Railway sleepers, also called railroad ties, railway crossties, or railway ties, are important railway components of the rail industry. Generally, the rail sleeper is always laying between two rail tracks to keep the correct space of the gauge.

Synthetic sleeper, also known as a composite sleeper, made of a composite material sheet produced by a foam extrusion process with continuous glass fiber as a reinforcing material(Fiber-reinforced Foamed Urethane), polyurethane as a matrix material, supplemented with additives. It has higher strength and widely used as a structural material, besides, it is light in weight, insulating and resistant to aging, heat-insulating, chemical-resistant.

China published the performance standard for Synthetic sleepers of fiber-reinforced polyurethane foam (CJ/T 399 - 2012).

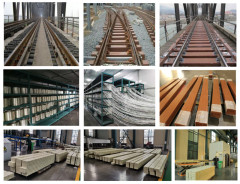

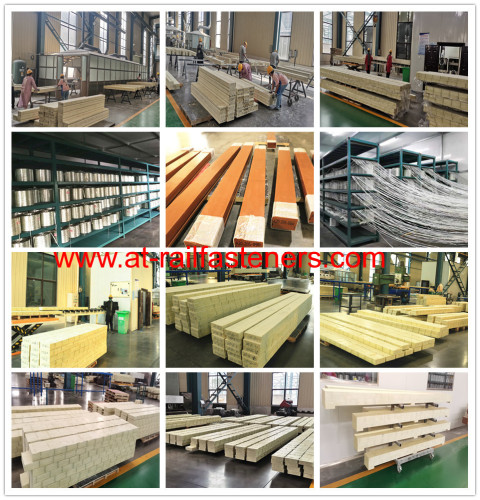

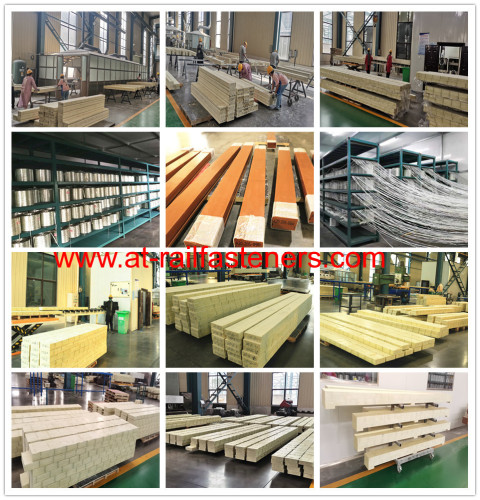

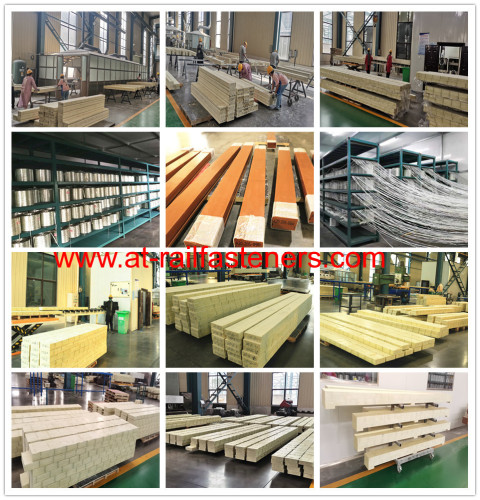

Anyang Railway Equipment Co., Ltd(AT) is a professional manufacturer of Composite Sleepers, compared with timber sleeper and steel sleeper, which are ideal for ballasted railway tracks, which have better damping and less wear.

The productivity of synthetic sleepers in Anyang Railway Equipment Co., Ltd(AT) is 10,000 Pcs/month.

The synthetic sleepers produced by Anyang Railway Equipment Co., Ltd(AT) have been used widely on all types of rail transport systems, particularly on switches, turnouts, bridges/viaducts, and other projects in high-speed and metro railway construction.

The shape of the composite sleeper is similar to that of an ordinary timber sleeper. The construction and installation process of composite sleepers is simple, and the composite railway sleepers can be sawed, planed, nailed, screwed, and glued with ordinary woodworking tools. The composite railway sleepers have a low thermal expansion coefficient and thermal conductivity, high anti-seismic, compressive, tensile, and flexural strength.

Composite sleepers can maintain good electrical insulation and stability even in long-term adverse weather conditions. The composite railway sleeper has better processing performance than the concrete sleeper. It is light in weight and can be processed into any length. It is not necessary to customize the mold for each length. After repairing the nail hole on the composite sleeper. It can be used again with long service life.

TECHNICAL FEATURES

Ambient temperature: -45 ℃ ~ 70 ℃

Machinability: The same as Timber.

Service life: More than 50 years.

Maintenance costs: significantly reduced.

Lifecycle costs: Minimal.

Density: The same as wood (740kg/m3).

Electrical conductivity: Very low.

Chemical resistance: Very high.

Custom manufacture: to millimeter precision.

Sustainability: 100% recyclable.

No. Test Item CJ/T 399-2012 Technical Requirement JIS E1203 Rrequirement Unit Anyang Railway Equipment Co., Ltd's Test Result by CRCC Test Center 1 Bending Strength ≥70 ≥70 MPa 1# 2# 3# 124 126 117 2 Flexural modulus ≥6 ≥6 GPa 4# 5# 6# 10 11 13 3 Longitudinal com pression strength ≥40 ≥40 MPa 7# 8# 9# 107 50 93 4 Shear strength ≥7 ≥7 MPa 10# 11# 12# 11 10 12 5 Adhesive shear strength ≥7(Base-material breakage) MPa 13# 14# 15# 10 8 12 6 Water absorption ≤10 ≤10 Mg/cm3 16# 17# 18# 4 3 4 7 The finished product resists bending load ≥170 ≥170 kN 19# 210 8 Screw spikes pullout strength ≥40 ≥30 kN 20# 21# 22# 44 46 58 9 Mass density 0.74±0.10 0.74±0.10 g/cm3 23# 24# 25# 0.72 0.65 0.68 10 Fatigue performance 105 times,No abnormality / 26# 105 times,No abnormality 11 Flame retardant After the ignition source is removed, there is no visible flaming or continuous flaming of the sample, but the front of the flame does not exceed the 25mm mark / 27# 27# 27# After the ignition source is removed, there is no visible flaming or continuous flaming of the sample, but the front of the flame does not exceed the 25mm mark After the ignition source is removed, there is no visible flaming or continuous flaming of the sample, but the front of the flame does not exceed the 25mm mark After the ignition source is removed, there is no visible flaming or continuous flaming of the sample, but the front of the flame does not exceed the 25mm mark 12 breakdown voltage ≥20 ≥20 kV 30# 31# 32# Thickness: 20mm Thickness: 20mm Thickness: 20mm 35 No breakdown 35 No breakdown 35 No breakdown 13 Surfance resistance ≥1*1010 ≥1*1010 Ω 33# 34# 35# 4.1*1015 4.1*1015 4.9*1015 Remark 1. Breakdown voltage: Sample size: 100*80*20mm (length*width*thickness), using unequal diameter electrodes in the air, ambient temperature: 20℃, humidity: 40%.

2. Surface resistance: sample size: 100*100*4mm (length*width*thickness), ambient temperature: 20℃, humidity: 40%, test voltage: 1000V.

3. Underlined items are unqualified items;From the above table, we can get the conclusion that China Synthetic sleepers Standard: CJ/T 399-2012 is almost the same as Japan Synthetic sleepers Standard JIS E1203, regarding the technical requirement on Screw spikes pullout strength, CJ/T 399-2012 is higher than JIS E1203.

From the above table, we can get the conclusion that the synthetic sleepers produced by Anyang Railway Equipment Co., Ltd fully comply with CJ/T 399-2012, and the test values are better than the required value shown in CJ/T 399-2012.