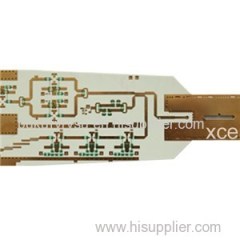

Multilayer Rogers4003 Immersion Gold PCB BoardSpecification: Base materialRogers 4003CBoard THK1.6mmLayer2Board size8*6cmSurface finishImmersion goldLine space10milCopper THK3OZLine width10 milQuick detail:

Rogers 4003 substrate

2 layer Rogers 4003pcb material

Green solder mask,

white silk screen

Model:XCER-1

Size:8*6cm

Location:ShenzhenApplication:

aTelecom: transmitter. Receiver. Oscillator. Antenna.

b Satellite receiver

c Global location system, amplifier, satellite telecom

d Microwave transmission

e Automobile telephone

f Measure apparatus, LSI inspector, analyser, signal oscillator

g High frequency teletcom, high speed transmission, high security, high transmission quality, high memory transaction

Rogers pcb material in stock: Brand Model Thickness(mm) DK(ER) RogersRO40030.254 0.508,0.813,1.5243.38RO43500.254 0.508,0.762,1.5243.5RO58800.254.0.508.0.7622.2RO30030.127,0.508,0.762,1.5243RO30100.63510.2RO32060.635MM10.2R030350.508MM3.5RO60100.635MM, 1,27MM10.2Multilayer rogers 4003C PCB DATA SHEET:

The methods employed to achieve low resistance electrical connections and good mechanical integrity fall into two categories: true fusion welding,

where the metals of the lead and the circuit pad are melted, and a form of diffusion where the joint is made without melting.

Welded Bonds: 1) Resistance Welding — The lead and circuit conductor are pressed together and a high current pulse (usually from a capacitor) passed between the two. Heat caused by the passage of the current through the resistance of the joint melts and welds the metal. 2) Parallel Gap Welding — This is a specialized form of resistance welding. In this case the electrical energy is supplied to a pair of parallel electrodes, which are in contact with the device leads. The weld depends upon conduction of heat generated in the lead to the circuit pad to melt and fuse them together 3) Percussive Arc Welding — The lead and pad are held a small distance apart and an arc is generated by applying a short pulse of RF energy to ionize the gap, followed by a discharge from the capacitor. As the arc decays, a mechanical device forces the two heated surfaces together and completes the weld. 4) Electron Beam Welding — A beam of high-speed electrons is focused in a vacuum on the lead and pad held together. The energy of the electrons is absorbed, raising the temperature to the melting point of the metals. 5) Laser Welding — Energy is focused on the work piece by an intense, collimated, monochromatic light beam that is absorbed and raises the temperature to the fusion point. 6) Soldering — The lead and pad are coated with a low melting point alloy and pressed together. Heat is applied either locally (by a heating tool) or generally (by infrared or oven heating) to melt the solder and weld the two components together.

Diffusion Bonding: 1) Ultrasonic Welding — Diffusion of metal between the lead and pad is induced by clamping the two together and applying mechanical energy in the form of ultrasonic sound vibration. The metal surfaces are cleaned by friction, which also heats them, aiding in the diffusion process, but temperatures do not reach the melting point. 2) Thermal Compression Bonding — Metal diffusion in this method is accomplished by heat and pressure applied to the cleaned surfaces of the lead and pad. The temperature is insuffi cient to give a true fusion weld. 3) Thermosonic Bonding — This method is a combination of ultrasonic and thermal compression bonding. The work is preheated, and ultrasonic energy is supplied through a gold capillary. Again, the weld is achieved at temperatures below the fusion point of the metal.Place of Origin:ChinaBrand Name:XCEModel Number:XCER-1PortShenzhen,HongKongMinimum Order Quantity:1pcsPrice:negotiationPackaging Details:Inner:vacuum packed bubble bag Outer:carton boxDelivery Time:5-10 daysPayment Terms:T/T,western union,paypal,L/CSupply Ability:1, 000, 000PCS/week

Home >

Electronic & Electrical

>

Immersion Gold PCB Product Product Product

Immersion Gold PCB Product Product Product

Trade on HiSupplier, Worry Free Guarantee

•Trading safety, secure your money, lower the risk, protect both buyers and suppliers

•HiSupplier is a Chinese multinational company in U.S, it helps to coordination and order landing.

- Product Details

- Company Profile

- Product Reviews

Related Products

Didn't find what you're looking for?

Post Buying Lead or

contact our customer service specialist for help!

.jpg)