Features:

Pure Hand Made/Mouth Blown

High Quality Borosilicate Glass

Sophisticated Craftsmanship

Experienced Workers

OEM Standard Quality

Eco-friendly Products

Elegant and Innovative Design

Customized Products & Services

Fast Delivery Time

Various Payment Methods

Small Order Accepted

Company Introduction

Being dedicated in the field of Glass Drinkware and Smoking ware for more than one decades, C&C Glass wish to introduce itself to you as one of the leading manufacturers specialized in Borosilicate Double Wall Glasses (Double wall glass cups and double wall glass teapots), Glass Teawares (glass teapots, glass teacups, glass tea warmer,etc);Glass Coffee wares(glass coffee pots, glass coffee cups); Wine Glasses and Bar Glasses(Martini glasses,Cocktail glasses,Champagne glasses and beer glasses);Glass Decanter&Carafe; Glass Storage Jars; Glass Cruets; Glass Oil&Vinegar Bottles; Glass Water Pipes; Glass Bongs; Glass pipes; Glass Bubblers,etc

Borosilicate glass is a type of glass with the main glass-forming constituents silica and boron oxide. Borosilicate glasses are known for having very low coefficients of thermal expansion(~3 × 10−6 /°C at 20°C), making them resistant to thermal shock, more so than any other common glass.

In addition to the quartz, sodium carbonate, and aluminum oxide traditionally used in glassmaking, boron is used in the manufacture of borosilicate glass. The composition of low expansion borosilicate glass such as those laboratory glasses mentioned above is approximately 80% silica, 13% boric oxide, 4% sodium oxide, and 2-3% aluminum oxide. Though more difficult to make than traditional glass due to the high melting temperature required, it is economical to produce. Its superior durability, chemical and heat resistance finds excellent use in chemical laboratory equipment, cookware, lighting and, in certain cases, windows.

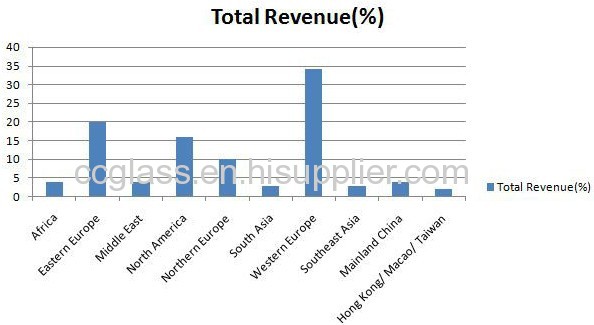

Overseas Market

How to Remove Hard Water Deposits From Glass

Excessive calcium and magnesium in water can cause chalky white deposits to form on glass surfaces. Drinking glasses, glass shower doors and windows are susceptible to hard water deposits. Hard water deposits make glass surfaces aesthetically unappealing and household cleaners less effective. Promptly neutralize the minerals deposits to prevent them from further bonding to the glass and becoming more troublesome to remove. Remove hard water deposits from glass surfaces using basic solutions and techniques.Instructions

- 1 Fill a plastic bucket with 1 gallon of warm water. Dissolve 1 tsp. of powdered water softener in the water.

- 2 Dampen a microfiber cloth in the solution. Wipe the glass with the damp cloth to neutralize and remove the mineral deposits. Always rinse the cloth with fresh water before dampening it in the solution.

- 3 Wipe the glass with clean paper towels until thoroughly dry.

- 4 Inspect the glass for remaining hard water deposits. If chalky white stains remain on the glass, fill a spray bottle with undiluted white vinegar.

- 5 Spray the vinegar onto strips of paper towels. Lay the paper towel strips directly on the hard water deposits. Keep the paper towel strips on the glass for an hour.

- 6 Peel the paper towel strips off the glass.

- 7 Dampen another microfiber cloth warm water. Wipe the glass with the damp cloth to rinse away the vinegar.

- 8 Wipe the glass with clean paper towels until thoroughly dry.