Product Description

Ductile Iron Socket Gate Valve ,cast iron butt weld gate valve ,Cast Iron Socket Gate Valve

About us:

Our factory is specialized in valves' production. As one of the biggest and most professional manufacturer and exporter majored in valves, we assure that we can provide our products with cheapest price, good quality and best service. If you like, welcome to our factory and have a look!

Product Feature

|

|

|

Technical Parameters

| Nominal diameter(mm) | 40~315 | 40~315 | |

| Nominal pressure(Mpa) | 1.0 | 1.6 | |

| Testing pressure | Shell(Mpa) | 1.5 | 2.4 |

| Seal(Mpa) | 1.1 | 1.76 | |

| Suitable temperature | -40°C~200°C | ||

| Suitable medium | Drinking water,sewage,seawater,food,medicines,gas,oil | ||

Main Raw Material

| Body | Disc | Stem | Actuator |

| CI | Ductile iron | Brass/Bronze | square nut/handwheel |

| DI | SS420/SS431/SS304 | gearbox |

Reference Standard

| Design standard | EN1171 SABS669 | |

| Testing standard | API 598 | |

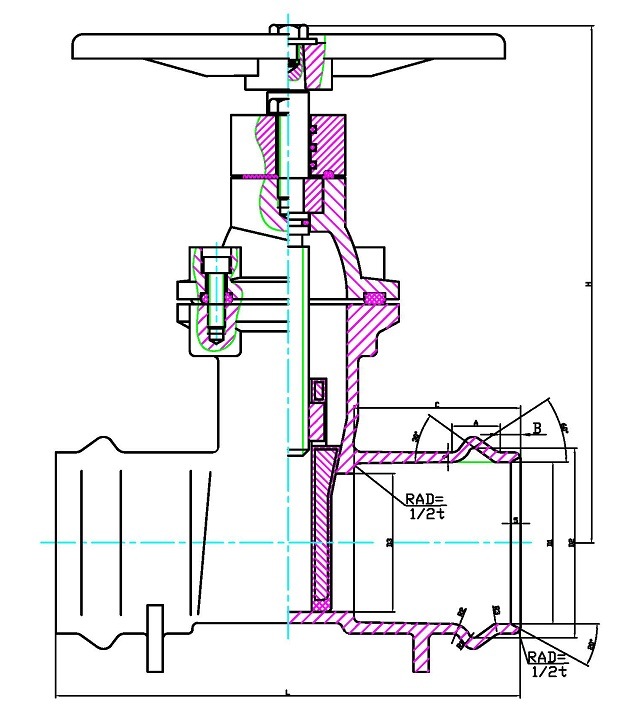

Overall Dimension

| Size | D1 | D2 | D3 | R1 | R2 | R3 | A | B | C | t | L | H |

| 40/50 | 50.8+0.7 | 65.3+0.8 | 40 | 5.0+0.8 | 8±2 | 16±2 | 29.9 | 11 | 90 | 6 | 335±1 | 230 |

| 50/63 | 63.8+0.7 | 80.2+0.8 | 55 | 5+0.8 | 8±2 | 16±2 | 32 | 15 | 90 | 6 | 335±1 | 250 |

| 65/75 | 75.8+0.7 | 94.1+0.8 | 65 | 5.5+0.8 | 9±2 | 18±2 | 35.7 | 15 | 110 | 6 | 335±1 | 275 |

| 80/90 | 90.9+0.8 | 110.9+0.8 | 78 | 6.0+1.0 | 10±2 | 19±3 | 39 | 17 | 110 | 6 | 335±1 | 306 |

| 100/110 | 111+0.9 | 132.7+0.9 | 98 | 6.5+1.0 | 12±2 | 21±4 | 43.1 | 18 | 110 | 7 | 355±1 | 337 |

| 150/160 | 161.2+1.1 | 186.2+1.1 | 140 | 7.5+1.2 | 17±2 | 27±5 | 52 | 22 | 120 | 7 | 405±1 | 429 |

| 200/200 | 201.4+1.1 | 227.8+1.4 | 178 | 8.0+1.2 | 18±4 | 30±7 | 56 | 24 | 135 | 7.5 | 450±1 | 522 |

| 225/225 | 227+1.1 | 255+1.4 | 200 | 8.5+1.4 | 18.5±4 | 30.5±7 | 58 | 26 | 135 | 8 | 450±1 | 522 |

| 250/250 | 251.7+1.1 | 282.8+1.4 | 228 | 9.0+1.6 | 23±4 | 37±7 | 66.5 | 27 | 150 | 8.5 | 500±2 | 599 |

| 280/280 | 282+1.1 | 312+1.4 | 250 | 10+1.6 | 20±4 | 65±7 | 72 | 27 | 150 | 8.5 | 500±2 | 599 |

| 300/315 | 317+1.2 | 351.5+1.6 | 293 | 10.5+1.8 | 24±5 | 55.7±7 | 77.5 | 30 | 170 | 8.5 | 550±2 | 689 |

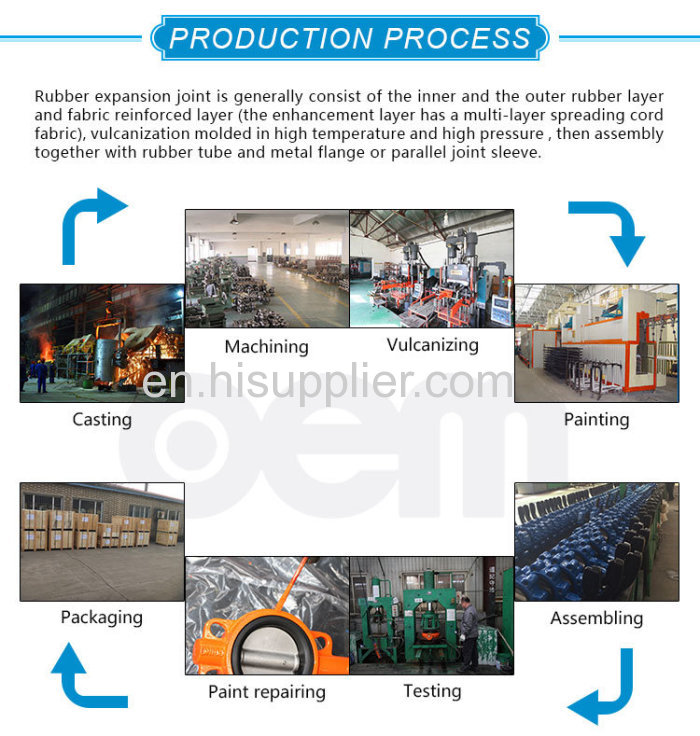

Machining Process

Other products

Why Choose US

Why Choose US

We control the material of PTFE(Teflon) and stainless steel wires per customer's request.

Some are from Japan and Taiwan, some are from China local. Only choose high quality material.

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Contact to this supplier

.jpg)