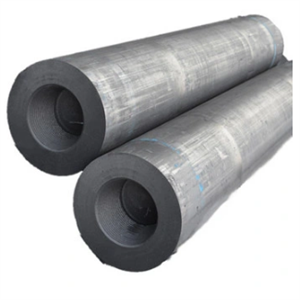

China manufacturer of rp hp uhp graphite electrode for eaf

Product Description

Graphite Electrode is made of high-quality low ash materials, such as petroleum bck, needle bck and coal pitch.after calcining,burdening,kneading,forming,baking and pressure impregnation, graphitization and then precision machined with professional CNC machining.such of the products own characteristics with low resistivity, good electrical conductivity ,low ash, compact structure,good anti oxidation and high mechanical strength, Widely used in LF, EAF for steel making industry, Non-ferrous industry, silicon and phosphorus industry.so it is the best conductive material for electric arc furnace and smelting furnace.

RP HP UHP Graphite Electrode with Nipple

Grade: RP/HP/UHP

Diameter: 300/350/400/450/500/550/600/700/800mm eaf graphite electrode

Specification

| Properties | UHP | HP | RP | ||

| φ300-500 | φ550-700 | φ300-700 | φ300-700 | ||

| Resistivity (uΩm max) | Electrode | 4.8-5.8 | 4.6-5.8 | 5.8-6.6 | 7.0-10.0 |

| Nipple | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | 4.0-4.5 | |

| Modulus of Rupture(Mpa) | Electrode | 10.0-14.0 | 10.0-14.0 | 10.0-13.0 | 8.0-10.0 |

| Nipple | 20.0-24.0 | 22.0-26.0 | 20.0-23.0 | 19.0-22.0 | |

| Young's Modulus(Gpa) | Electrode | 9.0-13.0 | 10.0-14.0 | 8.0-12.0 | 7.0-9.3 |

| Nipple | 15.0-18.0 | 16.0-19.0 | 14.0-16.0 | 12.0-14.0 | |

| Bulk Density (g/cm3) min | Electrode | 1.68-1.74 | 1.70-1.74 | 1.64-1.68 | 1.53-1.56 |

| Nipple | 1.72-1.82 | 1.80-1.84 | 1.75-1.80 | 1.70-1.74 | |

| CTE (100-600ºC) max | Electrode | 1.1-1.4 | 1.1-1.4 | 1.6-1.9 | 2.2-2.6 |

| Nipple | 0.9-1.2 | 0.9-1.2 | 1.1-1.4 | 2.0-2.5 | |

| Ash | 0.2-0.3 | 0.3-0.5 | |||

Dia (mm) | RP | HP | UHP | |||

| Current Load (A) | Current Density (A/cm3) | Current Load (A) | Current Density (A/cm3) | Current Load (A) | Current Density (A/cm3) | |

| 200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 | ||

| 225 | 6100-8600 | 15-21 | 6500-10000 | 18-25 | ||

| 250 | 7000-10000 | 14-20 | 8000-13000 | 18-25 | 8100-12200 | 20-30 |

| 300 | 10000-13000 | 14-18 | 13000-17400 | 17-24 | 15000-22000 | 20-30 |

| 350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

| 400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

| 450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-27 |

| 500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

| 550 | 32000-40000 | 13-16 | 37000-57000 | 15-23 | 42000-66000 | 17-26 |

| 600 | 38000-47000 | 13-16 | 44000-67000 | 15-23 | 49000-76000 | 17-26 |

Production Flow

Guidance of Using

Being hard and brittle ,artificialgraphite electrode shall be specially handled.Proper operationg may reduce the consumption and cost.

1. Professional tools should be used for hoisting graphite electrodes. It is strictly forbidden to use a crowbar to prevent impact damage during handling.

2. Graphite electrodes are prohibited from rain, snow and water, and should be kept dry. If it is found to be damp, it should be dried before use, the temperature should not exceed 100 ºC, and the drying time should not be less than 48h.

3. Do not stack near debris such as clay, slag, etc., so as not to pollute the surface of the graphite electrode and affect the conductive effect.

4. Before the graphite electrode is connected, carefully check whether the electrode connector hole is intact, whether the connector thread is damaged, and whether the connector bolt is lost. When the electrode is lifted, the electrode connector thread of the ground terminal should be prevented from being damaged.

5. Dust and debris in the joints and joint holes should be blown dry with compressed air.

6. Graphite electrodes must be tightly connected, and no tilt is allowed during connection. Torque wrenches should be used to prevent excessive force or too small, and the gap is not greater than 0.4mm.

7. The electrode holder should be clamped, not loose and in good contact, and no arc should be generated. Otherwise, the connection will be reddish, oxidized, thinned and broken.graphite electrode 600 eaf graphite electrode

8. If the electrode is lifted with a metal lifting plug, the thread in the joint hole must not be damaged. After lifting, the lifting plug should be unscrewed to prevent dust and debris from falling into the joint hole. arc furnace graphite electrode

9. When the electrode lifting device of the electric furnace is running, it should be kept stable. After the furnace cover is repaired, check whether the furnace cover is positioned correctly. During smelting, refractory materials are used to close the furnace lid to prevent the oxidation of the upper electrode of the flame in the furnace.

10. The holder should be clamped outside the safety wire of the electrode connector hole area. arc furnace graphite electrode uhp 600mm graphite electrode

11. When distributing the molten pool, the big piece is at the bottom and the small piece is at the top. Do not place the charge with poor conductivity on the top. During melting, the unmelted charge should be handled in time to prevent the collapsed material from breaking the electrode. graphite electrodes for furnace