Technical Data:

1.Main Chemical Element: Al2O3≥75% , Fe2O3≤5%, TiO2≤5%, SiO2 5%-20%, Else: slight.

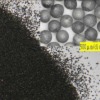

2. Shape: granular

3. Angle Factor: ≤ 1.1, very close to ball shape.

4. Bulk Density: 1.95-2.05 (g/cm3)

5. Refractoriness: ≥18000℃

6.Thermal Conductivity: 0.527W/M•K(1200℃);

7.Thermal Expansion : 0.13%(10 minutes at 1000℃)

Advantages of KUPPER Ceramsite:..

1. As Our Ceramsite is almost about half as light as zircon and chromite, it can turn out about twice the number of molds per unit weight,

and it can be handled so easily,saving labor and transfer power cost.

2.Less thermal expansion, so it makes the foundry more precisely, less cracking and high output. Improving foundry quality.

3. The shape of ceramic foundry sand is spherical with smooth surface and lower specific surface area so that can make the adhesive covered

uniformly. It has very good air permeability, good liquidity and good filling ability that can make the surface of foundry castings perfect when founded.

4. Ceramic foundry can flow very easily and easy to clean. Reducing usage amount of adhesive.

5. Ceramic foundry sand is a neutral material, so acid, alkali binder can be used.

6. Lower cleavage breakage rate: ceramic foundry sand has high density, very low cleavage breakage rate.,easily reclaimed and these makes it more

environmently friendly.

7. High refractoriness and service temperature can reach 1900°C, much higher than other foundry sand.

8. Recycle and regeneration use

9. Environment-friendly.Silica Sand causes too much dust that may bring anthracosis to the workers.

Chromite sand will cause heavy metal pollution bescause of the chromium and chromium compound

PS:The main performance comparison of ceramsite,Chromite sand and Zircon Sand

NAME | Particle Shape | Refractoriness ℃ | Reclaimation rate | Bulk Densityg/cm3 | Binder Amount

| Price | Mohs' hardness | Thermal Expansion | Environment |

Silica sand | irregular | Around 1750 | Low | 1.4-1.5 | cheap | 7 | High | dust pollution | |

Kupper Ceramsite | Very close to sphere:it brings good air permeability&flowability | ≥1800 | High | 1.95-2.05 | Less than 30%-50% comparing with other sand | modestly priced | 8 | Low | environment-friendly |

Chromite Sand | Irregular | 1830 | Low | 2.6-2.7 | modestly priced | 5.5-6.5 | Low | heavy metal pollution | |

Zircon Sand | irregular | 2340-2550 | high | 2.9-3.1 | Very expensive | 7.5-8 | Very low | radioactive pollution |

Technical Data:

1.Main Chemical Element: Al2O3≥75% , Fe2O3≤5%, TiO2≤5%, SiO2 5%-20%, Else: slight.

2. Shape: granular

3. Angle Factor: ≤ 1.1, very close to ball shape.

4. Bulk Density: 1.95-2.05 (g/cm3)

5. Refractoriness: ≥18000℃

6.Thermal Conductivity: 0.527W/M•K(1200℃);

7.Thermal Expansion : 0.13%(10 minutes at 1000℃)

The Kupper Ceramsite distribution specification can be designed according customer's specific requirement.

Spec | 10 | 14 | 20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS Range |

1700 | 1180 | 850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

200# | ≤5 | 10-30 | 30-50 | 15-35 | ≤5 | 15-25 | |||||||

300# | ≤10 | 25-45 | 35-55 | 5-15 | ≤5 | ≤2 | 25-29 | ||||||

400# | ≤10 | 25-45 | 20-40 | 15-25 | ≤7 | ≤5 | 35-39 | ||||||

500# | ≤3 | 15-25 | 25-40 | 25-45 | 10-20 | ≤10 | ≤5 | 45-55 | |||||

600# | ≤10 | 10-30 | 30-50 | 15-35 | 5-20 | ≤5 | ≤2 | ≤1 | 55-65 | ||||

650# | ≤8 | 10-25 | 20-40 | 20-40 | ≤15 | ≤7 | ≤2 | ≤1 | 60-70 | ||||

750# | ≤10 | 5-25 | 25-45 | 20-40 | ≤15 | ≤5 | ≤2 | 75-85 | |||||

1000# | ≤3 | 10-30 | 35-55 | 15-35 | ≤10 | ≤5 | 105-115 | ||||||

1250# | ≤2 | 5-20 | 30-50 | 25-45 | 5-20 | ≤8 | 125-135 | ||||||

1500# | ≤5 | 5-25 | 40-60 | 25-40 | ≤15 | 160-170 |

aluminachina.com