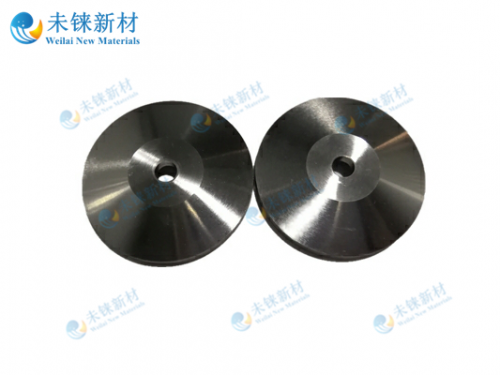

Anode target is the critical components of X-ray tubes, X-rays are generated from an anode target by electron bombardment. Since tungsten has a high melting point, a low vapor pressure, and can generate X-rays when irradiated with a high-speed electron beam, it is used as a target surface material in an anode target of various X-ray tubes. Because molybdenum has the high thermal conductivity and the fast heat dissipation, the application of molybdenum based tungsten target can contribute to increase heat storage capacity and decrease cracking of the pure tungsten target. Furthermore, comparing with pure molybdenum, TZM alloy is widely used as higher recrystallization temperature and better mechanical characteristic. The addition of rhenium allows the target to combine high strength, toughness, heat resistance and high precision. Hence, the anode plates of rotating anode tubes usually contain a 1 to 2 mm thin layer of tungsten-rhenium alloy deposited onto a plate of molybdenum or TZM.

The power of stationary anode X-ray tubes is restricted due to the impact of temperature on the focal spot. The focal spot is to be larger, the greater power of the anode but also the greater the image unsharpness of X-ray images created. This contradiction can be solved by the structure of rotating anode X-ray tubes.

Production Process:

Powder Preparation → Pressing → Sintering → Forging → Heat Treatment → Machining → Balancing →(Black Coating)→ Degassing → Inspection → Packaging

TZM-W | TZM-WRe | TZM-WRe Blackened | |

Diameter | Φ52.5-102mm | Φ52.5-102mm | Φ52.5-102mm |

Thickness | 7-21mm | 7-21mm | 7-21mm |

Target Angle | Normally 6°-18° | Normally 6°-18° | Normally 6°-18° |

Rhenium Content | _ | 1%,3%,5%,10% | 1%,3%,5%,10% |

(Other sizes can be customized as needed)

.jpg)