Straw is a generic term for the stem and leaf (spike) of mature crops. Usually refers to the remainder of wheat, rice, corn, potato, rape, cotton, sugar cane and other crops (usually coarse grains) after harvesting the seeds.More than half of the crop photosynthesis products exist in the straw, straw is rich in nitrogen, phosphorus, potassium, calcium, magnesium and organic matter, is a multi-purpose renewable biological resources, straw is also a rough feed.

Straw is a low-carbon fuel, and sulfur content, ash content than the current large amount of coal is low, is a more "clean" fuel, in the effective sewage protection measures to develop straw power, will greatly improve the environmental quality, Environmental protection is very favorable. In rural areas to promote the implementation of straw power generation technology, saving non-renewable resources, ease the power supply and other aspects are of particular importance.

Rotary drum dryer is designed to dry Biomass Straw which contains high moisture.Heat is generate by hot air generator by Coal, gas, petrol,diesel, biomass fuel etc.Total system is automated & moisture in material is adjustable as per requirement in various sectors.Depending on raw material,moisture and required production we can suggest suitable model and an approximate cost of your system in a short time frame.And Continuous work can reduce the cost of your company.

Application

Application

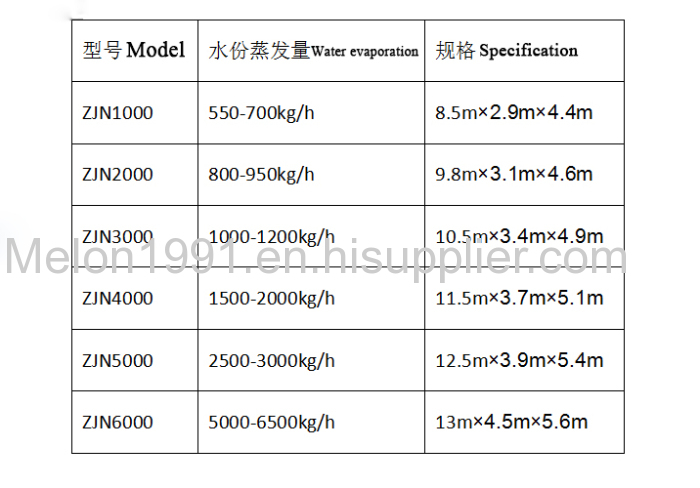

Specification

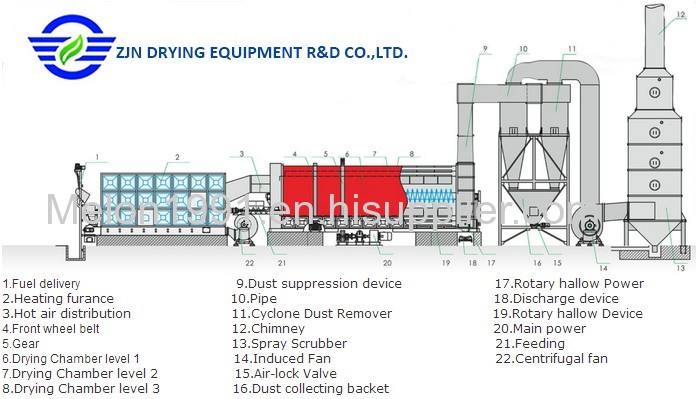

Schematic of structure

Schematic of structure

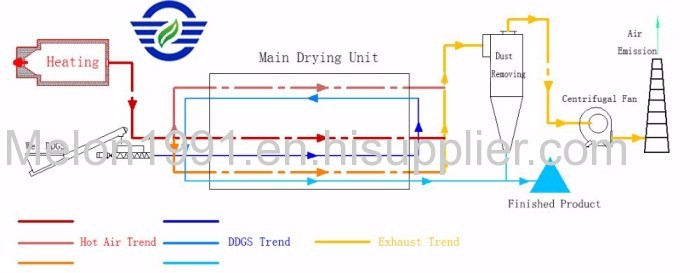

Working principle

Working principle

The hot air and wet Biomass Straw were sent into the main drying unit. Then the wet Biomass Straw and hot air will be sent into first stage of drying equipment,There is a special broken device in the first stage drying equipment. In this broken device, the wet Biomass Straw will be broken into scattered and "boiling suspended" state. With the hot air, the scattered Biomass Straw will be keeping rolling, rotation and separation. So the wet and sticky and blocking phenomenon of Biomass Straw is solved. Thus the important transformation "high humid —→ not humid, high sticky —→ not sticky, high viscous to not viscous" is completed.

The hot air and wet Biomass Straw were sent into the main drying unit. Then the wet Biomass Straw and hot air will be sent into first stage of drying equipment,There is a special broken device in the first stage drying equipment. In this broken device, the wet Biomass Straw will be broken into scattered and "boiling suspended" state. With the hot air, the scattered Biomass Straw will be keeping rolling, rotation and separation. So the wet and sticky and blocking phenomenon of Biomass Straw is solved. Thus the important transformation "high humid —→ not humid, high sticky —→ not sticky, high viscous to not viscous" is completed.

Water vapor produced in first stage drying process is automatically discharged at the end of first dryer. The scattered Biomass Straw are discharged into second dryer.The second dryer adopts reverse flowing and vortex drying technique, the drying efficiency is also intensified. At the same time, heat and mass transfer is strengthened, which leads to bound water extravasation and evaporation speed up. Water vapor is discharged at the end of the second dryer. Biomass Straw are automatically sent into the third dryer . The third dryer adopts interflow plus reciprocating drying technique,the wet Biomass Straw move slowly and reciprocating, while the dried ones move in advance and fast. Biomass Straw will be discharged automatically when they are dry enough as request.

Water vapor produced in first stage drying process is automatically discharged at the end of first dryer. The scattered Biomass Straw are discharged into second dryer.The second dryer adopts reverse flowing and vortex drying technique, the drying efficiency is also intensified. At the same time, heat and mass transfer is strengthened, which leads to bound water extravasation and evaporation speed up. Water vapor is discharged at the end of the second dryer. Biomass Straw are automatically sent into the third dryer . The third dryer adopts interflow plus reciprocating drying technique,the wet Biomass Straw move slowly and reciprocating, while the dried ones move in advance and fast. Biomass Straw will be discharged automatically when they are dry enough as request.

Advantages

Special technology can take more energy-saving and efficient for you,and the main structure is consists of three different metal steel cylinder with different diameter, it can get a bigger evaporation area, and drying faster,letting the material make a full contact with the hot air;"Auto-Feeding Control device" can be regulated according to the moisture content of the material;"Negative pressure"working condition, clean work site and operating reliably.

Customer visit

Customer visit

Our Services

1)Pre-sale services: Enthusiasm and sincere

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

2)Sale services:Careful service

For your service to be exhaustive, so that you feel the seriousness of our team products and team customers intentions;

3)After-sale services: Faithfulness

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

4)After service

We provide one-year warranty to make sure your machine runs consistently. We always offering lifelong services and provide spare parts for a long term.

Certification

Company Information

Company Information

Established in 1991,ZJN Drying Equipment R&D Co., Ltd. Specializes in technology research, equipment manufacturing and project engineering for all kinds of humid andviscous materials drying.

Established in 1991,ZJN Drying Equipment R&D Co., Ltd. Specializes in technology research, equipment manufacturing and project engineering for all kinds of humid andviscous materials drying.

Taken"high efficiency, energy saving, practical" as the principle, Our company dedicates in innovation and developing technology for circular economy.

It has got excellent achievement in drying technology in term of high humid, viscous sludge and solid waste slag. It manages to keep in the front position in the rapid development of domestic drying technology field.

Based on advanced scientific management, integrity and pragmatic spirit, our company not only won more than 100 items of national patents but also awarded in succession many national honors and titles,

such as "scientific and technological achievements appraisal ", "China's top 500 private technology enterprise ", "the honest demonstration enterprise", In addition, our company has passed the ISO 9001:2008 international quality management system certification and so on.

NOTE:

In order to quota you the right machine with best price, we would like to get the following information include in your inquiry:

-What is the raw material you are going to dry?

-What is the start and ending moisture?

-What is the capacity per hour you need?

-What about the heat temperature?

-What kind of fuel you use to heat the dryer?

-How about dust collect requirements?

-Other special requirements?