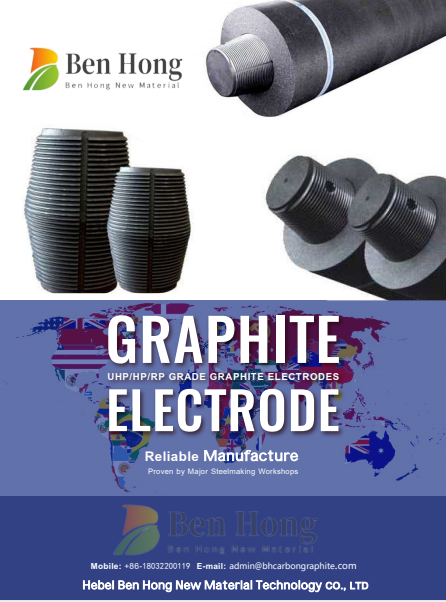

Company Profile

Graphite Electrode Factrory.

30 Years industrial experience.

Rich experience in Exporting by vessel, train and railway wagon.

Supply graphite electrodes RP/HP/UHP D100-D700mm

Strict quality control from raw materials to finished products

Advanced production technology and strong technical force.

Product Description

PRODUCT FEATURE

Has good electrical conductivity Strong thermal shock resistance

High mechanical strength Low consumption

Technical Data:

| Item | Classification | Unit | Nominal Diameter (mm) | ||

| RP | HP | UHP | |||

| 75-700 | 200-600 | 300-700 | |||

| Electrical resistivity (≯) | Pole Nipple | μΩm | 8.5 6.5 | 7.0 5.5 | 5.5 4.0 |

| Bending strength (≮) | Pole Nipple | Mpa | 7.0 15.0 | 10.0 16.0 | 11.0 20.0 |

| Young's modulus (≯) | Pole Nipple | Gpa | 9.3 14.0 | 14.0 18.0 | 14.0 22.0 |

| Bulk density (≮) | Pole Nipple | g/cm3 | 1.58 1.70 | 1.65 1.72 | 1.68 1.80 |

| Thermal expansion coefficient (≯) (100ºC-600ºC) CTE | Pole Nipple | ×10-6/ºC | 2.9 2.8 | 2.2 1.6 | 1.4 1.2 |

| Ash content (≯) | % | 0.5 | 0.3 | 0.2 | |

Packaging & Shipping

Packing: Wooden cases with pallet and steel belt fastening, make sure the packing is suitable to sea and train transportation.

Guidance of Using

Being hard and brittle ,artificialgraphite electrode shall be specially handled.Proper operationg may reduce the consumption and cost.

1. Professional tools should be used for hoisting graphite electrodes. It is strictly forbidden to use a crowbar to prevent impact damage during handling.

2. Graphite electrodes are prohibited from rain, snow and water, and should be kept dry. If it is found to be damp, it should be dried before use, the temperature should not exceed 100 ºC, and the drying time should not be less than 48h.

3. Do not stack near debris such as clay, slag, etc., so as not to pollute the surface of the graphite electrode and affect the conductive effect.

4. Before the graphite electrode is connected, carefully check whether the electrode connector hole is intact, whether the connector thread is damaged, and whether the connector bolt is lost. When the electrode is lifted, the electrode connector thread of the ground terminal should be prevented from being damaged.

5. Dust and debris in the joints and joint holes should be blown dry with compressed air. uhp graphite electrode manufacturer

6. Graphite electrodes must be tightly connected, and no tilt is allowed during connection. Torque wrenches should be used to prevent excessive force or too small, and the gap is not greater than 0.4mm. graphite electrode manufacturer

7. The electrode holder should be clamped, not loose and in good contact, and no arc should be generated. Otherwise, the connection will be reddish, oxidized, thinned and broken. arc furnace graphite electrode

8. If the electrode is lifted with a metal lifting plug, the thread in the joint hole must not be damaged. After lifting, the lifting plug should be unscrewed to prevent dust and debris from falling into the joint hole.

9. When the electrode lifting device of the electric furnace is running, it should be kept stable. After the furnace cover is repaired, check whether the furnace cover is positioned correctly. During smelting, refractory materials are used to close the furnace lid to prevent the oxidation of the upper electrode of the flame in the furnace.

10. The holder should be clamped outside the safety wire of the electrode connector hole area.11. When distributing the molten pool, the big piece is at the bottom and the small piece is at the top. Do not place the charge with poor conductivity on the top. During melting, the unmelted charge should be handled in time to prevent the collapsed material from breaking the electrode.

FAQ

Q: What information should I let you know if i want to get a quotation?

A: The required material dimension (diameter*length; if possible, please kindly supply us drawings). graphite electrode uhp 600

If it is possible, please also provide the application of products, we will recommend the most suitable products with details for confirmation.

Q: How can you control your quality?

A: For each production processing, We have a complete QC system for the chemical composition and physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

Q: What is your lead time?

A: It usually needs about 15- 20 days after receiving the PO.

Q: What are your payment terms?

A: We can accept a 30% deposit, 70% balance to be against the BL copy or by LC, or other payment terms. (according to your order value)

Q: Can we visit your company?

A: Yes, for sure, It's my pleasure to visit Our company.

Q: What is the shipping cost? graphite electrodes eaf

A: The shipping cost is determined by the destination port, weight, packing size, total CBM of the products, we will try best to get the most reasonable shipping cost from the forwarders or express couriers to help you save more money.