Product Introduction

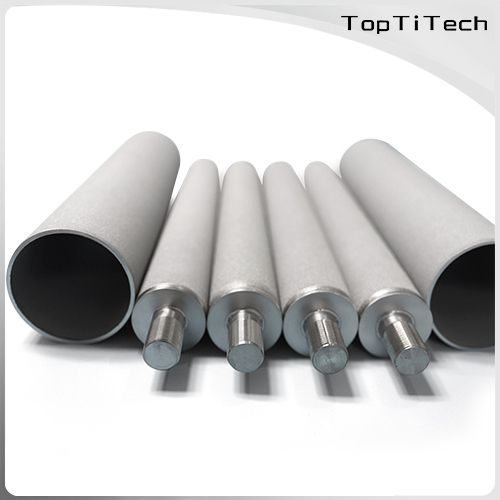

5um Porous Inconel 600 Metal Filter Element, which is a high-performance metal filter element. The filter element is made of high-quality Inconel 600 (Inconel 600) material, which has excellent filtration efficiency and corrosion resistance. It is designed for filtration and separation operations in a variety of demanding high temperature and corrosive environments. Whether in chemical, petroleum, food processing, or other industrial fields, this metal filter element can exert an excellent filtration effect.

The unique design of 5um Porous Inconel 600 Metal Filter Element enables it to effectively filter tiny particles and impurities, and its filtration accuracy can reach 5 microns. Whether it is liquid or gas, the filter element can efficiently capture suspended particles, solid particles, and other harmful substances, ensuring the purity and quality of the fluid. In addition, the corrosion resistance of Inconel 600 enables the filter element to operate stably for a long time in acidic, alkaline, and high temperature environments, prolonging the service life and reducing maintenance costs.

Parameter

Material: Inconel 600

Pore size: 5um

Size: φ50*155, φ60*185 or customized specifications

Interface: VCR 1/2 interface

Working Temperature: -200 - 1000°C

Technique: sintering

What is Inconel 600?

Inconel 600 (Inconel 600) is a superalloy with excellent corrosion resistance and high temperature strength. It is mainly composed of nickel and chromium and contains a certain proportion of iron and other alloying elements. Here is some basic information about Inconel 600:

Composition: The typical composition content of Inconel 600 is about 72% nickel and 14-17% chromium. In addition, it also contains up to 10-15% iron and small amounts of other elements such as copper, titanium and carbon. The composition of this alloy can be fine-tuned according to specific application needs.

Corrosion Resistance: Inconel 600 has excellent corrosion resistance in high temperature and corrosive environments. It can resist the erosion of many acidic media (such as sulfuric, hydrochloric) and alkaline media. It also has good resistance to corrosion from most organic and inorganic compounds.

High Temperature Performance: Inconel 600 has excellent high temperature stability and strength. It can maintain its mechanical properties and oxidation resistance in high temperature environment. Therefore, it is widely used in high temperature applications, such as petrochemical, aerospace, nuclear industry, etc.

Processability: Inconel 600 has good processability and can be formed by conventional hot and cold working methods. It can be processed and manufactured by hot rolling, cold rolling, forging, welding, and other processes.

Product Features

1. High flow capacity: 5um Porous Inconel 600 Metal Filter Element has excellent fluid handling capacity. Its design allows high flow rates through the filter element while maintaining consistent filtration, ensuring efficient fluid handling and production efficiency.

2. Compression resistance: The high strength and pressure resistance of Inconel 600 material enables 5um Porous Inconel 600 Metal Filter Element to withstand higher pressure. This makes it ideal for handling high pressure fluids while providing reliable filtration and separation performance.

3. Washable and Reusable: 5um Porous Inconel 600 Metal Filter Element can be maintained and reused through the cleaning process. Due to its corrosion resistance and high temperature resistance, the filter element is able to withstand cleaning and regeneration cycles, reducing waste and cost, and extending service life.

4. High Reliability: With the excellent performance of Inconel 600 material, 5um Porous Inconel 600 Metal Filter Element provides a reliable filtration solution. Its stability and durability ensure continuous filtration performance, reducing the risk of failure and downtime, thereby increasing the reliability and stability of industrial processes.

5. Wide range of applications: 5um Porous Inconel 600 Metal Filter Element is suitable for a variety of industries and applications. Whether it is chemical, oil and gas, electric power, food and beverage, or aerospace, the filter element can provide excellent filtration performance and meet the fluid handling requirements of different industries.

Application

1. Chemical industry: Used for chemical production, solvent filtration, and handling corrosive media.

2. Oil and gas industry: Applied in oil and gas extraction, refining, and natural gas processing for filtration and separation operations.

3. Power generation sector: Utilized for cooling water filtration in power generation equipment, circulation water system filtration, etc.

4. Food and beverage industry: Employed for liquid filtration in food processing, filtration of food additives, and more.

5. Aerospace industry: Used for crucial components such as fuel filtration in aircraft engines, turbine oil filtration, etc.

Pharmaceutical and biotechnology sectors: Applied in drug manufacturing, gas filtration in bioreactors, liquid filtration in biopharmaceutical processes, and more.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer´s designated place without damage.

Contact Us

TEL: +8619992203758

Company: TOPTITECH _ BAOJI YINGGAOCO., LTD

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China