decrease sticky hull rate and improve the smoothness of finished product.

Application of Hulled Sesame Seeds

Hulled sesame seeds are softer and tastier than unhulled seeds. So the hulled sesame seed has extensive use in the food industry, which can be used to produce hulled sesame paste, upscale cakes, biscuit, hamburger, aviation food, upscale candy, moon cake, roast, and which is the important condiments to improve the color and aroma of dishes.