Steel-making by medium frequency furnace

We meet special requirements for materials . In order to guarantee the quality ,the company imported the spectrometer from Germany and is equipped with various testers,such as tensile tester,impact testing machine,metallography analyzer and so on .

Electro slag remelting

The ingot obtained by this remelting/refining process is very homogeneous and free of internal defects . The segregation of the ingot (called macro-segregations ) are substantially eliminated and the segregations of crystals (called macro-segregations ) are significantly reduced .

The ESR remelted material improve following mechanical characteristics :

Improved toughness due to increased homogeneity and isotropy

Improved creep resistance properties

Best fatigue strength and tenacity properties as well as outstanding tensile strength Improved purity

Forging steel

The largest electro-hydraulic hammer is 4.5 ton .And more than 6 skilled technicians work for us .After forging ,the inside microstructure becomes much closer and the metal grain size becomes much smaller . It can evevate the characteristics and quality of the knife ensuring a longer life .

Rough processing

No less than 40sets of processing equipment in the rough processing workshop , including lathe ,milling machine , planer , drill machine etc. Skilled workers are employed in its rough processing workshop .

Heat treatment

Our company has independent workshop for heat treatment . Couples of skilled technicians work here . Actually , most tools ( thickness ≤100mm) can be fully hardened . Thus ,the blades can be used after repairing until the size reached the minimum design dimension .

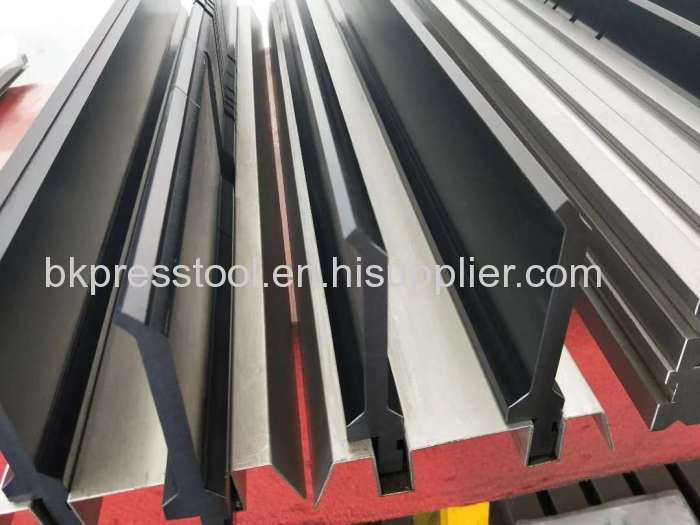

Finishing

Harsle has more than 35 sets of processing equipment including internal grinder , external grinder , surface grinder ,CNC grinder ,electric spark CNC wire-cut etc. The company can produce the shearing blades with 5500mm in length and slitting knives with 1300mm in outside diameter .

Testing

Various testers are put to use for testing its products in our company . They are including tensile tester , impact testing machine , metallography analyzer , harmless flaw detector , magnetic powder inspection , hardness tester , caliper rule , microcalliper , etc . Testing is carried out after each step . And every product has a unique track number . Thus it is easy to trace back anytime .