Introduction

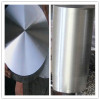

Zinc alloys are alloys based on zinc and containing other elements.Common alloying elements are aluminum, copper, magnesium, cadmium, lead, titanium and other low temperature zinc alloys.Zinc alloy has low melting point, good fluidity, easy fusion welding, brazing and plastic processing, corrosion resistance in the atmosphere, the crippled material is easy to recover and remelting;However, the creep strength is low and it is easy to change the size due to natural aging.Melting preparation, die - casting or pressure processing into wood.

According to the manufacturing process can be divided into cast zinc alloy and deformation zinc alloy.The main additions to zinc alloys are aluminum, copper and magnesium.Zinc alloys can be divided into deformation and casting zinc alloys according to processing technology.Cast zinc alloy with good fluidity and corrosion resistance, suitable for die casting instruments, automobile parts and other shell.

ZINC ALLOY INGOT Species

Traditional die casting zinc alloys are 2, 3, 4, 5, 7 alloys, the most widely used is no. 3 zinc alloy.In the 1970s, za-8, za-12 and za-27 were developed.

Zamak 3: good fluidity and mechanical properties.

Used for castings with low mechanical strength requirements, such as toys, lamps and lanterns, decorations, and some electrical appliances.

Zamak 5: good fluidity and good mechanical properties.

Used for castings with mechanical strength requirements, such as auto parts, mechanical parts, electrical components.

Zamak 2: used for mechanical parts with special requirements for mechanical properties, high requirements for hardness, good wear resistance and general requirements for dimensional accuracy.

ZA8: it has good impact strength and dimensional stability, but poor liquidity.

Used in die casting small size, precision and high mechanical strength requirements of the workpiece, such as electrical components.

Superloy: best fluidity for die-casting thin wall, large size, high precision, complex shape workpiece, such as electrical components and box body.

ZINC ALLOY INGOT supplier Use

Suitable for die-casting instruments, toys, lamps, decorations, electrical components and box bodies, auto parts, mechanical and electrical parts, mechanical parts, etc.

Zinc alloy: an alloy based on zinc and containing other elements.Common alloying elements are aluminum, copper, magnesium, cadmium, lead, titanium and other low temperature zinc alloys.Zinc alloy has low melting point, good fluidity, easy fusion welding, brazing and plastic processing, corrosion resistance in the atmosphere, the crippled material is easy to recover and remelting;However, the creep strength is low and it is easy to change the size due to natural aging.Melting preparation, die - casting or pressure processing into wood.According to the manufacturing process can be divided into cast zinc alloy and deformation zinc alloy.