China supplier plywood board formica high pressure laminate press machine

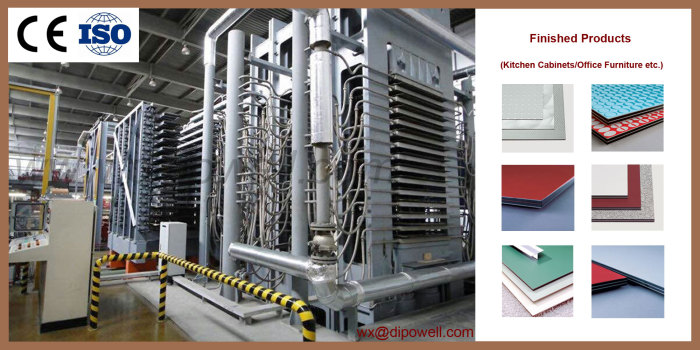

One side in-feed/out-feed system mainly consists of vacuum sucker, paper batching unit, conveyors, lifting in-feed/out-feed device, movable loading/unloading device, pusher-puller, hot press etc.

Step 1: Vacuum sucker set the paper stacks on paper batching unit

Step 2: Lifting in-feed device push each stack into movable loading device

Step 3: After all layers are full, movable loading device moves to front of hot press

Step 4: Pusher-puller push all layers into hot press one time.

Step 5: Hot press starts to press with heating and cooling simultaneously

Step 6: After finished, pusher-puller will pull out all layers into movable unloading device

Step 7: Unload finish panels one by one though lifting out-feed device and vacuum sucker.

Feature:

1,With Automatic thermo-measuring instrument, hydraulic system adopts large over-flowing, low-noise vane pump and high pressure plunger pump, can meet the technological requirements(closing time and working speed).

2,Hot platen is made of superior carbon structure steel, with fine grinding surface. Flatness≤0.06mm, smoothness 1.6. High precision, high strength, more durable.

3,The hot platen is filled with flexible metal hoses with reasonable layout, can quickly heat the hot platen.

4,The steam and cold water by turns can heat and cool the hot platens.