Best Price car floor mat cutting machine

Features of the Machine:

safety Device:Equipped with infrared automatic sensor device, the Safety Device provides a safe working environment.

High speed: Only need 80 seconds to finish one set of car foot mat., only need 6 minutes to finish one set of car cushion mattress

High efficiency: Don't need any die mould, or die mould cutting machine, this machine can press mark, cutting and moulding on soft material such as leather, carton etc. Save much labor and cost.

Accurate and Stable Working Table:The cutting table is build with aviation aluminum with honeycomb structure inside;sturdy,high-precision,stable for long-term running.

Low cost: one machine can do design, cutting instead of manual design and cutting, save labor, and material wastage cost.

Wide application: The car interior leather seat cushion cutting machine can cut leather, PU, fiber, EVA, XPE, sponge cladding, composite cladding, Sponge+drape+composite leather, PVC foot mat, paper, carton, plastic board etc. Soft material.

Good performance: Low noise, accurate transmission. Long lifespan and high precision.

High -precision automatic positioning system:With the high-definition CCD camera,locating and contour cutting can be realized on various materials automatically and precisely,which solves the problems of manual positioning so as to achieve a precise cutting result easily.aoyoo's diversifiled positioning mode meets different cutting requirements for different materials with the guaranty of the high precision of the contour cutting.

Specification:

| Technical parameters / model | AOYOO-1625-ZS6 | AOYOO-1825-ZS8 | AOYOO-2125-ZS10 | Accept unconventional model customization | ||

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Yaskawa servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI,PLT,DXF,CDR ETC | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

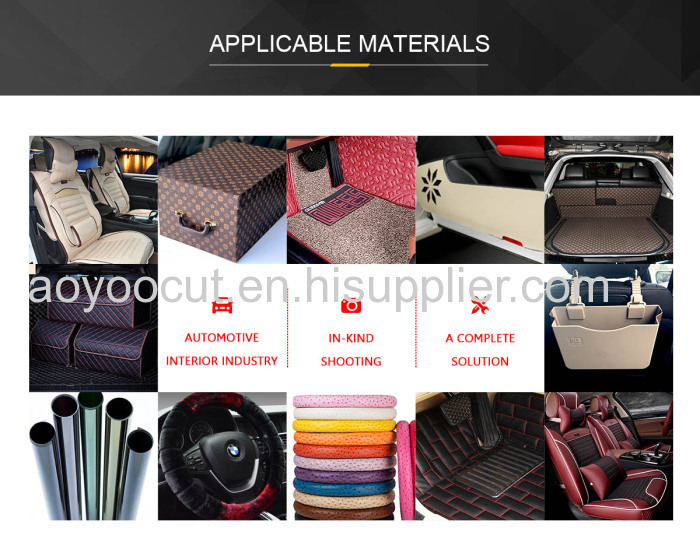

Application And Cutter Details

Car mats, foam compound, XPE, EVA, fabric carpet, imitation leather, leather, cloth etc. Applicable Industry: Automotive interior, composite materials, seal gasket, sports goods, safa fabric etc.

Our Package Advantage:

1, The pressure is strong, excellent quality stamping;

2, Table forward and backward rotation adjustment;

3, The stamping pressure, temperature, transfer time can be adjusted;

4, Automatic feeder, the collection of article, and adjustable;

5, Worktable elevating adjustable, convenient stamping workpieces of different heights;

6, The connecting rod design, Pressing maintain constant pressure.

our service

1)One year free warranty(except consumable parts), main parts are free of charge when problems happened because of quality problem during this period.

2).Life time free maintenance service.

3).Consumable parts(like blade, table cover) alway supply at cost price when needed.

4).A free operation training in our factory, and if don't have enough time, we will send

a detailed training video.

5).24 hours online service, free technical support with different languages.

6).Door to door technical support when needed.

Shandong AOYOO is one of the professional car interior leather seat cushion cutting machine manufacturers and suppliers in China, welcome to buy ourcar interior leather seat cushion cutting machinefrom Jinan and check the price with us.

About AOYOO

Shandong Aoyou CNC Equipment Co., Ltd. is a professional manufacturer of intelligent cutting equipment. The company specializes in providing cutting and engraving integrated solutions for the non-metal industry. In the environment of advocating environmental cutting, the company replaced the laser with a smart blade and developed a vibrating knife, a drag knife, a round knife and a half cutter.

Various tools such as beveling cutters, pressure rollers, punching knives, milling cutters, etc., combined and equipped, coupled with the assistance of large cameras and projectors, have basically met the cutting and engraving needs of all flexible industries.