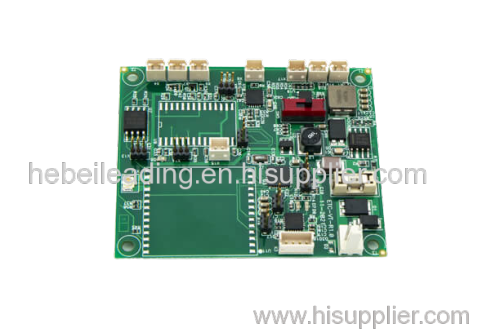

As one of turnkey PCB assembly suppliers, turnkey PCB assembly factories, turnkey PCB assembly manufacturers, we can do SMT and THT assembly on the same board and rich expertise like smartphone accessories, hardware, led lighting products etc.

Mixed PCB Assembly is a combination of through-hole and surface-mount PCB assembly techniques when filling boards.

The requirement of turnkey PCB assembly China is generated because some parts in the surface mount configuration are not available. Therefore, Mixed PCB Assembly arises at the right moment to solve this problem.

At Fastlink Electronics, the China turnkey pcb assembly factory, turnkey pcb assembly manufacturer, the combination of through-hole and surface mount PCB assembly technology is a very mature technology, you just give us your design, we will take care of the rest and providing you with the perfect product.

Types of components used in mixed PCB assembly

Mixed PCB assembly involves the use of different types of components to create a circuit board with a mix of through-hole and surface-mount technology. Here are some of the types of components commonly used in mixed PCB assembly:

Through-Hole Components

These are the components that have leads that pass through holes in the PCB and are soldered to pads on the other side of the board. Through-hole components have been used in electronic circuits for many years and are still used in many applications due to their durability and reliability.

Surface-Mount Components

These are the components that are mounted directly onto the surface of the PCB and do not require holes to be drilled into the board. Surface-mount components are smaller and more cost-effective than through-hole components and are commonly used in modern electronics.

Ball Grid Array (BGA) Components

These are surface-mount components that have an array of small solder balls on the underside of the package. BGA components are used in high-density designs where a large number of connections are required in a small area.

Chip-Scale Packages (CSPs)

These are surface-mount components that are similar to BGAs but have a smaller footprint and a higher pin count. CSPs are used in applications where board space is at a premium.

Dual In-line Packages (DIPs)

These are through-hole components that have two parallel rows of pins that extend through the PCB. DIPs are commonly used in older electronic designs and in applications where through-hole components are preferred over surface-mount components.

Quad Flat Packages (QFPs)

These are surface-mount components that have pins on all four sides of the package. QFPs are commonly used in microprocessors, microcontrollers, and other integrated circuits.

Small Outline Transistors (SOTs)

These are surface-mount components that are used for discrete components such as transistors and diodes.

These are just a few examples of the types of components used in mixed PCB assembly. The specific components used will depend on the design requirements of the circuit board.

Special Features of FastLink's Mixed PCB Assembly

Mixed PCB fab and assembly includes surface mount devices (SMD) and through-hole components. It brings out the combined advantages of both mounting technologies.

100% inspection using X-ray technology that helps in installation and reworks procedures

Lightweight

Increased stress-tolerance

High-reliability

High precision

Process flow of mixed PCB assembly

The process flow of mixed PCB assembly involves a series of steps that are typically followed to manufacture a printed circuit board (PCB) that contains a combination of surface mount technology (SMT) and through-hole components. Here is a general outline of the process flow for mixed PCB assembly:

Design and layout:

The PCB design and layout are created using computer-aided design (CAD) software. The design includes both SMT and through-hole components.

Stencil printing:

A stencil is used to apply solder paste onto the SMT pads of the PCB.

Component placement:

An automated pick-and-place machine is used to accurately place SMT components onto the solder paste. Through-hole components are manually inserted into the appropriate holes on the PCB.

Reflow soldering:

The PCB is heated in a reflow oven to melt and reflow the solder paste, creating a permanent bond between the SMT components and the PCB.

Wave soldering:

The PCB is passed through a wave soldering machine to solder the through-hole components to the PCB.

Inspection:

The PCB is inspected for defects and any necessary repairs are made.

Testing:

The PCB is tested to ensure that it functions as intended.

Final assembly:

The PCB is assembled into its final form, which may include additional components or packaging.

It's important to note that the specific process flow for mixed PCB assembly may vary depending on factors such as the size and complexity of the PCB, the specific components used, and the manufacturer's equipment and capabilities.

The Applications Of Mixed PCB Assembly China

Mixed PCB assembly is usually used in applications that require a combination of through-hole components and SMT components. You can find mixed technology and pcb and pcb assembly in the following applications:

Video processing

CPUs

Industrial controller assemblies

LED lighting products

Smartphone accessories

Communication hardware

Server boards

Common challenges in mixed PCB assembly

There are several common challenges that manufacturers may face when assembling mixed PCBs, which contain both surface mount technology (SMT) and through-hole components. Here are some of the most common challenges in mixed PCB assembly:

Component placement accuracy: SMT components are typically placed using automated pick-and-place machines, which require precise calibration to ensure accurate placement. However, through-hole components are often inserted manually, which can lead to inconsistencies in placement and an increased risk of misalignment.

Solder joint quality: The different soldering processes used for SMT and through-hole components can result in variations in solder joint quality. For instance, the high temperatures used in reflow soldering can damage through-hole components, while wave soldering may not adequately heat SMT components.

Thermal management: Mixed PCBs often contain both high-power components and sensitive components that are sensitive to heat. This can make thermal management a challenge, as it requires balancing the need for cooling with the risk of overheating.

Component availability: Some through-hole components may not be available in surface-mount versions, which can make it difficult to use them in mixed PCBs. Conversely, some SMT components may not be available in through-hole versions, which can limit design options.

Testing and inspection: Mixed PCBs may require more complex testing and inspection procedures to ensure that both SMT and through-hole components are functioning properly. This can add time and cost to the manufacturing process.

Design considerations: Designing a mixed PCB requires careful consideration of component placement, routing, and thermal management to ensure that all components fit and function properly. This can be challenging, especially for complex PCBs.

Why Choose Fastlink Electronics For Mixed PCB Assembly

Here are why our clients choose us reason :

Component selection: Choose components that are compatible with each other in terms of their electrical and mechanical properties. Ensure that the components are suitable for the intended application, and that they can withstand the environmental conditions of the operating environment.

PCB design: Design the PCB layout to ensure that the components are placed in the correct locations and that there is adequate clearance between the components. Use design rules to ensure that the traces have the appropriate width and spacing to avoid signal interference and crosstalk.

Assembly process optimization: Optimize the assembly process to ensure that the components are placed and soldered correctly. Use automated equipment where possible to reduce the risk of human error. Implement quality control measures to ensure that the assembly process is consistent and reliable.

Inspection and testing: Perform visual inspection and automated optical inspection (AOI) to detect defects and ensure that the components are placed and soldered correctly. Use functional testing to verify that the assembled PCB works as intended.

Documentation and traceability: Maintain detailed records of the assembly process, including component selection, PCB design, assembly process parameters, inspection results, and testing results. Use a barcode or RFID system to track the components and PCBs throughout the assembly process to ensure traceability.

By following these best practices, we can increase the likelihood of successful mixed PCB assembly and reduce the risk of errors and defects. At the same time, we can provide the much better quality for God (Clients).

Now, Please contact us by call or email ASAP, let's talk about your next a new PCB assembly project detail.