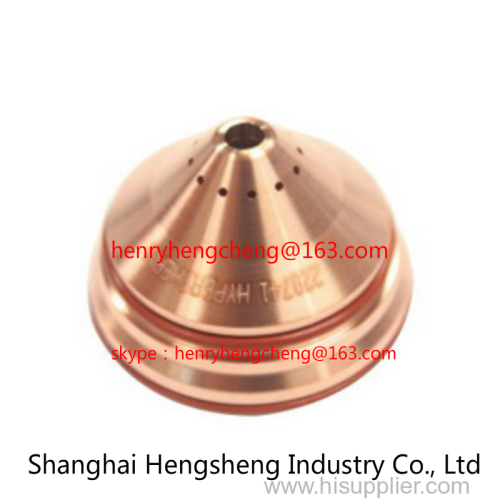

Hot Sell Hypertherm Shield 220707 400AMP Stainless Steel Plasma Cutting\Plasma Cutting Consumables HPR260XD 220762 Shield, Stainless Steel Plasma Cut

we have been sold in lots of countries and regions in Europe and Asia and gained good reputation widely with excellent quality

Our company produces :

2. Kjellberg consumables for HiFocus80i, HiFocus100i, HiFocus130i, HiFocus160i, HiFocus280i, HiFocus360i, HiFocus440i and so on.

3. Esab consumables for PT-25, PT-36, PT-37, PT-600, PT-15XL, PT-19XL, PT-31XL and so on.

4. Koike consumables for SUPER 400, SUPER 400 PLU.

5. Komatsu plasma consumables for 30KW, 60KW 3082, 3084, 3086, 6082, 6084.

plasma Cutting machine HPR130XD, HPR260XD, plasma consumables. Hypertherm plasma HPR260XD plasma cutting accessories.

Hypertherm HPR260XD plasma torch parts, Plasma Consumables, Plasma Torch Consumables, Plasma Cutter Consumables, Plasma Cutting Consumables, Hypertherm Plasma Parts, Hypertherm Consumables, Hypertherm Plasma Consumables, Hypertherm Torch Consumables, Hypertherm Machine Consumables, Hypertherm Plasma Consumables, Hypertherm Plasma Machine Consumables, Hypertherm Plasma Cutting Consumables, Hypertherm Parts, Hypertherm Plasma Parts, Hypertherm Torch Parts, Hypertherm Machine Parts, Hypertherm Plasma Parts, Hypertherm Plasma Machine Parts, Hypertherm Plasma Cutting Parts,

Machine | HEC NO. | Ref NO. | Description |

HPR 130 HPR 260 HPR 130XD HPR 260XD HPR 400XD | H03192 | 220192 | Electrode,30Amp |

H03552 | 220552 | Electrode,50Amp | |

H03187 | 220187 | Electrode,80Amp | |

H03181 | 220181 | Electrode,130Amp | |

H03352 | 220352 | Electrode,200Amp | |

H03435 | 220435 | Electrode,260Amp | |

H03649 | 220649 | Electrode,130Amp Bevel | |

H03541 | 220541 | Electrode,260Amp Bevel | |

H03665 | 220665 | Electrode,130Amp(silver Plus) | |

H03666 | 220666 | Electrode,200Amp(silver Plus) | |

H03668 | 220668 | Electrode,260Amp(silver Plus) | |

H03629 | 220629 | Electrode,400Amp | |

H73180 | 220180 | Swirl Ring,30Amp | |

H73553 | 220553 | Swirl Ring,50Amp | |

H73353 | 220353 | Swirl Ring,200Amp | |

H73179 | 220179 | Swirl Ring,80/130/260Amp(Bevel) | |

H73436 | 220436 | Swirl Ring,260/260Amp(Bevel) | |

H73631 | 220631 | Swirl Ring,400/400Amp(Bevel) | |

H13193 | 220193 | Nozzle,30Amp | |

H13554 | 220554 | Nozzle,50Amp | |

H13188 | 220188 | Nozzle,80Amp | |

H13182 | 220182 | Nozzle,130Amp | |

H13354 | 220354 | Nozzle,200Amp | |

H13439 | 220439 | Nozzle,260Amp | |

H13646 | 220646 | Nozzle,130Amp(Bevel) | |

H13542 | 220542 | Nozzle,260Amp(Bevel) | |

H13632 | 220632 | Nozzle,400/400Amp(Bevel) | |

H33754 | 220754 | Retaining Cap 30/50Amp | |

H33176 | 220176 | Retaining Cap 80/130Amp | |

H33355 | 220355 | Retaining Cap 200Amp | |

H33433 | 220433 | Retaining Cap 260Amp | |

H33603 | 220603 | Retaining Cap (Bevel) 130/260Amp | |

H33756 | 220756 | Retaining Cap 80/130Amp | |

H33757 | 220757 | Retaining Cap 200Amp | |

H33760 | 220760 | Retaining Cap 260Amp | |

H33635 | 220635 | Retaining Cap 400/400Amp(Bevel) | |

H33740 | 220740 | Retaining Cap (Bevel) 130/260Amp | |

H23194 | 220194 | Shield,30Amp | |

H23555 | 220555 | Shield,50Amp | |

H23189 | 220189 | Shield,80Amp | |

H23183 | 220183 | Shield,130Amp | |

H23356 | 220356 | Shield,200Amp | |

H23440 | 220440 | Shield,260Amp | |

H23645 | 220645 | Shield,130Amp(Bevel) | |

H23545 | 220545 | Shield,260Amp(Bevel) | |

H23761 | 220761 | Shield,200Amp | |

H23764 | 220764 | Shield,260Amp | |

H23636 | 220636 | Shield,400/400Amp(Bevel) | |

H23742 | 220742 | Shield,130Amp(Bevel) | |

H23741 | 220741 | Shield,260Amp(Bevel) | |

H43173 | 220173 | Retaining Cap 30/50/80/130Amp | |

H43398 | 220398 | Retaining Cap 200/260/(Bevel)130/260Amp | |

H43747 | 220747 | Retaining Cap 30/50/80/130Amp | |

H43637 | 220637 | Retaining Cap 200/260/400Amp(Bevel) | |

H83818 | 128818 | HPR torch assembly | |

H83162 | 220162 | Quick-disconnect torch | |

H83163 | 220163 | Quick-disconnect recepticle | |

H83706 | 220706 | Quick-disconnect torch | |

H83705 | 220705 | Quick-disconnect recepticle | |

H93571 | 220571 | Water Tube with O-Ring | |

H93340 | 220340 | Water Tube with O-Ring(30/50/80/130/200/260Amp) | |

H93700 | 220700 | Bevel water tube(mild steel-130A) |

Technical Support:

plasma cutting arc fault analysis

trode and the inner wall of the nozzle, resulting in high-frequency discharge, the gas ionization and the formation of local small arc, the small arc by compressed air, ejected from the nozzle to ignite plasma arc. This is main task spark generator. Under normal circumstances, the working time of the spark generator is only 0. 5 ~ 1s, can not be automatically cut off the reasons for the general control circuit board components, the discharge electrode gap between the spark generator is not suitable. Solution: should always check the spark generator discharge electrode, so that the surface is smooth, timely adjustment of the discharge electrode gap of the spark generator (0. 8 ~ 1. 2mm), if necessary, replace the control panel.

ce the consumed parts after removal of gas

In the replacement of consumption or for a long time after shutdown, should purge gas (2-3 minutes advisable) to ensure the removal of water and mist from the torch.

To keep the 12 cutting torch and expendable cleaning

It will greatly influence the plasma torch system in consumption and on the function of any dirt. Replacement parts when the consumption, to put it in a clean flannelette, should always check the torch of threaded connection, with hydrogen peroxide cleaning agent to clean the electrode contact surface and the nozzle.

The problem of plasma cutting

e sparks exist. If not, generally 110VAC did not come or fixed G1, G2 plastic board damp, damp after G2, G1 can not discharge and produce high pressure. Drying wood glue with a hair dryer to restore 110VAC. If there is still no guide arc, should check the high frequency arc, due to the high frequency of the skin effect, the high frequency line and the nozzle of the conductive ring is not good or because of the reasons for the sealing ring and the cooling water will not have a short circuit. Open the cutting gun, tighten the high frequency line or replace the sealing ring, generally can solve the problem.